Exploring the Role of Caustic Soda in Soap Production and Its Benefits

The Role of Caustic Soda in Soap Making

Caustic soda, scientifically known as sodium hydroxide (NaOH), is a critical ingredient in the soap-making process. Its significance stems from its ability to facilitate saponification, the chemical reaction that transforms fats and oils into soap. This article explores the uses of caustic soda in soap making, its role in the saponification process, and the considerations surrounding its use.

Understanding Saponification

Saponification is the process by which fats and oils are reacted with a strong alkali, such as caustic soda, to produce soap and glycerin. During this reaction, the triglycerides (fats and oils) are broken down into their component fatty acids. When these fatty acids react with sodium hydroxide, they form soap molecules and glycerin as a byproduct. The unique properties of the resulting soap depend on the types of fats and oils used, as different fatty acids yield different soap qualities.

Uses of Caustic Soda in Soap

1. pH Adjustment Caustic soda acts as a powerful alkaline agent that raises the pH level of soap mixtures. This increased alkalinity is essential for the effective saponification of fats. By ensuring the right pH balance, caustic soda helps create a soap that cleans effectively and maintains a stable structure.

2. Versatile Soap Production One of the significant advantages of using caustic soda is its versatility. It allows soap makers to create a range of soap types, including hard soaps (like bar soap) and liquid soaps. By varying the amounts and types of oils used in combination with caustic soda, artisans can produce soaps that have different textures, consistencies, and cleaning properties.

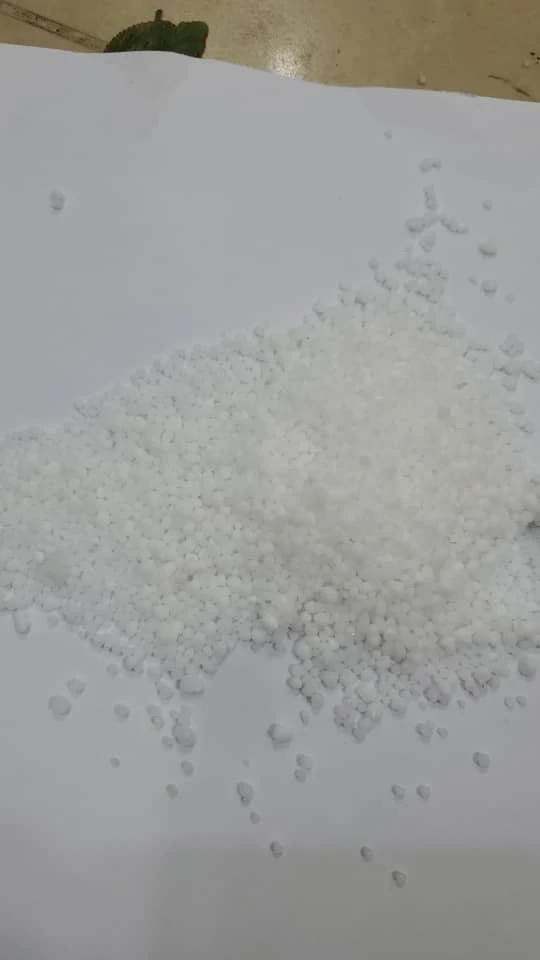

caustic soda uses in soap

3. Enhancing Cleaning Properties The presence of sodium hydroxide in soap contributes to its ability to emulsify oils and fats, making it effective at lifting dirt and grime from surfaces. This cleaning property is why soaps made with caustic soda are widely used in household cleaning products, personal care items, and industrial applications.

4. Glycerin Production As a byproduct of the saponification process, glycerin is produced when caustic soda is used in soap making. Glycerin serves as a humectant, attracting moisture to the skin and effectively enhancing the moisturizing properties of soaps. This makes soaps produced with caustic soda particularly appealing for personal care use.

Safety Considerations

While caustic soda is an essential component in soap making, it is also a highly caustic substance that can cause burns and other serious injuries if not handled properly. Safety measures are paramount when working with caustic soda. Soap makers should always wear appropriate personal protective equipment, including gloves and goggles, to prevent skin and eye contact. Additionally, it is crucial to work in a well-ventilated area to avoid inhaling any fumes.

Conclusion

In summary, caustic soda plays a vital role in the soap-making process through its function in saponification, versatility in producing various types of soap, and enhancement of cleaning properties. Its ability to produce glycerin adds to the benefits of soaps made with this alkali. However, safety precautions must always be observed to ensure a safe working environment. As consumers continue to seek effective and moisturizing cleaning products, understanding the role of caustic soda in soap making is crucial for recognizing the chemistry behind this essential everyday item.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025