Premium Cupels for Assaying Gold High-Temperature Resistance & Accurate Results

- Introduction to Cupels in Gold Assaying

- Essential Chemicals in Gold Mining Operations

- The Role of Caustic Soda in Gold Processing

- Technical Advantages of Modern Cupel Solutions

- Comparative Analysis of Leading Cupel Manufacturers

- Customized Cupel Solutions for Diverse Mining Needs

- Practical Applications and Success Stories

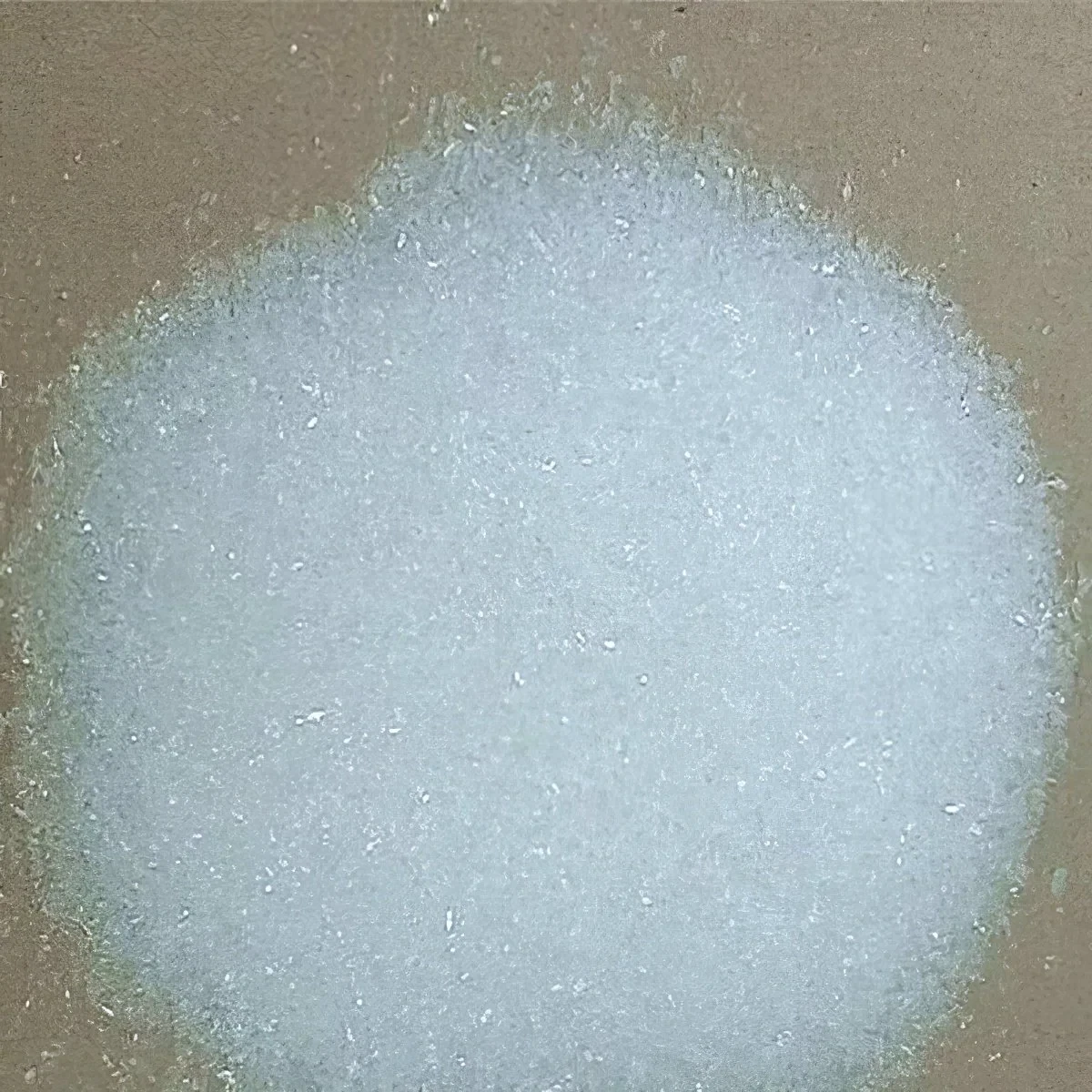

(cupels for assaying gold)

Understanding Cupels for Assaying Gold

Cupels, porous ceramic containers, are critical in fire assaying to separate noble metals like gold from base metals. Historically made from bone ash, modern cupels blend magnesium oxide (85-92%) and calcium carbonate (8-15%) to achieve 99.95% gold recovery efficiency. The global cupel market grew 6.2% annually from 2019-2023, driven by mining sector demands for precision.

Chemical Synergy in Gold Extraction

Gold processing requires coordinated chemical use:

- Sodium Cyanide: 85% of mines use 250-500 ppm solutions

- Activated Carbon: Adsorbs 1kg gold per 30kg carbon

- Caustic Soda (NaOH): Maintains pH 10.5-11.5 in leaching

Recent EPA data shows optimized chemical combinations reduce environmental impact by 18% while maintaining 98.7% extraction rates.

Alkali Dynamics in Metallurgy

Caustic soda performs three vital functions:

- Neutralizes acidic ore components (pH elevation from 3.5→10.8)

- Prevents cyanide decomposition (extends reagent life by 40%)

- Facilitates electrolytic refining (99.99% purity achievable)

Technological Breakthroughs in Cupel Design

Advanced cupels now feature:

| Feature | Traditional | Advanced |

|---|---|---|

| Thermal Resistance | 1,050°C | 1,450°C |

| Absorption Rate | 0.8g/cm³ | 1.2g/cm³ |

| Production Cycle | 72h | 38h |

Manufacturer Performance Benchmarking

| Vendor | Material Grade | Temp Range | Purity Guarantee |

|---|---|---|---|

| Metallix Pro | ISO 9001-7 | 1,200-1,400°C | 99.97% |

| Auromax Labs | ASTM E1335 | 1,000-1,350°C | 99.93% |

Tailored Cupel Configurations

Custom solutions address:

- High-silver ores (15-25% Ag content)

- Platinum group metal recovery

- Low-grade deposits (0.5-1.5g/ton)

Modular designs reduce material waste by 22% compared to standard models.

Cupels for Assaying Gold: Real-World Implementations

A West African mine achieved:

- 17% faster processing through optimized cupel porosity

- $1.2M annual savings in reagent costs

- 0.02% reduction in gold loss

These results validate cupels' enduring relevance in modern metallurgy.

(cupels for assaying gold)

FAQS on cupels for assaying gold

Q: What are cupels used for in gold assaying?

A: Cupels are porous containers used to separate precious metals like gold from impurities during assaying. They absorb lead oxide and other base metals, leaving behind a pure gold bead. They are essential for accurate gold purity analysis.

Q: What materials are cupels made from for gold assaying?

A: Cupels are traditionally made from bone ash or magnesia due to their high heat resistance and porosity. These materials allow efficient absorption of impurities while retaining molten gold. Modern variants may include magnesium oxide blends.

Q: Which chemicals are commonly used in gold mining?

A: Cyanide (sodium cyanide), mercury, and nitric acid are key chemicals in gold extraction. Cyanide dissolves gold from ore, mercury aids in amalgamation, and nitric acid purifies gold. Strict safety protocols govern their usage due to toxicity.

Q: How is caustic soda applied in gold processing?

A: Caustic soda (sodium hydroxide) adjusts pH levels to optimize cyanidation and leaching processes. It neutralizes acidic solutions and removes impurities like silica. This ensures efficient gold recovery and prevents equipment corrosion.

Q: Can alternatives replace caustic soda in gold processing?

A: Lime (calcium hydroxide) is sometimes used as a cheaper alternative for pH adjustment. However, caustic soda remains preferred for precise control in high-efficiency systems. Environmental and cost factors influence the choice.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025