Different Forms and Applications of Sodium Hydroxide in Various Industries

Types of Sodium Hydroxide Understanding Its Varieties and Uses

Sodium hydroxide (NaOH), commonly known as lye or caustic soda, is a highly versatile chemical compound with a wide range of applications in various industries. It is a strong base that is highly soluble in water, producing heat when dissolved. This article explores the different types of sodium hydroxide, their properties, and their uses in various fields.

1. Granular Sodium Hydroxide

Granular sodium hydroxide is one of the most common forms available. It is typically produced through the evaporation of water from sodium hydroxide solutions, resulting in solid granules. This form is favored for its ease of handling and dosing. Granular NaOH is widely used in industrial applications, particularly in the production of soaps, detergents, and textiles. Its high purity and concentration make it ideal for chemical processes that require a strong alkaline medium.

2. Sodium Hydroxide Pellets

Sodium hydroxide pellets are another prevalent type, which is created through the same evaporation process but is shaped into larger, uniform pellets. These pellets are easier to measure and use in various chemical reactions. They are primarily utilized in laboratory settings and industrial applications for pH adjustment, water treatment, and as a precursor for synthesizing other chemicals. Because of their compact form, they are also more convenient for shipping and storage.

Liquid sodium hydroxide solutions vary in concentration, typically ranging from 10% to 50%. This form is often used in industrial processes where liquid handling is preferred over solid forms. Liquid NaOH is essential in the paper and pulp industry, where it plays a critical role in the delignification process, breaking down lignin in wood fibers to produce pulp. Additionally, the liquid form is frequently used in water treatment facilities to neutralize acidic waste streams and to control pH levels.

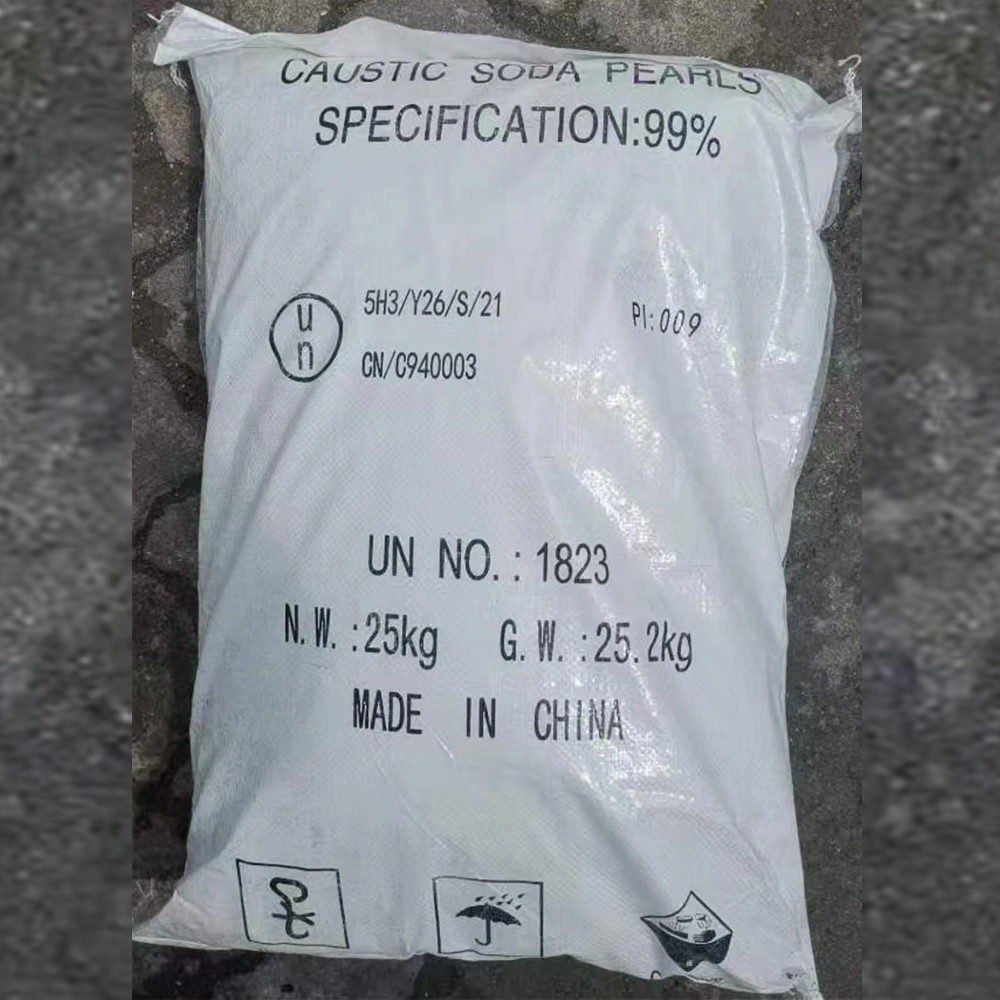

4. Bead Sodium Hydroxide

types of sodium hydroxide

Bead sodium hydroxide is a more specialized form, resembling small beads or pearls. This type is less common but offers certain advantages over granular and pellet forms, particularly in terms of reduced dust generation during handling. Bead NaOH is known for its uniform size, which improves its dissolution rate and makes it suitable for applications requiring quick reaction times. It is often used in chemical synthesis and various laboratory applications.

5. Applications of Sodium Hydroxide

Sodium hydroxide is integral to numerous industries due to its strong alkalinity and reactivity. In the food industry, it is used for food processing, such as in the production of olives and in processes to remove skins from fruits and vegetables. In the pharmaceutical industry, NaOH serves as a critical reagent in the synthesis of active pharmaceutical ingredients.

Moreover, sodium hydroxide is essential in the manufacture of biodiesel, acting as a catalyst in transesterification, whereby triglycerides are converted into biodiesel and glycerin. It is also vital for the production of various cleaning agents and is often found in household cleaners, drain openers, and oven cleaners due to its ability to break down organic materials.

6. Safety and Handling

Given its caustic nature, sodium hydroxide must be handled with care. It can cause severe chemical burns and damage to tissues on contact. Therefore, appropriate safety measures, such as wearing gloves, goggles, and protective clothing, are critical. Additionally, it should be stored properly away from moisture and incompatible materials to prevent hazardous reactions.

Conclusion

In summary, sodium hydroxide comes in various forms, including granular, pellets, liquid, and beads, each with specific applications across multiple industries. Its importance cannot be overstated, as it is a vital component in manufacturing, environmental management, and even food processing. Understanding the types of sodium hydroxide and their uses enables industries to select the appropriate form for their specific needs, ensuring safety and efficiency in operations. As research continues and industrial applications evolve, sodium hydroxide will undoubtedly continue to play a crucial role in technological advancements and industrial processes.

-

The Essential Guide to a Chemical to Disinfect Water: Safety, Applications, and Future TrendsNewsNov.20,2025

-

Chemicals Used to Disinfect Water – Key Solutions for Safe and Sustainable Water TreatmentNewsNov.20,2025

-

Best Chemicals Used to Disinfect Water – Comprehensive Guide & SolutionsNewsNov.19,2025

-

Comprehensive Guide to Chemical Disinfection of Water | Safe & Sustainable SolutionsNewsNov.18,2025

-

Bleach for Sanitizing Water – A Comprehensive Guide to Safe Water Treatment SolutionsNewsNov.18,2025

-

What Is Disinfectant Water? Uses, Benefits & Future Trends ExplainedNewsNov.18,2025

-

Comprehensive Guide to Chemicals That Disinfect Water for Global Safety and IndustryNewsNov.17,2025