liquid caustic soda manufacturers

Liquid Caustic Soda Manufacturers An Overview of the Industry

Liquid caustic soda, or sodium hydroxide (NaOH), is a highly versatile chemical with a wide range of applications across various industries. It is primarily used in the manufacturing of soaps, detergents, textiles, paper, and in water treatment processes. As demand for this essential industrial chemical continues to grow globally, the role of liquid caustic soda manufacturers becomes increasingly significant.

Understanding Liquid Caustic Soda

Liquid caustic soda is an alkaline solution that is produced through the electrolysis of sodium chloride (common table salt). This process not only yields caustic soda but also generates chlorine and hydrogen as by-products. Liquid caustic soda is characterized by its strong corrosive properties and its ability to dissolve organic and inorganic substances. Due to these properties, it must be handled with care, ensuring appropriate safety measures to protect workers and the environment.

Key Applications

Liquid caustic soda is utilized across a multitude of sectors

1. Chemical Manufacturing It is a fundamental ingredient in producing various chemicals, including sodium hypochlorite, which is used as a bleaching and disinfecting agent. 2. Pulp and Paper Industry In this sector, caustic soda is essential for the digesting process, breaking down lignin in wood and enabling the extraction of cellulose fibers for paper production. 3. Water Treatment Liquid caustic soda is employed to adjust pH levels in water treatment facilities, ensuring that drinking water meets safety standards. 4. Food Production In food processing, it serves a critical role in making alkaline solutions for peeling fruits and vegetables, as well as in the production of certain types of olives and pretzels.

5. Textiles It is used for scouring and bleaching in the textile industry, improving fabric quality and feel.

The Manufacturing Process

The manufacturing of liquid caustic soda involves several crucial steps

1. Electrolysis This is the primary method for producing caustic soda, typically using the diaphragm cell method, membrane cell method, or mercury cell method. Each method has its unique operational parameters and environmental considerations, particularly regarding the management of by-products like chlorine.

liquid caustic soda manufacturers

2. Concentration After electrolysis, the resulting solution is concentrated through evaporation or other methods to achieve the desired concentration of caustic soda.

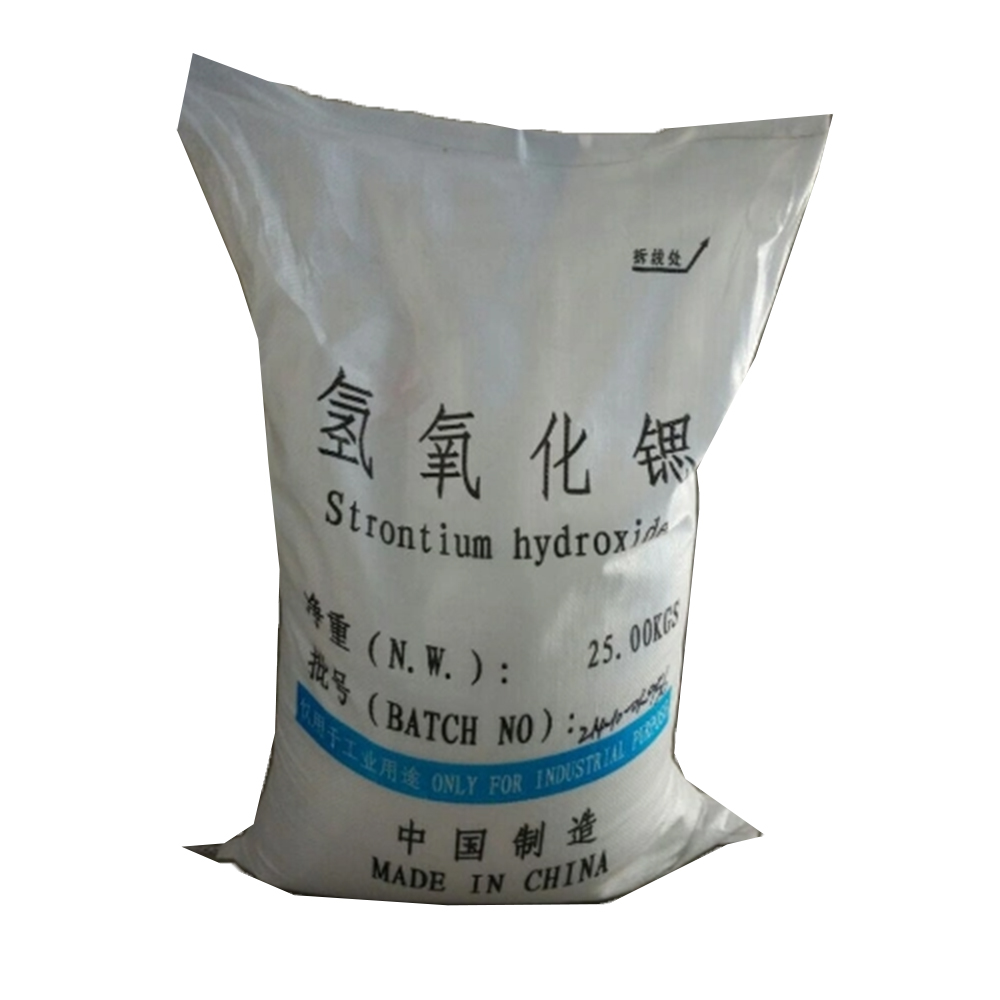

3. Storage and Packaging Liquid caustic soda is typically transported and stored in specialized containers to prevent leakage and reaction with other substances. It can be distributed in bulk or in smaller packaged forms, depending on customer requirements.

Major Manufacturers in the Industry

The liquid caustic soda manufacturing industry is dominated by several key players known for their scale, quality, and innovation. Companies such as Olin Corporation, Occidental Petroleum, and BASF are leaders in this market. These manufacturers invest heavily in research and development to enhance production processes, reduce costs, and improve environmental performance.

Moreover, regional players often help meet specific local market needs, supporting industries with customized solutions. Countries with robust chemical production capabilities, such as the United States, Germany, China, and India, are particularly influential in the global caustic soda market.

Environmental and Safety Considerations

While liquid caustic soda plays a crucial role in various applications, the manufacturing process and its end-use can pose environmental challenges. Manufacturers are increasingly focusing on sustainability, investing in technology that minimizes waste and emissions. Compliance with regulatory requirements regarding the handling and disposal of caustic soda is critical to mitigating potential impacts on ecosystems and human health.

Effective training for employees on safety protocols is also essential, as exposure to sodium hydroxide can lead to severe health risks. The industry utilizes advanced safety equipment and rigorous training programs to ensure the well-being of workers.

Conclusion

Liquid caustic soda manufacturers are integral to numerous industries, providing essential materials that support economic growth and infrastructure development. As the world continues to evolve, these manufacturers must balance the demands for production efficiency, safety, and environmental responsibility. With ongoing innovation and sustainable practices, the future of liquid caustic soda manufacturing looks promising, securing its place as a vital component of modern industry.

-

Using Potassium Nitrate for Colorants in Various ProductsNewsApr.29,2025

-

Safety Precautions When Handling Monopotassium PhosphateNewsApr.29,2025

-

Lead Oxide in Wastewater Treatment: A Powerful SolutionNewsApr.29,2025

-

Innovations in Sodium Chlorite ApplicationsNewsApr.29,2025

-

How Lead Nitrate is Used in Analytical ChemistryNewsApr.29,2025

-

Different Grades of Sodium Bisulfate: Which One Do You Need?NewsApr.29,2025

-

Sodium Chlorite vs. Other Disinfectants: A Comparative AnalysisNewsApr.14,2025