anionic polyacrylamide uses

feb . 15, 2025 00:43

Back to list

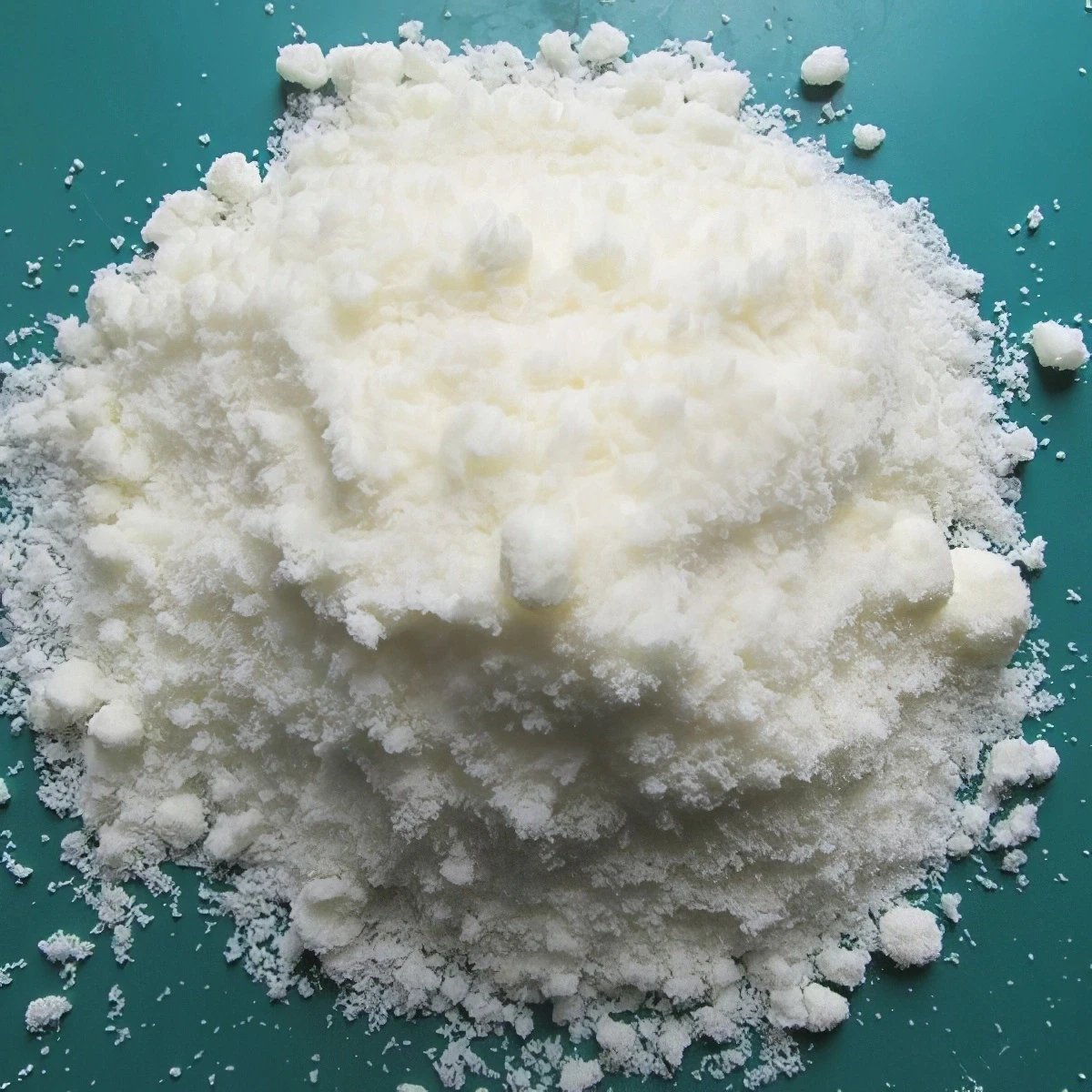

anionic polyacrylamide uses

Anionic polyacrylamide (APAM) stands as a pivotal agent in modern industrial processes. Its broad spectrum of applications is underpinned by a foundation of innovation and efficiency. A forerunner in facilitating improved performance across various sectors, APAM's unique properties make it indispensable.

In the oil industry, the importance of APAM in enhanced oil recovery (EOR) is well-documented. This application exploits the viscosity-increasing properties of APAM to improve flooding efficiency, thereby maximizing oil extraction from reservoirs. Field studies confirm that APAM-based formulations lead to enhanced recovery rates, prolonging the operational life of oil fields. Moreover, APAM's role extends to personal care products where it acts as a thickening agent, providing desirable product consistency and stability. This highlights its versatility and compliance with consumer safety requirements—a testament to the meticulous quality controls in place during its manufacture. Supported by decades of research, APAM's applications are continuously expanding, backed by scientific expertise and innovations. The reliability of APAM is evidenced by its compliance with rigorous industrial standards and certifications. As industries face rising demands for efficiency and sustainability, trust in companies supplying premium-grade APAM becomes crucial. Manufacturers of APAM, therefore, prioritize transparency and adherence to international quality benchmarks to build enduring client confidence. Research and development spearheaded by leading chemical engineers and scientists ensure that advances in APAM compositions meet emerging industrial needs while maintaining environmental integrity. Ongoing collaborations between industries and academic researchers pave the way for tailored APAM solutions, promising even greater efficacy and innovative application. In conclusion, anionic polyacrylamide's multifaceted applications catalyze advancements across a spectrum of industries. Its role in optimizing operations and ensuring environmental compliance underscores its importance in industrial processes. This synergy of efficiency, sustainability, and expertise ensures APAM remains a trusted component in the toolkit of numerous industries committed to modern innovation.

In the oil industry, the importance of APAM in enhanced oil recovery (EOR) is well-documented. This application exploits the viscosity-increasing properties of APAM to improve flooding efficiency, thereby maximizing oil extraction from reservoirs. Field studies confirm that APAM-based formulations lead to enhanced recovery rates, prolonging the operational life of oil fields. Moreover, APAM's role extends to personal care products where it acts as a thickening agent, providing desirable product consistency and stability. This highlights its versatility and compliance with consumer safety requirements—a testament to the meticulous quality controls in place during its manufacture. Supported by decades of research, APAM's applications are continuously expanding, backed by scientific expertise and innovations. The reliability of APAM is evidenced by its compliance with rigorous industrial standards and certifications. As industries face rising demands for efficiency and sustainability, trust in companies supplying premium-grade APAM becomes crucial. Manufacturers of APAM, therefore, prioritize transparency and adherence to international quality benchmarks to build enduring client confidence. Research and development spearheaded by leading chemical engineers and scientists ensure that advances in APAM compositions meet emerging industrial needs while maintaining environmental integrity. Ongoing collaborations between industries and academic researchers pave the way for tailored APAM solutions, promising even greater efficacy and innovative application. In conclusion, anionic polyacrylamide's multifaceted applications catalyze advancements across a spectrum of industries. Its role in optimizing operations and ensuring environmental compliance underscores its importance in industrial processes. This synergy of efficiency, sustainability, and expertise ensures APAM remains a trusted component in the toolkit of numerous industries committed to modern innovation.

Next:

Latest news

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025