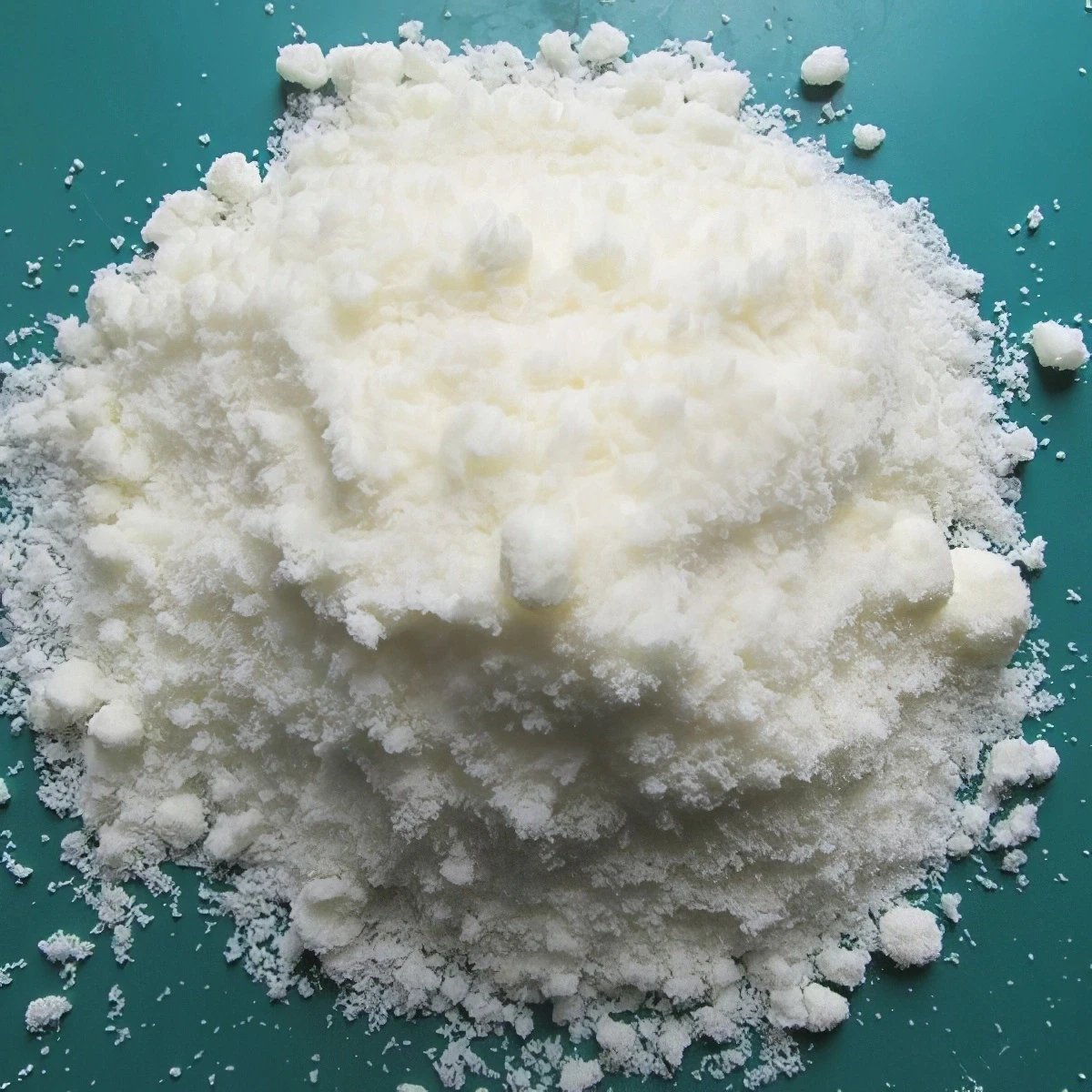

Ferric chloride &Ferric Chloride Liquid 40%

jaan. . 29, 2025 05:39

Back to list

Ferric chloride &Ferric Chloride Liquid 40%

Boiler water chemical treatment is a critical aspect of maintaining the efficiency, longevity, and overall health of industrial boiler systems. This article will provide an in-depth exploration of the innovative approaches and expert insights in this field, emphasizing real-world experiences and developments.

Moreover, pH control is a crucial element in preventing corrosion and scale. It is primarily managed by introducing neutralizing amines and alkaline compounds into the boiler water. These chemicals actively adjust the pH levels to an optimal range, maintaining system integrity and improving heat transfer effectiveness. This task requires detailed expertise and experience since the precise dosage varies with different boiler systems and operational conditions. When it comes to the trustworthiness of chemical treatment solutions, choosing a reputable supplier who complies with industry standards is imperative. Suppliers that adhere to ISO certification and provide traceability of chemical batches deliver not just products, but a promise of quality and reliability. Their expertise helps operators select the correct blend of treatments tailored to specific needs, thus safeguarding against unexpected failures. Finally, real-world experience highlights the importance of regular monitoring and testing of water samples. With IoT technologies integrating into traditional boiler systems, real-time data about water chemistry is now more accessible than ever. These advancements have enabled predictive maintenance practices, thereby identifying potential issues before they escalate. To conclude, adopting a comprehensive and sophisticated approach to boiler water chemical treatment not only enhances efficiency and prolongs the life of equipment but also contributes significantly to the operational success of industrial facilities. Leveraging cutting-edge research and domain expertise in chemical treatment, supported by credible suppliers and technologies, lays down a framework of reliability and economic advantage in the competitive industrial landscape.

Moreover, pH control is a crucial element in preventing corrosion and scale. It is primarily managed by introducing neutralizing amines and alkaline compounds into the boiler water. These chemicals actively adjust the pH levels to an optimal range, maintaining system integrity and improving heat transfer effectiveness. This task requires detailed expertise and experience since the precise dosage varies with different boiler systems and operational conditions. When it comes to the trustworthiness of chemical treatment solutions, choosing a reputable supplier who complies with industry standards is imperative. Suppliers that adhere to ISO certification and provide traceability of chemical batches deliver not just products, but a promise of quality and reliability. Their expertise helps operators select the correct blend of treatments tailored to specific needs, thus safeguarding against unexpected failures. Finally, real-world experience highlights the importance of regular monitoring and testing of water samples. With IoT technologies integrating into traditional boiler systems, real-time data about water chemistry is now more accessible than ever. These advancements have enabled predictive maintenance practices, thereby identifying potential issues before they escalate. To conclude, adopting a comprehensive and sophisticated approach to boiler water chemical treatment not only enhances efficiency and prolongs the life of equipment but also contributes significantly to the operational success of industrial facilities. Leveraging cutting-edge research and domain expertise in chemical treatment, supported by credible suppliers and technologies, lays down a framework of reliability and economic advantage in the competitive industrial landscape.

Latest news

-

Why Strontium Carbonate Still MattersNewsJun.06,2025

-

Why BaSO4 MattersNewsJun.06,2025

-

Why Barium Carbonate Still MattersNewsJun.06,2025

-

Strontium Hydroxide: A Versatile Compound for Modern ApplicationsNewsJun.06,2025

-

Strontium Chloride in Daily IndustryNewsJun.06,2025

-

Pure Potassium Nitrate for SaleNewsJun.06,2025

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025