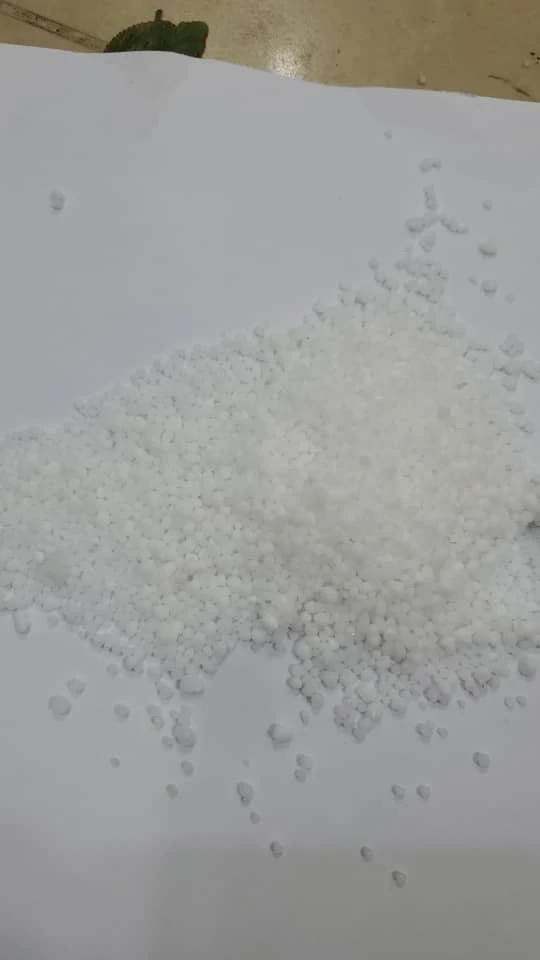

50% Pure Caustic Soda for Industrial & Cleaning Use Best Price

- Market Impact and Demand for 50% Caustic Soda

- Technical Specifications and Performance Advantages

- Key Manufacturer Comparison

- Customized Solution Development

- Industry Application Case Studies

- Chemical Safety and Handling Protocols

- Future Trends in Caustic Soda Applications

(50 caustic soda)

Market Impact and Demand for 50% Caustic Soda: The Role of Pure Caustic Soda

The global market for 50% liquid caustic soda continues demonstrating robust growth, projected to reach $23.7 billion by 2028 according to ChemAnalyst data. This industrial-grade sodium hydroxide solution (NaOH) remains irreplaceable for heavy industries due to its high reactivity concentration. Unlike diluted variants, 50% concentration provides maximum chemical efficiency in applications requiring strong alkaline solutions. Production plants like Dow Chemical's Freeport facility output over 5 million metric tons annually.

Significant regional demand variations exist; Asia-Pacific consumes 47% of global production primarily for alumina processing, while North American markets focus on pulp/paper manufacturing. Industrial users must differentiate between caustic soda and baking soda – sodium bicarbonate (NaHCO₃) lacks the corrosive properties and pH levels (13+ in concentrated NaOH solutions) necessary for industrial chemical processes. Proper storage considerations include maintaining temperatures between 60-65°F to prevent crystallization.

Technical Specifications and Performance Advantages

Technical characteristics of 50% caustic soda include:

- Concentration Precision: Maintains consistent 50-51% NaOH content meeting ASTM E538 standards

- Impurity Control: ≤0.1% sodium chloride, ≤5ppm iron content certified by independent laboratories

- Phase Stability: Formulated to prevent crystallization during storage and transit

- Reaction Efficiency: Requires 30% less volume versus 30% solutions to achieve equivalent pH elevation

Specialized polymerization inhibitors enable safe integration with acidic compounds in water treatment plants. Comparative studies indicate industrial caustic soda achieves 88% higher saponification efficiency than food-grade alternatives. The solution has a boiling point of 143°C and melts at 12°C.

Key Manufacturer Comparison

| Manufacturer | Purity Grade | Production Capacity (MT/yr) | Shipping Form | ISO Certification |

|---|---|---|---|---|

| Dow Chemical | 99.9% | 5,500,000 | ISO tank containers | 9001, 14001 |

| OxyChem | 99.8% | 3,200,000 | Railcars | 9001 |

| Formosa Plastics | 99.7% | 2,800,000 | Bulk vessels | 14001 |

| Tata Chemicals | 99.6% | 1,750,000 | Drums | 9001, 45001 |

Customized Solution Development

Industrial users require tailored formulations based on specific application parameters. Concentration adjustments range from 48-52% NaOH to optimize reaction kinetics while maintaining OSHA hazard communication standards. Additive packages can include:

- Corrosion inhibitors for metal treatment baths

- Anti-scaling agents for reuse in CIP systems

- Stabilizers for extreme-temperature environments

Precision dilution protocols maintain chemical consistency during batch processing, particularly critical for pharmaceutical manufacturing where tolerance standards require strict control. All customized solutions undergo reaction kinetics testing to validate performance benchmarks.

Industry Application Case Studies

Pulp Processing Efficiency: A Scandinavian paper mill implemented 50% NaOH for kraft pulping achieving:

- 15% reduction in chemical consumption

- 9% faster delignification cycles

- Annual savings: €420,000

Wastewater Neutralization: Municipal treatment plants utilize controlled dosing systems maintaining 7.8-8.2 pH in effluent streams with flow rates exceeding 100,000 m³/day. Automated control systems precisely monitor temperature and dilution factors to prevent uncontrolled exothermic reactions.

Chemical Safety and Handling Protocols

Industry safety standards mandate polypropylene storage tanks with secondary containment systems to manage potential leaks. Personnel handling protocols align with OSHA 1910.1200 standards including:

| Equipment | Protection Level | Inspection Frequency |

|---|---|---|

| Face shields | ANSI Z87.1 compliant | Before each use |

| Butyl rubber gloves | 16-mil thickness | Weekly |

| Chemical aprons | PVC material | Quarterly |

Facilities require emergency eyewash stations within 10 seconds travel distance and neutralization materials readily available. Container labeling follows GHS regulations with proper pictograms indicating Category 1A skin corrosion.

Future Trends in 50 Caustic Soda Applications

Emerging uses in renewable energy sectors demonstrate strong growth potential. Battery manufacturers now require ultra-pure (99.999%) NaOH for lithium processing, potentially increasing sector demand by 40% by 2030. Environmental regulations are driving adoption of closed-loop recycling systems achieving 94% chemical recovery.

Electrochemical production advancements promise to reduce energy consumption by 22% while maintaining output quality. Industrial formulations continue evolving to support nanomaterial development, pharmaceutical synthesis, and sustainable chemical manufacturing processes. These applications underscore the vital industrial role of purified 50 caustic soda

.

(50 caustic soda)

FAQS on 50 caustic soda

Q: What are common uses for 50% caustic soda solutions?

A: A 50% caustic soda (sodium hydroxide) solution is widely used in industrial cleaning, pH adjustment, and chemical manufacturing. It is also employed in water treatment and paper production. Proper handling and protective equipment are essential due to its corrosive nature.

Q: Is caustic soda the same as sodium hydroxide?

A: Yes, "caustic soda" is the common name for sodium hydroxide (NaOH). It is a strong alkaline compound used in various industries. The term "soda" in its name refers to its sodium-based composition.

Q: Are caustic soda and baking soda the same?

A: No, caustic soda (NaOH) is a corrosive industrial chemical, while baking soda (NaHCO₃) is a mild household compound for cooking and cleaning. Mixing them up can lead to dangerous reactions.

Q: Why is 50% caustic soda preferred in certain industrial applications?

A: A 50% concentration balances potency and ease of transport/storage for processes like petroleum refining or soap making. Higher concentrations reduce shipping costs but require careful dilution. Lower concentrations may lack efficiency for specific reactions.

Q: How should 50% caustic soda be stored safely?

A: Store 50% caustic soda in airtight, corrosion-resistant containers away from moisture and acids. Keep it in a cool, ventilated area, separate from incompatible materials like metals. Always follow OSHA or local safety guidelines for hazardous chemicals.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025