polyacrylamide msds

Polyacrylamide Safety Data Sheet (MSDS) Overview

Polyacrylamide is a synthetic polymer widely used in various industrial applications, including water treatment, paper manufacturing, and as a soil conditioner in agriculture. Given its extensive use, it is crucial for professionals handling this material to be aware of its safety and handling guidelines as outlined in its Material Safety Data Sheet (MSDS). This article provides an overview of the significant sections typically found in a polyacrylamide MSDS, along with safety considerations.

1. Product Identification

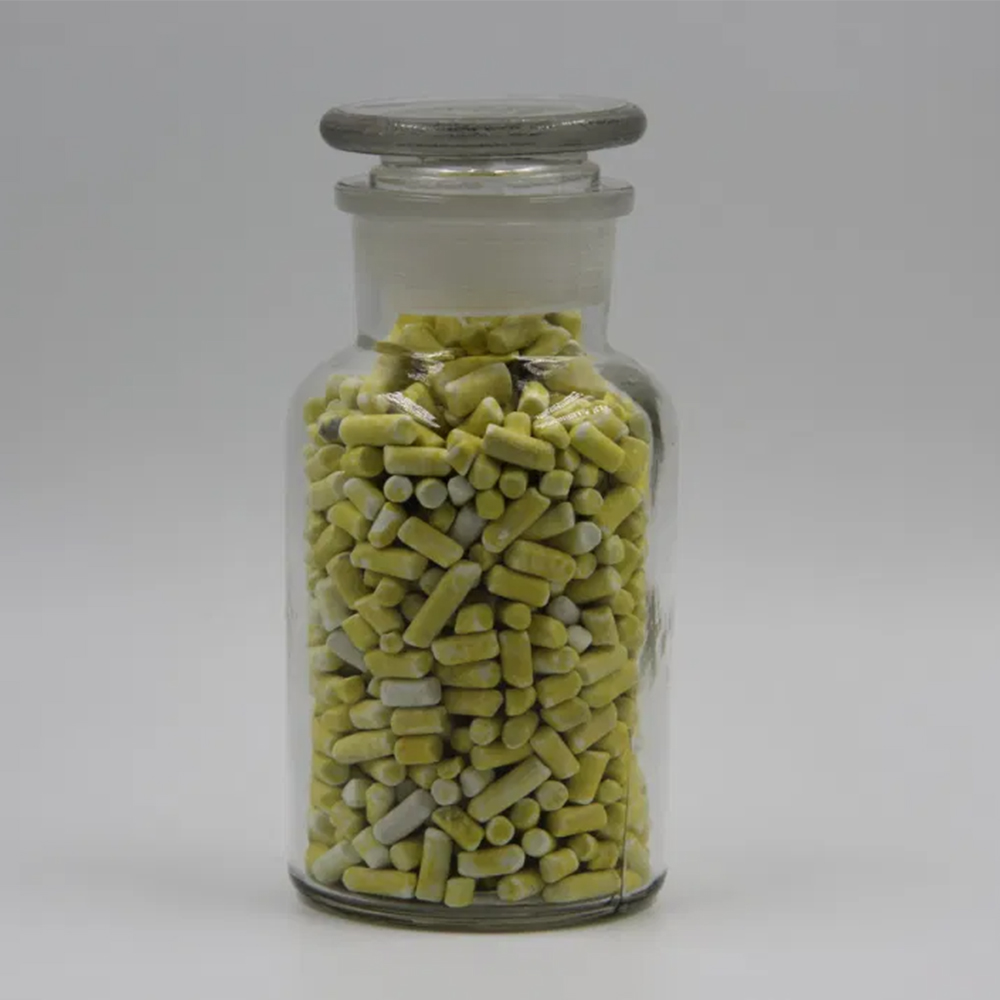

The MSDS begins with the identification of the chemical. Polyacrylamide is commonly presented in the form of a white powder or a gel, and its chemical structure is based on the polymerization of acrylamide monomers. This section includes information such as the product name, synonyms, manufacturer details, and emergency contact information.

2. Hazard Identification

The hazard identification section outlines the potential risks associated with polyacrylamide. While polyacrylamide is generally considered safe, exposure to unpolymerized acrylamide, which is a recognized health hazard, is a concern. It may pose risks such as irritation to the skin, eyes, and respiratory tract. Chronic exposure to acrylamide has been linked to neurotoxicity and potential carcinogenic effects. Therefore, proper handling and awareness of these hazards are crucial.

3. Composition and Ingredients

This section specifies the chemical composition of polyacrylamide, typically indicating that it is a polymer formed from acrylamide units. It may also note the presence of stabilizers or additives that enhance its properties or performance. Understanding the composition is crucial for assessing potential risks.

4. First Aid Measures

polyacrylamide msds

The first aid measures section provides guidance on actions to take in case of exposure. If skin contact occurs, the affected area should be washed with soap and water for at least 15 minutes. In the event of eye contact, it is advised to rinse the eyes gently with water for 15 minutes and seek medical attention. Inhalation of dust or mist may require moving the affected individual to fresh air. This section underscores the importance of prompt action to reduce health risks.

5. Fire-Fighting Measures

While polyacrylamide itself is not flammable, the MSDS includes fire-fighting measures. It suggests using water spray, foam, or dry chemical extinguishers to put out fires involving acrylamide or contaminated materials. Awareness of the correct extinguishing agents is vital for ensuring safety during potential fire incidents.

6. Handling and Storage

Proper handling and storage conditions are essential to minimize risks. The MSDS recommends storing polyacrylamide in a cool, dry place away from incompatible substances. Use personal protective equipment (PPE) such as gloves, goggles, and respiratory protection when handling the product to avoid direct exposure to skin and inhalation of fine particles.

7. Exposure Controls and Personal Protection

This section outlines the recommended exposure limits and the need for engineering controls, such as local ventilation, to minimize inhalation risks. Regular monitoring of the workplace environment is advisable to ensure compliance with safety standards.

In conclusion, understanding the contents of the polyacrylamide MSDS is crucial for ensuring safe handling and use of the material. By adhering to the safety guidelines provided, professionals can significantly reduce the risk of exposure and ensure a safer working environment. Always consult the most recent MSDS for specific details and updates regarding polyacrylamide and its health and safety information.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025