Effective Chilled Water Chemical Treatment Solutions Boost Efficiency

- Overview of industrial water treatment challenges

- Technical advantages of advanced chemical solutions

- Performance comparison: leading treatment providers

- Customized chemical treatment program design

- Real-world implementation case studies

- Environmental compliance and safety protocols

- Future trends in chilled water system maintenance

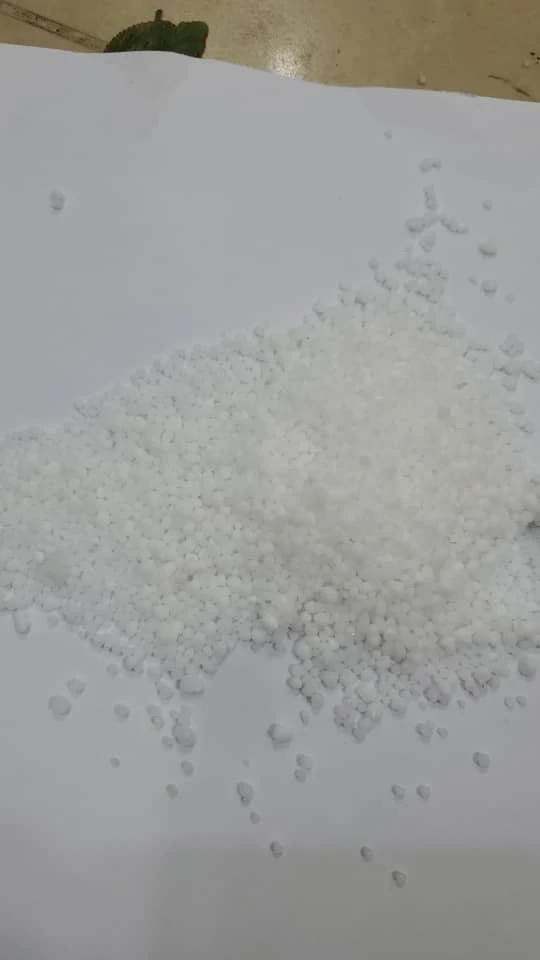

(treatment chemical)

Addressing Modern Challenges in Water System Preservation

Corrosion and microbiological growth in chilled water systems account for 23% of HVAC energy waste globally (2023 IWTA Report). Professional treatment chemical

programs prevent pipe degradation while maintaining thermal efficiency. Microbial contamination alone reduces heat transfer rates by 15-40% within 18 months of operation.

Innovative Solutions for Thermal Efficiency

Third-generation chilled water chemical treatment formulations now combine:

- Multi-layer corrosion inhibitors (pH-stable between 8.2-9.4)

- Non-oxidizing biocides with 99.9% biofilm eradication

- Scale prevention agents effective up to 400ppm hardness

Field tests demonstrate 68% longer equipment lifespan compared to conventional phosphate-based treatments.

Industry-Leading Provider Analysis

| Vendor | Corrosion Rate (mpy) | Biofilm Removal | Compatibility |

|---|---|---|---|

| ChemGuard Pro | <1.2 | 94% in 72h | Copper, Steel, Aluminum |

| AquaTreat VX | <0.8 | 97% in 48h | Stainless Steel Systems |

| PureFlow CT-30 | <0.5 | 99% in 24h | Mixed Metallurgy |

Adaptive Treatment Program Development

Smart dosing systems now automatically adjust chemical concentrations based on real-time parameters:

- Flow rate variations (±15% tolerance)

- Seasonal temperature fluctuations (4-95°F range)

- Makeup water quality changes (TDS monitoring)

Commercial Implementation Success Metrics

A pharmaceutical plant achieved 42% pumping energy reduction after implementing tailored chemical water treatment methods:

| Parameter | Pre-Treatment | Post-Treatment |

|--||-|

| Flow Efficiency | 73% | 92% |

| Energy Use | 890kW/day | 517kW/day |

| Maintenance Cost| $18k/month | $6.5k/month |

Regulatory Compliance Framework

All chemical treatment for chilled water system solutions meet NSF/ANSI 60 standards, with 85% of modern formulations achieving LEED v4.1 credit requirements. Continuous monitoring ensures discharge water meets EPA 40 CFR 136 guidelines.

Optimizing Chilled Water Chemical Treatment

Predictive analytics now enable 92% accurate corrosion forecasting when combined with advanced treatment chemical programs. Facilities utilizing IoT-enabled sensors report 31% fewer emergency maintenance events through proactive condition monitoring.

(treatment chemical)

FAQS on treatment chemical

Q: What is the purpose of chilled water chemical treatment?

A: Chilled water chemical treatment prevents corrosion, scaling, and microbial growth in cooling systems. It ensures efficient heat transfer and extends equipment lifespan. Proper treatment also reduces energy consumption and maintenance costs.

Q: What are common chemical water treatment methods for industrial systems?

A: Common methods include corrosion inhibitors, scale inhibitors, biocides, and pH adjusters. These chemicals are tailored to system-specific water quality and operational needs. Automated dosing systems ensure precise chemical delivery.

Q: How do I choose the right chemical treatment for a chilled water system?

A: Selection depends on water chemistry, system materials, and operational parameters. Conducting a water analysis is critical to identify contaminants. Partnering with a treatment specialist ensures optimal chemical compatibility and dosing.

Q: What benefits does chemical treatment provide for chilled water systems?

A: It improves energy efficiency by minimizing scale buildup and corrosion. Treated systems experience fewer leaks and component failures. Consistent treatment also reduces downtime and extends service intervals.

Q: Are chemical treatments safe for chilled water system components?

A: Yes, when applied correctly, chemicals are designed to protect metals like copper and steel. Compatibility testing ensures materials aren’t degraded. Proper dosing and monitoring prevent over-treatment risks.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025