chemical cooling tower water treatment

Chemical Cooling Tower Water Treatment A Comprehensive Overview

Cooling towers are an integral component of many industrial processes, particularly in power plants, chemical processing facilities, and HVAC systems. They are designed to dissipate heat from processes and equipment, allowing for optimal operation and energy efficiency. However, the effectiveness and longevity of cooling towers can be heavily influenced by the quality of water used within the system. To combat issues such as scale, corrosion, and biological growth, chemical water treatment is essential.

The Importance of Water Quality

Water used in cooling towers is susceptible to various contaminants, including minerals (such as calcium and magnesium), organic matter, and microorganisms. These impurities can lead to several problems

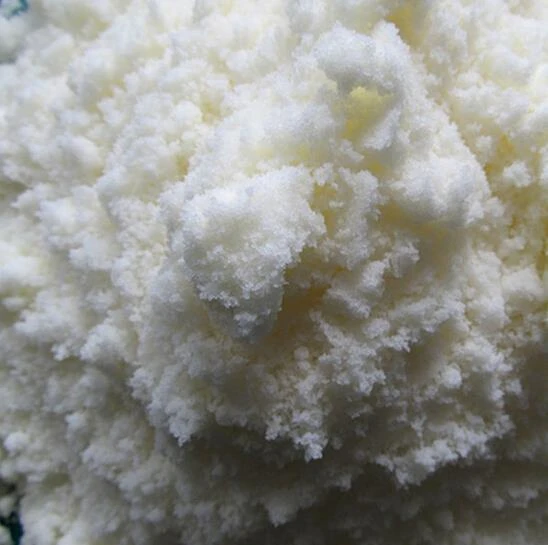

1. Scale Formation Hard water can result in the deposition of scale on heat exchange surfaces and inside the cooling tower itself. This scale acts as an insulating layer, reducing heat transfer efficiency, increasing energy consumption, and possibly causing damage to essential components.

2. Corrosion The presence of oxygen and certain ions in water can lead to corrosion of metal components, significantly reducing the lifespan of the cooling system.

3. Biological Fouling Cooling towers provide an ideal environment for algae, bacteria, and other microorganisms to thrive. Biofilm formation can obstruct water flow, reduce heat transfer efficiency, and even lead to serious health risks due to the potential spread of pathogens such as Legionella.

Chemical Treatment Methods

To maintain water quality, a variety of chemical treatments are employed, each targeting specific issues

1. Scale Inhibitors These chemicals, such as phosphonates and polyacrylates, are added to the water to prevent the formation of scale. They work by interfering with the crystallization process of minerals, making it more difficult for them to deposit on surfaces.

2. Corrosion Inhibitors Chemicals like azoles and molybdates are used to protect metal surfaces from corrosion. These compounds form a protective layer on metal surfaces, minimizing the contact between the water and the metal, thereby reducing the rate of corrosion.

3. Biocides To control biological growth, biocides such as chlorine, bromine, and non-oxidizing agents like benzalkonium chloride are applied. These chemicals help eliminate harmful microorganisms and prevent biofilm formation, ensuring the system operates efficiently and safely.

chemical cooling tower water treatment

4. pH Adjusters Maintaining the proper pH balance is critical in cooling tower operations. Chemicals such as sodium hydroxide or sulfuric acid can be added to adjust the pH, which influences the effectiveness of other treatment chemicals and helps to mitigate corrosion and scale build-up.

Monitoring and Control

Effective water treatment is not solely about adding chemicals; it also involves regular monitoring and adjustment. Parameters such as conductivity, pH, and biocide levels must be routinely checked to ensure that the cooling tower operates within optimal conditions. Automated systems equipped with sensors and control units can help in maintaining precise chemical dosages, thereby enhancing the efficiency of treatment and minimizing operational costs.

Benefits of Chemical Treatment

Implementing a robust chemical treatment program for cooling towers offers numerous benefits

- Enhanced Efficiency By preventing scale and corrosion, chemical treatments help maintain optimal heat transfer rates and energy efficiency.

- Extended Equipment Life Protecting metal surfaces from corrosion and fouling prolongs the life of cooling tower components, reducing maintenance costs and downtime.

- Improved Safety By controlling microbial growth and biofilm accumulation, chemical treatments mitigate health risks associated with cooling towers.

- Regulatory Compliance Many industries are subject to strict regulations regarding water quality and environmental impact. Chemical treatment helps meet these regulatory requirements, ensuring safe and environmentally responsible operation.

Conclusion

In conclusion, chemical cooling tower water treatment is vital for maintaining the efficiency, safety, and longevity of cooling systems. By utilizing a combination of scale inhibitors, corrosion inhibitors, biocides, and proper monitoring practices, facilities can ensure optimal performance while also adhering to regulatory standards. As industries continue to emphasize sustainability and resource efficiency, the role of effective water treatment will only become more significant in the management of cooling tower operations.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025