Understanding the Density Variations of Polyacrylamide Solutions for Various Applications

Understanding Polyacrylamide Density Applications and Implications

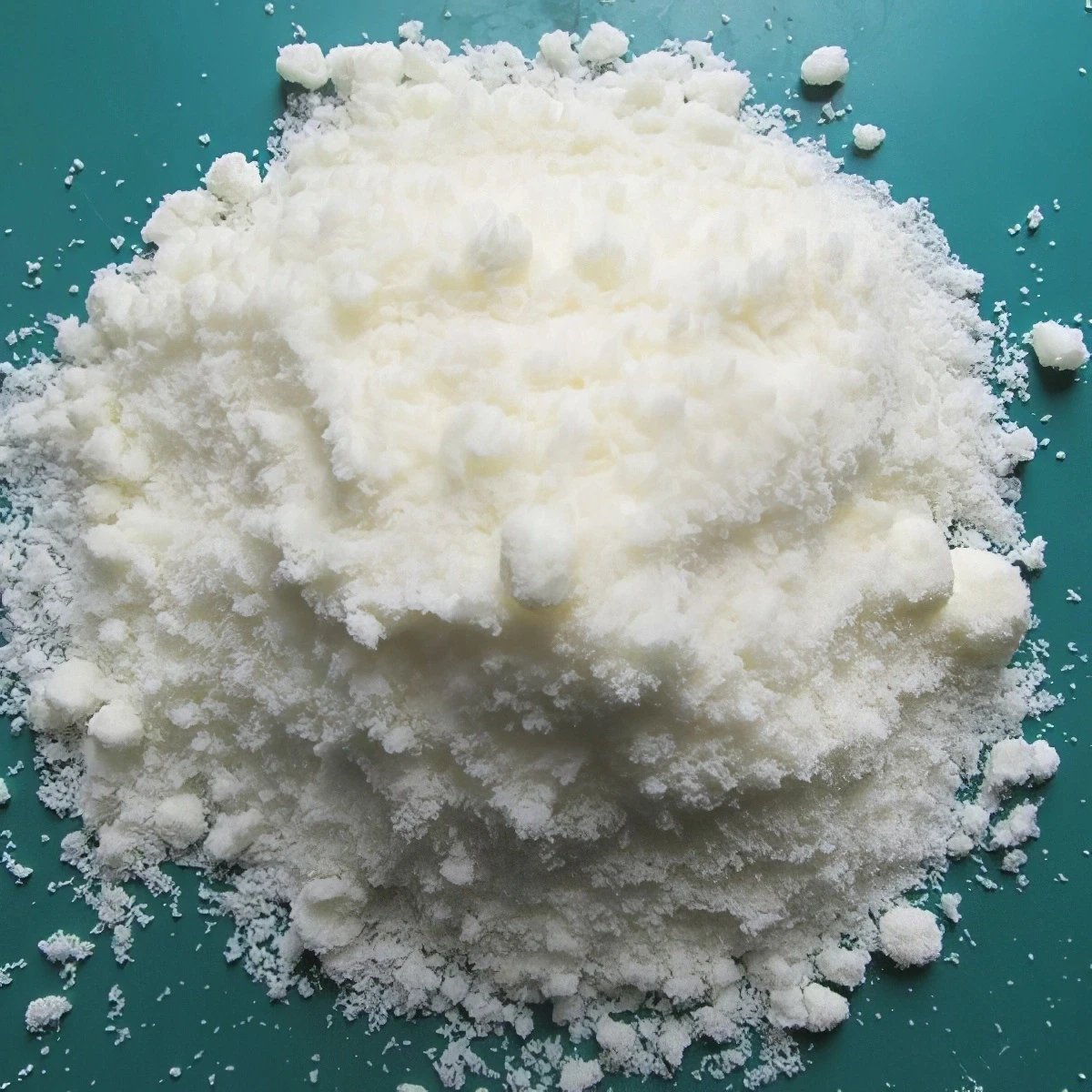

Polyacrylamide (PAM) is a versatile polymer primarily utilized in various industrial applications, including wastewater treatment, soil conditioning, and as a stabilizing agent in various chemical processes. One of the crucial physical properties of PAM is its density, which can significantly influence its behavior and effectiveness in different applications. This article delves into the importance of polyacrylamide density, factors affecting it, and its implications in practical applications.

What is Polyacrylamide?

Polyacrylamide is derived from acrylamide, a compound formed through the polymerization process. The resulting polymer can be produced in various forms, including linear and cross-linked structures, which allows for a range of functionalities. Due to its ability to retain water and enhance soil structure, polyacrylamide has become a popular choice in agriculture for soil stabilization and erosion control.

Importance of Density

Density, defined as mass per unit volume, can affect how polyacrylamide interacts with other substances in various environments. Generally, the density of polyacrylamide can range from 1.0 to 1.2 grams per cubic centimeter (g/cm³), depending on its molecular weight and degree of cross-linking. This property is crucial for understanding how the polymer behaves in suspension and its overall effectiveness for specific uses.

1. In Water Treatment In wastewater treatment plants, the density of polyacrylamide affects its settling properties during the flocculation process. Higher density PAM tends to settle faster, enhancing the separation of solid particles from the liquid waste. This quality is essential for achieving clearer effluents that meet environmental regulations.

2. Agricultural Applications When used in agriculture, the density of polyacrylamide facilitates its interaction with soil and water. A denser formulation may improve its performance in retaining moisture and improving soil aeration. This can lead to better crop yields, especially in arid regions where water conservation is critical.

polyacrylamide density

3. Oil and Gas Industry In the oil and gas sector, polyacrylamide is utilized during hydraulic fracturing and enhanced oil recovery. The density of PAM gels is vital for ensuring that they can withstand high pressures and temperatures without compromising their structural integrity.

Factors Affecting Density

Several factors can influence the density of polyacrylamide, including

- Molecular Weight Higher molecular weight PAM typically has a lower density due to the increased volume occupied by the polymer chains. This characteristic can affect its solubility and effectiveness in various applications.

- Cross-linking The degree of cross-linking in the polymer also plays a significant role in determining density. Cross-linked PAM is generally denser and can exhibit different physical properties compared to linear PAM.

- Solvent Interaction The density of polyacrylamide can change when it interacts with solvents. The extent to which it hydrates when mixed with water or other solvents influences its effective density and performance in solution.

Conclusion

Polyacrylamide's density is a critical factor in its applications across various industries. Understanding how density affects its behavior helps in optimizing its use for specific purposes like water treatment, agriculture, and oil recovery. As research continues to explore new formulations and modifications of polyacrylamide, we can expect enhanced materials that leverage this property for even greater efficacy and sustainability in industrial applications. Ultimately, by comprehensively understanding polyacrylamide density, practitioners can make informed decisions, leading to better outcomes in their respective fields.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025