Polyacrylamide Applications Efficient Water Treatment & Industrial Solutions

- Introduction to industrial polymers and key chemicals

- Technical advantages of polyacrylamide in water treatment

- Critical application areas for caustic soda and potassium nitrate

- Manufacturer performance comparison: efficiency metrics

- Customization strategies for industry-specific challenges

- Field implementation case studies

- Future perspectives in chemical applications

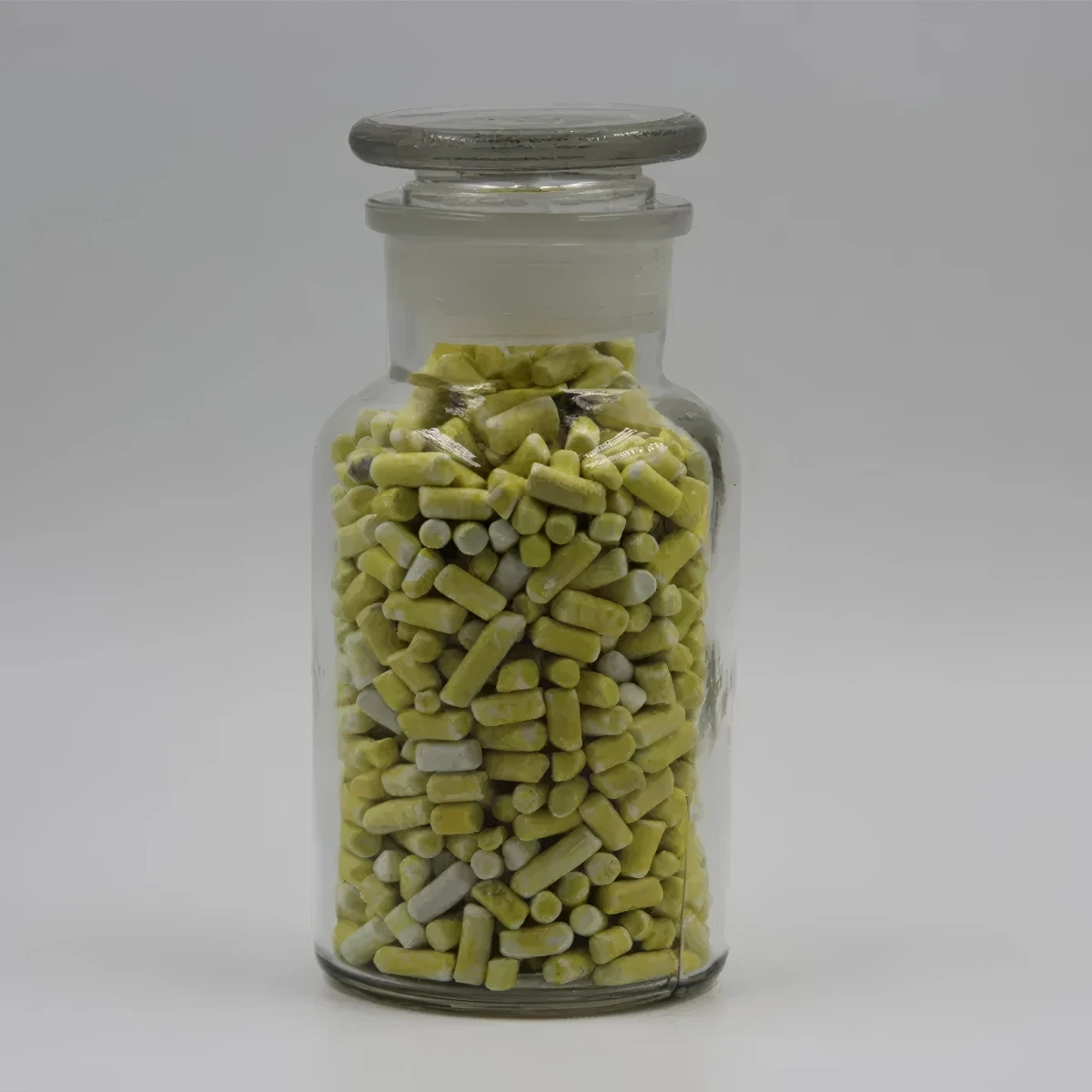

(application of polyacrylamide)

Essential Chemical Foundations for Modern Industrial Processes

Industrial operations rely heavily on specialized chemicals like polyacrylamide, caustic soda, and potassium nitrate to maintain efficiency and compliance. Polyacrylamide's unique polymer structure enables physical processes impossible with conventional chemicals, while caustic soda (sodium hydroxide) serves as the backbone for pH regulation across industries. Potassium nitrate plays dual roles in agriculture and pyrotechnics, demonstrating the versatility of these compounds. Global demand patterns reveal polyacrylamide consumption increasing at 6.2% annually, primarily driven by environmental regulations requiring advanced wastewater treatment solutions.

Performance Advantages in Water Remediation

Polyacrylamide outperforms traditional coagulants with its anionic polymer chains creating stronger flocculation bonds. Municipal water plants report 30-50% faster sedimentation rates when using optimized polyacrylamide formulations compared to aluminum sulfate alternatives. The true innovation lies in dosage efficiency - achieving comparable turbidity reduction with just 0.5-1.0 ppm versus 20-40 ppm required by mineral coagulants. This concentration advantage translates to dramatic cost savings: a 100,000 m³/day facility reduces chemical expenses by $217,000 annually while cutting sludge volume by 40%.

Complementary Chemical Applications

Caustic soda applications extend beyond pH control to critical roles in pulp processing (12% global usage) and alumina production (11% consumption). The electrochemical industry consumes 27% of global supply for mercury cell processing. Potassium nitrate solutions enable precision agriculture through controlled-release fertilization, improving crop yields by 15-25% in OECD field trials while reducing nitrate leaching. In manufacturing, potassium nitrate formulations facilitate specialized metal treatment processes requiring exact temperature thresholds between 400-550°C.

| Manufacturer | Solid Content (%) | Dissolution Time (min) | Viscosity (mPa·s) | Floc Formation Speed | pH Tolerance |

|---|---|---|---|---|---|

| SNF Flopam | 90.2 ± 0.3 | 43.2 | 2800 | 8.2 s | 4.0–10.0 |

| BASF Magnafloc | 89.8 ± 0.5 | 56.8 | 3200 | 9.7 s | 4.5–9.5 |

| Kemira Superfloc | 88.5 ± 0.6 | 62.4 | 2900 | 11.3 s | 5.0–10.0 |

| Sinofloc | 87.3 ± 0.9 | 78.5 | 2500 | 15.1 s | 6.0–9.0 |

Tailored Formulation Engineering

Custom polyacrylamide development requires molecular weight adjustments between 5–20 million Daltons and charge density modifications (±30%) to match specific contaminants. Mining operations treating tailing ponds with high clay content utilize cationic polymers achieving 97% solids recovery at 1.2 g/m³ dosage. Food processing facilities leverage low-acrylamide residual formulations meeting EFSA's 0.1 ppm threshold. Advanced delivery systems now incorporate microencapsulated potassium nitrate for agricultural applications, with release profiles calibrated to soil moisture levels and crop growth stages.

Field Validation Through Industrial Case Studies

A Chilean copper mine implemented polyacrylamide clarification technology in 2022, reducing process water turbidity from 280 NTU to 5.2 NTU while recovering 98% of process chemicals. This $2.3 million investment yielded 14-month ROI through reagent recycling. Textile manufacturers in Bangladesh integrated caustic soda recovery systems that reduced NaOH consumption by 65% annually. Dutch greenhouse operators utilizing potassium nitrate fertigation protocols demonstrated 38% yield improvement in tomato crops, with nutrient efficiency increasing from 45% to 78%.

Application Synergies and Emerging Techniques

Integrated systems combining polyacrylamide flocculation with caustic soda pH adjustment demonstrate superior heavy metal removal efficiency – cadmium elimination improves from 82% to 98% when controlling pH at 8.5 ± 0.2 before polymer addition. Biotechnology advances include enzyme-modified potassium nitrate carriers for precision agriculture. The most significant evolution emerges in automated monitoring systems: IoT sensors now regulate polyacrylamide dosage in real-time based on influent turbidity fluctuations, reducing chemical overuse by 17–22% in modern treatment facilities.

Future Projections for Chemical Applications

Advanced application of polyacrylamide

will evolve through bio-based production methods that reduce carbon footprints by 55%. Membrane technology integration will enhance caustic soda recovery efficiency beyond 92% in chlor-alkali plants. Potassium nitrate formulations are entering energy storage applications, with pilot projects demonstrating 30% cost reduction in thermal batteries. As water scarcity intensifies, polyacrylamide-based treatment solutions will become indispensable – projections indicate 75% of new municipal plants will adopt advanced polymer systems by 2030, driving innovation in sustainable application methods across the chemical industry.

(application of polyacrylamide)

FAQS on application of polyacrylamide

Q: What are the main industrial applications of polyacrylamide?

A: Polyacrylamide is primarily used as a flocculant in water treatment to remove contaminants. It also enhances oil recovery in petroleum extraction and acts as a binder in paper manufacturing. Additionally, it aids in soil conditioning for agriculture.Q: How is caustic soda utilized in chemical manufacturing?

A: Caustic soda (sodium hydroxide) is essential for producing soaps, detergents, and organic chemicals. It neutralizes acids and regulates pH in industrial processes. It’s also critical in aluminum production and petroleum refining.Q: What role does potassium nitrate play in agriculture?

A: Potassium nitrate is a key fertilizer providing nitrogen and potassium to crops. It improves drought resistance and fruit quality in plants. It’s also used in controlled-environment farming for nutrient solutions.Q: Why is polyacrylamide important in wastewater treatment?

A: Polyacrylamide binds suspended particles, enabling efficient solid-liquid separation. It reduces sludge volume and improves water clarity. This makes it vital for municipal and industrial wastewater systems.Q: How does caustic soda contribute to the paper industry?

A: Caustic soda breaks down wood pulp into cellulose fibers during paper production. It also cleans and processes recycled paper by removing inks and impurities. Its pH-adjusting properties are crucial for bleaching processes.-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025