High Quality Clay Pot Crucible for Metal Casting Durable Clay Graphite Crucible

- Introduction: Understanding the Use and Importance of Clay Pot Crucibles

- Material Composition and Advanced Features

- Technical Edge: Comparing Clay Pot Crucibles and Clay Graphite Crucibles

- Making a Clay Crucible: Essential Steps and Considerations

- Manufacturer Comparison: Performance, Price, and Supply Chain Analysis

- Tailor-Made Solutions and Industrial Applications

- Conclusion: The Future of Clay Pot Crucible and Industry Adoption

(clay pot crucible)

Introduction: The Essential Role of Clay Pot Crucible in Modern Metallurgy

Clay pot crucibles form the backbone of both traditional and advanced metal smelting processes. Their origins date back thousands of years, but modern manufacturing continues to push the boundaries of what these seemingly simple vessels can achieve.

A clay pot crucible

acts as both a durable container and a chemically inactive medium for melting ferrous and non-ferrous metals. Where high purity and resistance to thermal shock are critical, these crucibles excel. An estimated 60% of global non-ferrous metal foundries rely on clay-based crucibles due to their optimal performance at temperatures up to 1600°C (2912°F). Understanding their construction, differences with clay graphite crucibles, and production nuances offers invaluable insight to producers and users alike.

Material Composition and Advanced Features

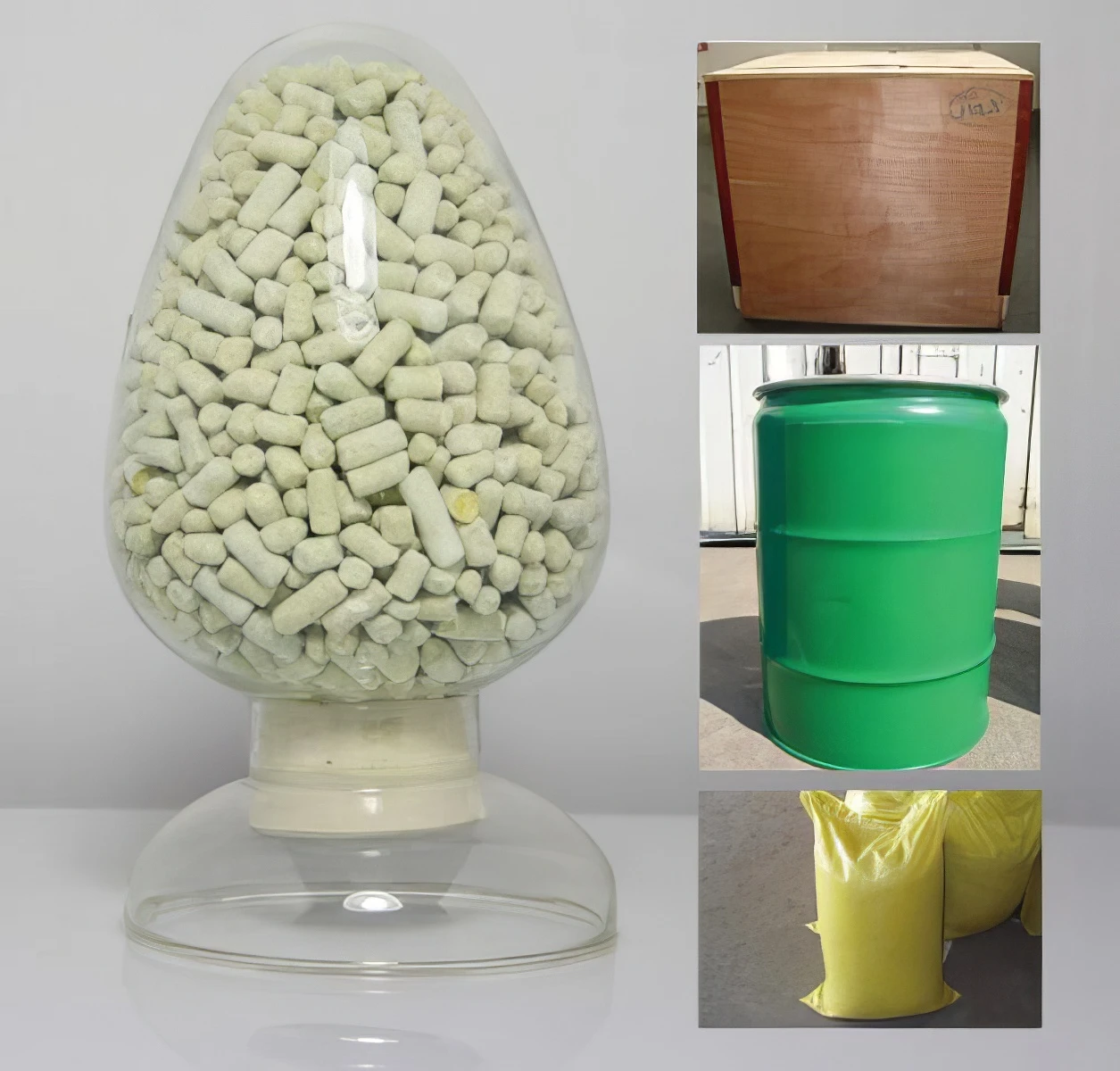

The primary value of a clay pot crucible lies in its composition. High-quality clay is blended with silica and grog (pre-fired clay aggregate) to enhance thermal resilience, mechanical strength, and minimize spalling under rapid temperature changes. Modern innovations have also led to the addition of alumina, zircon, and proprietary fluxes for enhanced corrosion resistance.

A conventional clay pot crucible contains around 70-85% refractory clay, with 10-15% silica, and a controlled moisture content below 0.5%. This composition is responsible for the vessel’s low porosity (<10%), which directly translates to longer service life and reduced risk of contamination.

Key product features include:

- Withstand thermal cycling of 10-20 times without visible degradation

- Corrosion resistance against common foundry fluxes and slag

- Uniform wall thickness for even heat distribution

- Mechanical stability under heavy metal mass

Technical Edge: Comparing Clay Pot and Clay Graphite Crucibles

Accuracy in selecting the right crucible is vital to optimizing foundry performance. While clay pot crucibles are purely refractory clay, clay graphite crucibles introduce carbon (up to 30%) for higher thermal conductivity and reduced sticking of molten metal.

The table below compares the two based on technical and operational benchmarks:

| Parameter | Clay Pot Crucible | Clay Graphite Crucible |

|---|---|---|

| Max Service Temperature | 1600°C (2912°F) | 1700°C (3092°F) |

| Thermal Shock Resistance | High | Very High |

| Life Cycles (Standard Use) | 40-60 melts | 50-80 melts |

| Average Price Range (USD, 10kg) | $45 - $55 | $70 - $90 |

| Contamination Risk | Very Low | Moderate (depends on metal) |

| Common Use | Alloy, brass, bronze, gold | Aluminum, copper, silver |

Making a Clay Crucible: Essential Steps and Considerations

The process of making a clay crucible demands precision at every stage to deliver consistent quality.

Step 1: Raw Material Selection

Fine fireclay, low in iron impurities (<0.3%), ensures reduced risk of reacting with the melt.

Step 2: Preparation and Mixing

A mixture of clay and grog is moistened and kneaded to ensure uniformity, followed by a resting period for plasticity development.

Step 3: Shaping

Crucibles are shaped either by hand-throwing on a wheel for small-scale production or using semi-automated pressing for industrial batches. Mold precision is vital to prevent weak points.

Step 4: Drying and Firing

After pre-drying at ambient temperature over 48-72 hours, the crucibles undergo staged kiln firing up to 1200°C, stabilizing the microstructure. Cooling must be gradual to prevent thermal fractures.

Modern techniques incorporate vacuum de-airing and additive manufacturing to enhance microhomogeneity, reduce wall defects, and enable complex geometries previously not feasible.

- Defect Rate for Industrial Clay Crucibles: <4%

- Economic Impact: Each additional cycle of use lowers operational costs by ~2.8%

Manufacturer Comparison: Performance, Price, and Supply Chain Analysis

A competitive foundry marketplace yields marked differences among crucible manufacturers. Consider the following comparative table, built from global supply chain analysis:

| Manufacturer | Annual Output (units) | Lead Time (weeks) | Product Consistency (%) | Warranty (/melt cycles) | Custom Solution Availability | Typical Export Regions |

|---|---|---|---|---|---|---|

| FerroFoundry | 600,000 | 8 | 97.8 | 65 | Yes | NA, EU |

| ThermaClay | 420,000 | 11 | 99.4 | 70 | Yes | APAC, EU |

| Global Crucible Co. | 770,000 | 6 | 96.1 | 60 | No | NA, SA |

| SmeltRite | 330,000 | 9 | 97.5 | 68 | Yes | ME, EU |

Tailor-Made Solutions and Industrial Applications

The evolution of the clay pot crucible is synonymous with the demand for tailored foundry solutions. Modern manufacturers offer comprehensive customization: size optimization for ladle integration, alteration of wall thickness for specific heating cycles, and surface treatment for flux resistance.

Notable application cases:

- Precision Jewelry Casting: Custom 1kg and 5kg crucibles engineered for gold and platinum, certified to reduce precious metal loss below 0.2% per cycle.

- Laboratory Metal Analysis: Micro-scale crucibles with internal surface coatings, improving repeatability in chemical analysis across >200 cycles.

- Specialized Alloy Production: Alumina-infused clay crucibles used to produce high-performance aerospace alloys, reporting zero contamination in controlled trials.

- Foundry Automation: RFID-enabled crucibles for lifecycle tracking—data shows a 13% reduction in inventory loss for adopters.

Conclusion: Clay Pot Crucible and Its Transformational Impact

The journey of the clay pot crucible from artisanal craft to high-tech foundry asset echoes the broader industrial transition towards precision and accountability. High-performance clay crucibles drive value not only through their material properties but through the cascading effect on operational uptime and product quality.

Emerging trends, such as AI-powered defect detection in production and integrated IoT monitoring, suggest that the next evolutionary leap will amplify both lifecycle efficiency and safety standards. As foundries worldwide continue their shift towards cost-effective and sustainable practices, the clay pot crucible is set to remain a solution at the heart of the metals value chain, empowering innovation across material science and engineering fields.

(clay pot crucible)

FAQS on clay pot crucible

Q: What is a clay pot crucible used for?

A: A clay pot crucible is generally used for melting metals and other materials at high temperatures. It can withstand intense heat without cracking or breaking. They're popular in metalworking and jewelry making.

Q: How does a clay graphite crucible differ from a standard clay crucible?

A: A clay graphite crucible includes graphite in its composition, making it more durable and conducting heat better than pure clay. This allows for higher melting temperatures and longevity. They're preferred for industrial metal melting.

Q: What materials are needed for making a clay crucible at home?

A: You typically need clay, sand, and sometimes grog or graphite for extra strength. The mixture is shaped into a pot and then fired in a kiln or furnace. This process creates a heat-resistant container for melting metals.

Q: Can you reuse a clay pot crucible?

A: Yes, as long as the crucible has not cracked or deteriorated, it can be reused. However, repeated use and thermal shock may eventually weaken the clay. Always inspect for damage before each use.

Q: What metals can be melted in a clay graphite crucible?

A: Clay graphite crucibles can handle a range of metals such as gold, silver, copper, aluminum, and brass. Their higher thermal tolerance makes them ideal for these applications. Always check the maximum temperature rating of your crucible before use.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025