Polyacrylamide

កុម្ភៈ . 15, 2025 06:24

Back to list

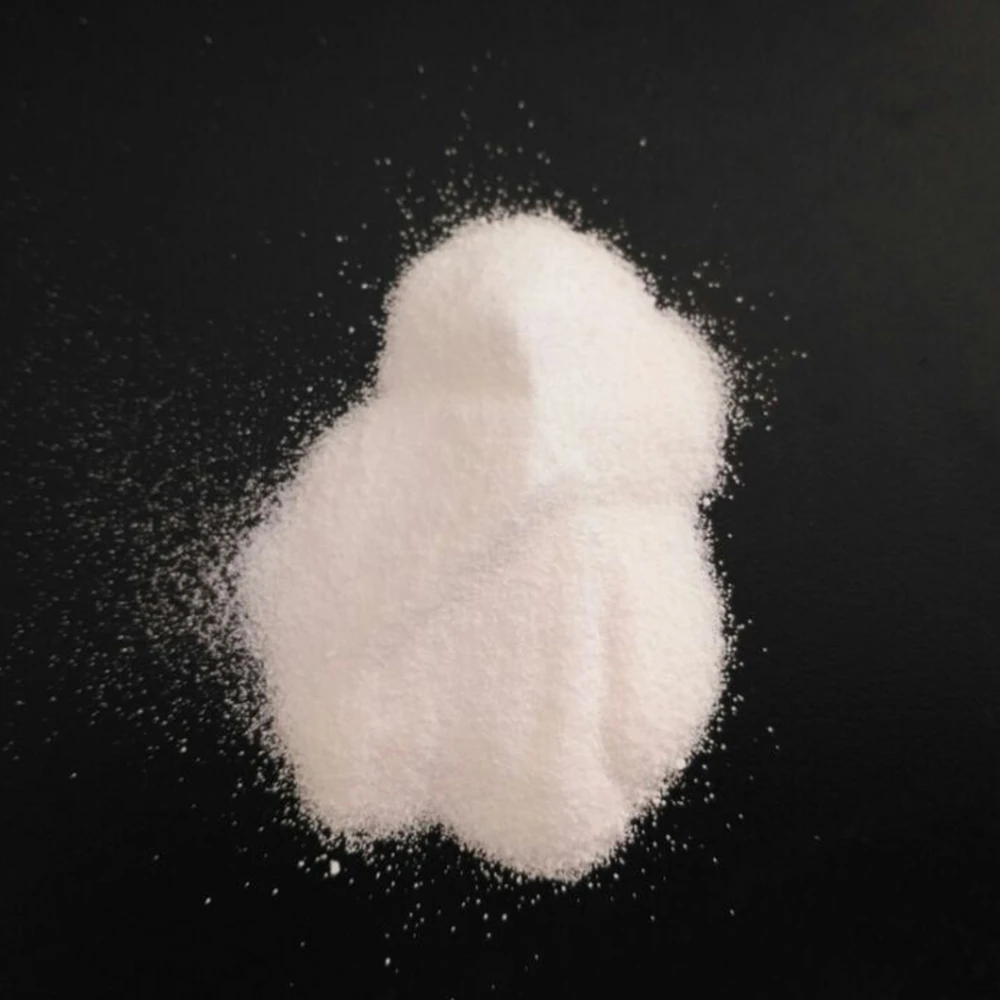

Polyacrylamide

Exploring the Versatility of Cationic PAM in Industrial Applications

Beyond these industries, cationic PAM is also integral in the realm of oil recovery. The Enhanced Oil Recovery (EOR) techniques benefit greatly from its ability to alter the viscosity of the flooding water, improving the sweep efficiency of oil reservoirs. By effectively reducing the mobility ratio, cationic PAM helps in pushing more oil towards the production wells, thus maximizing crude oil extraction. Petroleum engineers leverage comprehensive geological data alongside precise chemical formulations to deploy cationic PAM, ensuring optimal field performance. The mining industry employs cationic PAM to enhance mineral settling and clarification processes. Its flocculating properties improve solid-liquid separation, enabling the recovery of valuable minerals while minimizing water waste. Mining engineers must exhibit both expertise and trustworthiness in handling PAM, as any mishandling could lead to environmental repercussions and regulatory compliance issues. While cationic PAM offers numerous advantages, its application requires careful consideration of environmental and safety standards. Handling and storage guidelines must be strictly followed to prevent polymer degradation and potential hazards associated with its usage. Experts in chemical management must collaborate with environmental scientists to ensure that the deployment of cationic PAM aligns with sustainable development goals. To sum up, cationic PAM is a versatile polymer with diverse applications across various industries. Its ability to improve efficiency and productivity is matched by the need for profound knowledge and expertise in its application. Industries must adopt a strategic approach in using cationic PAM, one that considers environmental sustainability alongside industrial efficacy. Moreover, consistent research and development can lead to innovative applications of this compound, paving the way for future advancements in industrial processing with cationic PAM at its core.

Beyond these industries, cationic PAM is also integral in the realm of oil recovery. The Enhanced Oil Recovery (EOR) techniques benefit greatly from its ability to alter the viscosity of the flooding water, improving the sweep efficiency of oil reservoirs. By effectively reducing the mobility ratio, cationic PAM helps in pushing more oil towards the production wells, thus maximizing crude oil extraction. Petroleum engineers leverage comprehensive geological data alongside precise chemical formulations to deploy cationic PAM, ensuring optimal field performance. The mining industry employs cationic PAM to enhance mineral settling and clarification processes. Its flocculating properties improve solid-liquid separation, enabling the recovery of valuable minerals while minimizing water waste. Mining engineers must exhibit both expertise and trustworthiness in handling PAM, as any mishandling could lead to environmental repercussions and regulatory compliance issues. While cationic PAM offers numerous advantages, its application requires careful consideration of environmental and safety standards. Handling and storage guidelines must be strictly followed to prevent polymer degradation and potential hazards associated with its usage. Experts in chemical management must collaborate with environmental scientists to ensure that the deployment of cationic PAM aligns with sustainable development goals. To sum up, cationic PAM is a versatile polymer with diverse applications across various industries. Its ability to improve efficiency and productivity is matched by the need for profound knowledge and expertise in its application. Industries must adopt a strategic approach in using cationic PAM, one that considers environmental sustainability alongside industrial efficacy. Moreover, consistent research and development can lead to innovative applications of this compound, paving the way for future advancements in industrial processing with cationic PAM at its core.

Prev:

Next:

Latest news

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025