Chemicals for Effective Water Treatment in Cooling Towers and Their Benefits

Cooling Tower Water Treatment Chemicals Ensuring Efficiency and Longevity

Cooling towers play a vital role in various industrial processes, helping to dissipate heat and maintain optimal operating temperatures. However, to operate effectively and economically, these systems require proper water treatment. This is where cooling tower water treatment chemicals come into play. These specialized chemicals are essential for controlling scale, corrosion, and biological growth, ensuring that cooling towers function at peak efficiency while extending their lifespan.

The Importance of Water Treatment in Cooling Towers

Water used in cooling towers can be prone to issues such as scaling, corrosion, and biological fouling. Scaling occurs when dissolved minerals precipitate out of water, forming hard deposits that can clog pipes and impede water flow. Corrosion, on the other hand, results from chemical reactions between water and the metal components of the cooling system, leading to rust and structural damage. Moreover, biological fouling is caused by the growth of algae, bacteria, and other microorganisms, which can lead to unpleasant odors and reduced heat transfer efficiency.

To combat these challenges, it is essential to implement a comprehensive water treatment program that incorporates the right chemicals designed to address these specific issues.

Key Chemicals Used in Cooling Tower Water Treatment

1. Biocides These chemicals are formulated to control the growth of algae, bacteria, and other microorganisms within the cooling tower. Common biocides include chlorine, bromine, and non-oxidizing biocides like isothiazolinones and quaternary ammonium compounds. Effective biocide use not only helps maintain water quality but also minimizes the risk of Legionnaires’ disease, which can be spread through aerosols from cooling towers.

2. Corrosion Inhibitors These chemicals create a protective film on the metal surfaces within the cooling system, reducing the direct contact of water with metals and preventing corrosion. For example, chromates, molybdates, and phosphonates are commonly used corrosion inhibitors that help protect systems made of steel or copper from deterioration, thereby prolonging their lifespan.

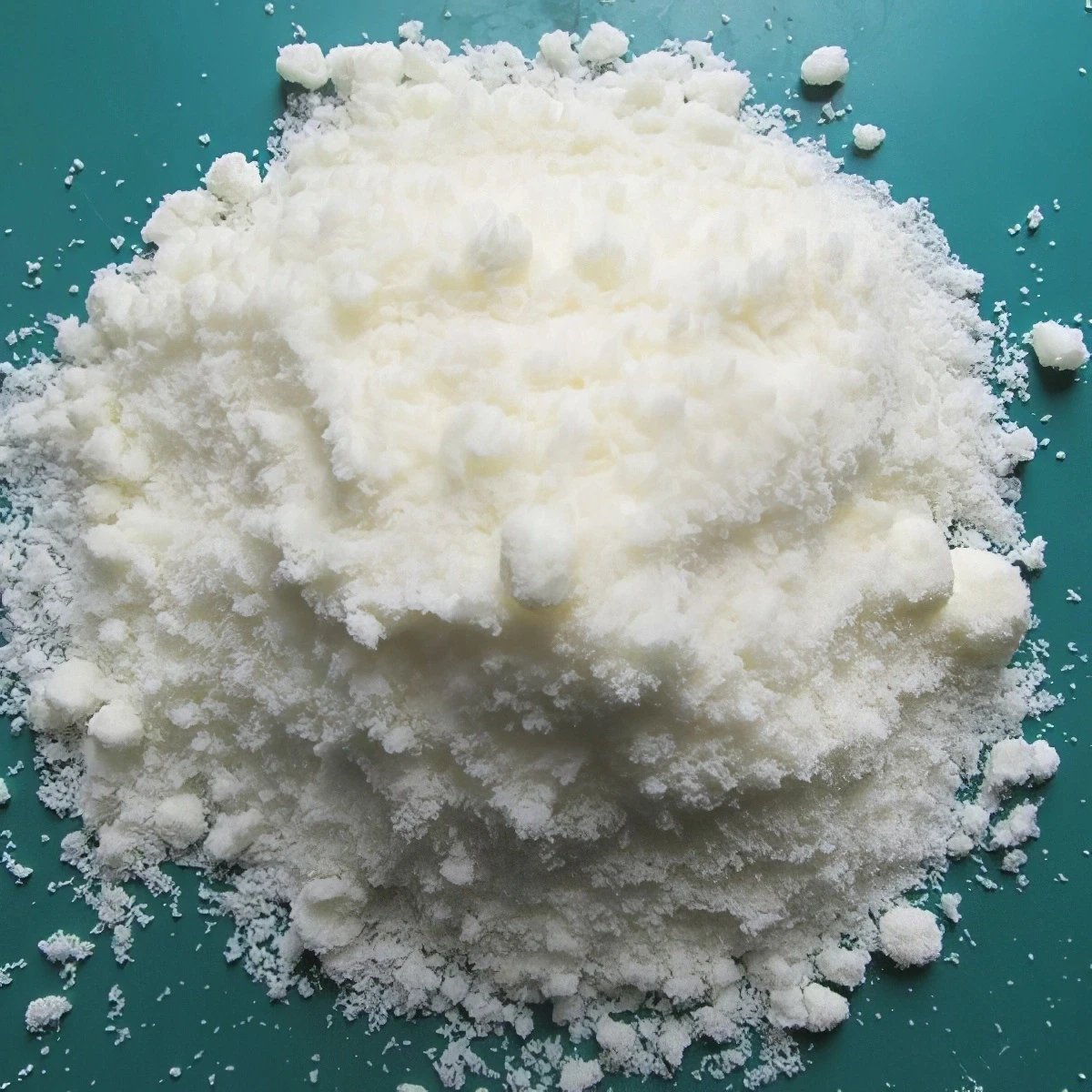

cooling tower water treatment chemicals

3. Scale Inhibitors To prevent mineral deposits from forming on heat exchange surfaces, scale inhibitors are added to the water. These chemicals, including polyacrylic acid and phosphonates, work by sequestering minerals such as calcium and magnesium, reducing their tendency to precipitate and form hard scales. Keeping the system free from scale buildup is crucial, as it ensures optimal heat transfer and reduces energy consumption.

4. pH Adjusters Maintaining the proper pH level of the cooling tower water is essential for the overall effectiveness of the water treatment program. pH adjusters, such as sulfuric acid and sodium hydroxide, are utilized to balance acidity and alkalinity, creating a more hospitable environment for biocides and corrosion inhibitors to perform effectively.

5. Flocculants In some cases, suspended particles can affect water clarity and contribute to fouling. Flocculants are added to help aggregate these particles, making it easier for them to be removed through sedimentation or microfiltration processes. This not only improves water clarity but also enhances the efficiency of biocides and other chemicals.

Implementing an Effective Water Treatment Program

To develop a successful cooling tower water treatment program, facility managers should start by conducting a thorough analysis of their water supply and the specific needs of their cooling system. This includes monitoring the water quality parameters, such as pH, conductivity, and biological content, to determine the appropriate treatment chemicals and dosages.

Regular maintenance and monitoring are also crucial. This not only involves routine chemical testing but also regular cleaning and inspection of the cooling tower system. Automated monitoring systems can significantly enhance the efficiency of the treatment process, ensuring that appropriate chemical dosages are maintained continuously.

Conclusion

Cooling tower water treatment chemicals are an essential component of maintaining the efficiency and longevity of cooling tower systems. By utilizing a combination of biocides, corrosion inhibitors, scale inhibitors, pH adjusters, and flocculants, facility managers can effectively tackle the challenges posed by scale, corrosion, and biological fouling. Implementing a well-designed water treatment program not only leads to significant cost savings but also enhances system performance, contributing to overall operational excellence in industrial settings.

-

Best Chemicals Used to Disinfect Water – Comprehensive Guide & SolutionsNewsNov.19,2025

-

Comprehensive Guide to Chemical Disinfection of Water | Safe & Sustainable SolutionsNewsNov.18,2025

-

Bleach for Sanitizing Water – A Comprehensive Guide to Safe Water Treatment SolutionsNewsNov.18,2025

-

What Is Disinfectant Water? Uses, Benefits & Future Trends ExplainedNewsNov.18,2025

-

Comprehensive Guide to Chemicals That Disinfect Water for Global Safety and IndustryNewsNov.17,2025

-

Essential Chemicals Used for Disinfection of Water: Applications, Benefits & InnovationsNewsNov.15,2025

-

Comprehensive Guide on Chemicals to Disinfect Water: Uses, Benefits & TrendsNewsNov.15,2025