industrial manufacture of sodium hydroxide

Industrial Manufacture of Sodium Hydroxide

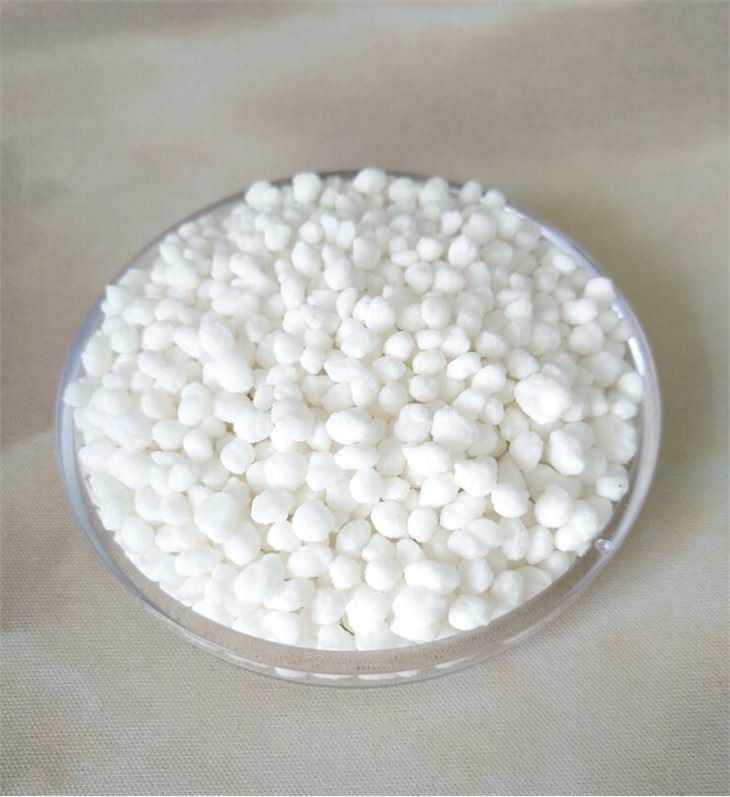

Sodium hydroxide, commonly known as caustic soda, is a highly sought-after chemical that plays a critical role across numerous industries. With applications ranging from the production of paper and textiles to food processing and water treatment, its importance cannot be understated. The industrial manufacture of sodium hydroxide is a significant process that employs several methods, each with its own advantages and challenges.

One of the primary methods used for the industrial production of sodium hydroxide is the electrolysis of sodium chloride (NaCl) solution, also known as brine. This method is crucial because it not only produces sodium hydroxide but also generates chlorine gas and hydrogen gas as by-products. The process typically takes place in an electrolytic cell, where a direct electric current is passed through the brine solution.

In the electrolysis process, when electric current flows through the cell, sodium ions (Na⁺) are attracted to the cathode where they gain electrons and are reduced to form sodium metal. However, in the typical industrial setup, the sodium immediately reacts with water to produce sodium hydroxide and hydrogen gas. Concurrently, chloride ions (Cl⁻) move to the anode, where they are oxidized to form chlorine gas. The overall reaction can be summarized as follows

\[ \text{2NaCl + 2H2O} \rightarrow \text{2NaOH + Cl2 + H2} \]

This chloralkali process is one of the most common methods for sodium hydroxide production today, primarily due to its efficiency and the relatively low cost of raw materials. Modern plants use advanced membrane cell technology, which allows for the separation of products, minimizing chlorine and hydrogen contamination in the sodium hydroxide produced.

industrial manufacture of sodium hydroxide

Another method for producing sodium hydroxide is the lime soda process, where calcium hydroxide (slaked lime) reacts with sodium carbonate (soda ash) to produce sodium hydroxide and calcium carbonate as a by-product. Although this reaction is less common in large scales due to the lower production rates compared to the chloralkali process, it is still used in some niche applications.

The direct synthesis of sodium hydroxide from elemental sodium and water is another method, but it is rarely pursued on an industrial scale due to the high reactivity of sodium and the associated safety hazards. Handling elemental sodium requires stringent safety measures, which can complicate its industrial use.

Sodium hydroxide is produced in various concentrations depending on the intended application. For instance, a concentrated solution (50-60% NaOH) is often used in industrial applications, while less concentrated solutions (around 10-20% NaOH) may find use in food processing and household cleaning products.

Despite its widespread applications, the manufacture of sodium hydroxide poses several environmental and safety challenges. The production process emits gases (chlorine and hydrogen) that must be managed to prevent environmental pollution and ensure worker safety. Additionally, the handling and storage of sodium hydroxide require special equipment and materials due to its corrosive nature, which necessitates strict adherence to safety protocols.

In recent years, there has been a growing emphasis on sustainability in chemical manufacturing, including sodium hydroxide production. Efforts to reduce energy consumption during the electrolysis process or to utilize renewable energy sources are being explored. Moreover, improvements in recycling by-products—the chlorine and hydrogen gases produced—are gaining traction, focusing on converting waste into valuable products, thus fostering a circular economy.

In conclusion, the industrial manufacture of sodium hydroxide is a vital process driven by the demands of various sectors. The chloralkali process remains the predominant method of production due to its efficiency, while ongoing innovations aim to address environmental concerns and improve sustainability. As industries continue to evolve, the focus on safer and greener production methodologies will shape the future of sodium hydroxide manufacturing, ensuring that this essential chemical continues to meet societal needs responsibly.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025