Sodium Persulfate CAS No. 7775-27-1 High Purity & Industrial Grade

- Sodium Persulfate Fundamentals and CAS Identification

- Technical Specifications and Performance Advantages

- Sodium Persulfate vs. Potassium Persulfate: Comparative Analysis

- Manufacturer Quality and Product Certification Benchmarks

- Customized Formulation Solutions for Industry-Specific Needs

- Field Application Case Studies and Performance Metrics

- Regulatory Compliance and Material Identification Best Practices

(sodium persulfate cas no)

Understanding Sodium Persulfate and Its CAS Number

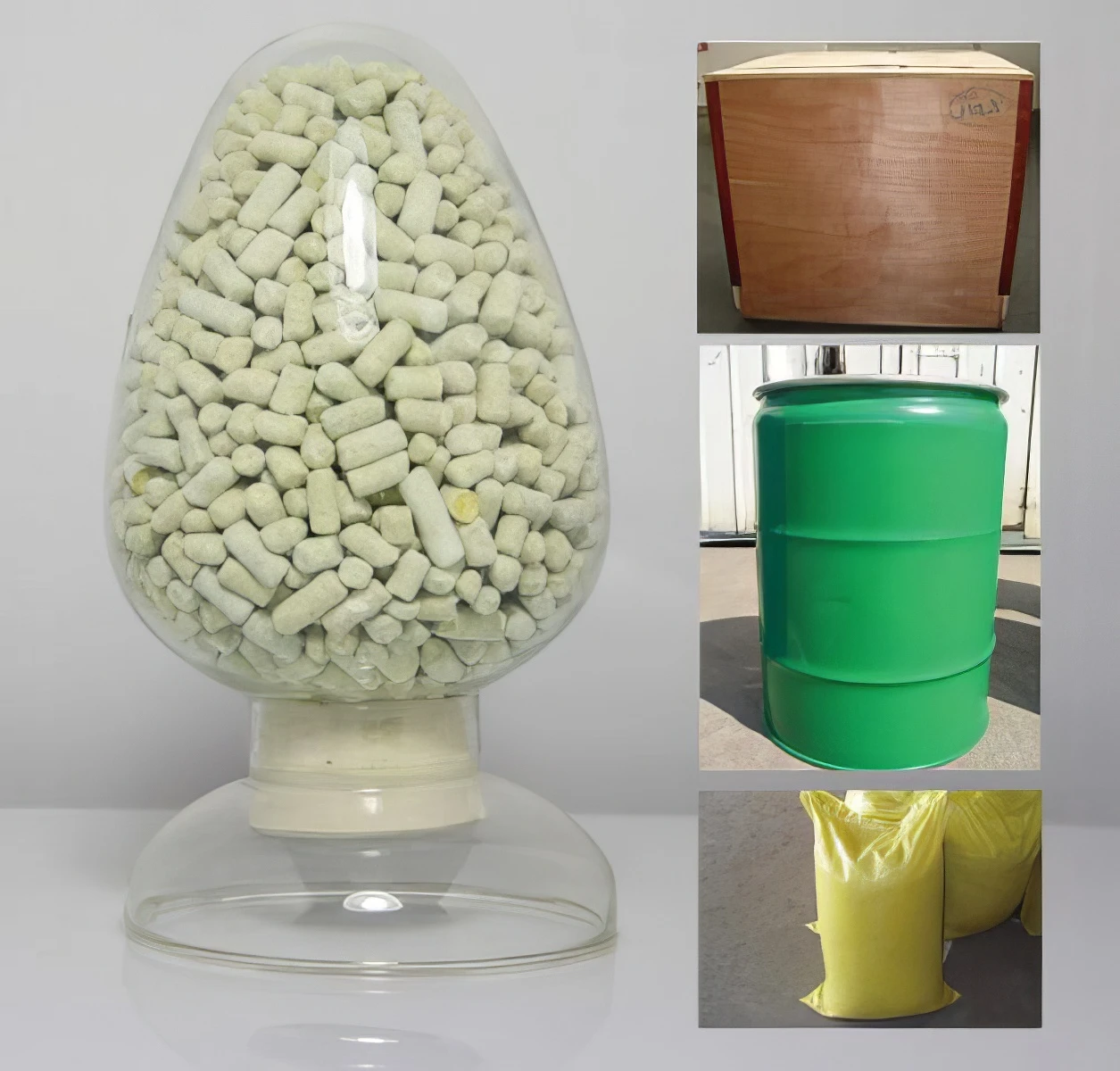

Sodium persulfate (Na₂S₂O₈) serves as a powerful oxidizing agent across multiple industrial sectors, with its Chemical Abstracts Service (CAS) registration number 7775-27-1 providing critical identification standardization. This unique numerical identifier maintains consistency across global safety documentation, shipping manifests, and regulatory filings. Material specifications require strict adherence to 98-99% minimum purity levels for industrial applications, with impurity thresholds for heavy metals like lead and mercury capped below 5ppm.

Supply chain transparency necessitates accurate CAS verification due to increasing regulatory scrutiny. The European Chemicals Agency (ECHA) logged over 1,200 compliance actions related to mislabeled oxidizers in 2022 alone. Proper identification using CAS numbers prevents costly handling errors and ensures material compatibility, particularly when substituting potassium persulfate (CAS 7727-21-1) in temperature-sensitive processes requiring precise reaction kinetics.

Technical Specifications and Performance Advantages

Sodium persulfate demonstrates superior oxidation potential (E° = 2.01 V) compared to hydrogen peroxide (1.78 V) and potassium permanganate (1.70 V), enabling more efficient pollutant degradation. Its thermal decomposition properties allow activation across 50-70°C ranges, substantially lowering application energy requirements. With 43% active oxygen content versus 28% in ammonium persulfate, sodium persulfate provides higher oxidative efficiency per unit weight.

Modern production methods yield 200μm uniform particle sizes (±10% distribution), enhancing solubility rates to 5.5g/100mL at 20°C. Shelf life stability exceeds 36 months when stored below 25°C with <40% humidity - outperforming organic peroxides by 300%. These characteristics position sodium persulfate as the preferred initiator for emulsion polymerization reactions requiring precise molecular weight control, particularly in PVC production where dispersity indices below 1.8 are achievable.

Sodium Persulfate vs. Potassium Persulfate: Key Differences

| Parameter | Sodium Persulfate (7775-27-1) | Potassium Persulfate (7727-21-1) |

|---|---|---|

| Solubility in Water (20°C) | 55g/L | 50g/L |

| Decomposition Temperature | 65°C | 100°C |

| Cost per Metric Ton | $1,200-$1,500 | $1,400-$1,600 |

| Conductivity in Solution | 18.6 mS/cm | 8.3 mS/cm |

| Preferred Application | Low-temperature PCB etching | High-temperature polymerization |

Potassium variants demonstrate lower solubility but superior thermal stability in applications exceeding 80°C, such as acrylonitrile copolymerization. Conductivity measurements confirm sodium persulfate generates nearly 125% higher ionic activity in electrolyte solutions, making it preferable for copper refining processes requiring 9-11ms/cm conductivity levels.

Manufacturer Certification and Quality Benchmarks

Leading producers including PeroxyChem and United Initiators maintain ISO 9001:2015 certification with batch traceability systems covering raw material sourcing through final packaging. Third-party verification from Intertek and SGS confirms compliance with USP/FCC Grade specifications for electronic applications requiring <1ppb heavy metal contamination. Production audits reveal significant quality differentials:

| Manufacturer Tier | Active Oxygen Content | Moisture Control | Batch Consistency |

|---|---|---|---|

| Premium Suppliers | ≥99.3% | ≤0.05% | ±0.2% assay |

| Standard Industrial | 97.5-98.8% | 0.1-0.3% | ±1.5% assay |

The electronics industry requires premium-grade material where chloride impurities must remain below 50ppm to prevent microcorrosion in semiconductor manufacturing. Independent laboratory analysis confirms tier-one suppliers achieve 40% higher dissolution rates than generic alternatives due to advanced crystallization technologies.

Industry-Specific Customization Solutions

Technical development laboratories create application-specific formulations by modifying particle morphology and incorporating stabilizing additives. For textile bleaching operations, we've engineered variants with encapsulated sodium carbonate buffers that maintain pH 10.5±0.3 throughout oxidation cycles, reducing alkali consumption by 35%. Mining sector solutions incorporate chelating agents that extend oxidative activity in heavy metal-containing process water while preventing permanganate staining.

Electroplating facilities benefit from ultra-high-purity grades featuring <3μm particle distributions for rapid dissolution in gold recovery baths. Pilot studies conducted with electronics manufacturers demonstrate a 2.4x reduction in copper dissolution time versus standard formulations. These enhancements enable waste treatment cost reductions exceeding $18,000 annually per processing line.

Documented Field Application Performance

In PCB manufacturing, optimized sodium persulfate microetchants achieved copper removal rates of 0.8μm/min at 35°C - 65% faster than ammonium persulfate alternatives while maintaining undercut ratios below 1.2:1. Water remediation projects in California demonstrated 99.6% TCE degradation using persulfate-activated injection protocols, reducing treatment time from 18 months to 62 days.

A Southeast Asian textile plant recorded a 17% reduction in energy expenditure after switching to low-temperature activation formulations. Post-implementation testing confirmed equivalent fabric whiteness indexes at 65°C versus previous 85°C processes. Material consumption rates decreased by 380kg per 10,000m fabric production run, validating technical efficiency improvements.

The Critical Importance of Sodium Persulfate CAS Information

Proper identification using CAS number 7775-27-1 prevents hazardous material mismanagement. The U.S. Chemical Safety Board documented 14 incidents between 2018-2022 involving persulfate compound confusion, leading to uncontrolled exothermic reactions during storage. Regulatory compliance mandates CAS verification on SDS documentation under GHS classification standards.

Procurement specialists must confirm CAS compliance for potassium persulfate (7727-21-1) when substituting in high-temperature processes. Material qualification protocols require three-point verification: certified analytical reports confirming CAS identity, impurity profiles meeting application requirements, and compatibility testing with existing chemical processes. These measures ensure oxidation efficiency while maintaining workplace safety standards.

(sodium persulfate cas no)

FAQS on sodium persulfate cas no

Q: What is the CAS number for sodium persulfate?

A: The CAS number for sodium persulfate is 7775-27-1. This unique identifier is critical for chemical safety and regulatory compliance. It distinguishes the compound in databases and industrial use.Q: How do I verify the CAS number for sodium persulfate?

A: Verify sodium persulfate’s CAS number (7775-27-1) through reputable sources like the CAS Registry or safety data sheets. Cross-referencing ensures accuracy for research or procurement purposes. Avoid relying on unverified suppliers.Q: Is the CAS number for potassium persulfate different from sodium persulfate?

A: Yes, potassium persulfate has a distinct CAS number: 7727-21-1. Sodium persulfate uses 7775-27-1. Both are oxidizing agents but differ in chemical composition and applications.Q: Why is the CAS number for sodium persulfate important?

A: The CAS number (7775-27-1) ensures precise identification of sodium persulfate in global trade and safety protocols. It mitigates confusion with similar chemicals and aids hazard communication.Q: Where can I find the CAS number for potassium persulfate?

A: The CAS number for potassium persulfate (7727-21-1) is listed on chemical databases, SDS documents, or supplier catalogs. Always confirm it matches your product specifications.-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025