Methods for Producing Calcium Ammonium Nitrate in the Fertilizer Industry

The Manufacturing Process of Calcium Ammonium Nitrate

Calcium Ammonium Nitrate (CAN) is a widely used nitrogenous fertilizer, essential in agricultural practices due to its dual nutritional benefits. As a compound composed of calcium (Ca), ammonium (NH4+), and nitrate (NO3-), CAN plays a significant role in enhancing plant growth and soil health. The manufacturing process of Calcium Ammonium Nitrate involves several steps, each vital to ensure the product's quality and efficacy.

Raw Materials

The production of CAN begins with the procurement of raw materials, primarily ammonium nitrate (AN) and calcium carbonate (CaCO3) or quicklime (calcium oxide, CaO). Ammonium nitrate can be produced by the neutralization of nitric acid (HNO3) with ammonia (NH3). This reaction is highly exothermic and requires careful control of temperature and pressure to avoid hazards.

Neutralization Process

The first major step in the manufacturing process is the neutralization of nitric acid with ammonia. The reaction can be represented as

\[ \text{NH}_3 + \text{HNO}_3 \rightarrow \text{NH}_4\text{NO}_3 \]

This reaction produces ammonium nitrate, which is in a liquid form. After the neutralization, the solution is concentrated through evaporation to achieve the desired concentration. This concentrated solution can then be mixed with calcium compounds.

Formation of Calcium Ammonium Nitrate

Next, the prepared ammonium nitrate solution is mixed with calcium carbonate or calcium oxide. If calcium carbonate is used, it reacts with ammonium nitrate as follows

\[ \text{CaCO}_3 + 2\text{NH}_4\text{NO}_3 \rightarrow \text{Ca(NH}_4)_2\text{(NO}_3)_2 + \text{CO}_2 + \text{H}_2\text{O} \]

In the case of quicklime, the reaction proceeds similarly

\[ \text{CaO} + 2\text{NH}_4\text{NO}_3 \rightarrow \text{Ca(NH}_4)_2\text{(NO}_3)_2 + \text{H}_2\text{O} \]

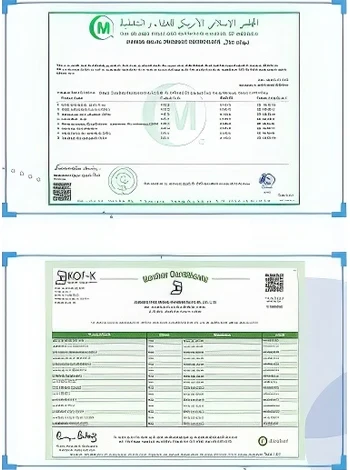

manufacturing process of calcium ammonium nitrate

This step results in the formation of Calcium Ammonium Nitrate, which can be precipitated or allowed to crystallize.

Granulation

Once the CAN is formed, the next step involves granulation to facilitate handling and application. The solution or suspension of Calcium Ammonium Nitrate undergoes a granulation process, where it is transformed into granular form through drying and agglomeration techniques. This step is crucial as it enhances the fertilizer's physical properties, such as solubility and flowability.

There are multiple granulation techniques available, including

1. Drum Granulation In this method, a rotating drum is used where the formed particles collide and stick together, forming larger granules. 2. Fluidized Bed Granulation In this process, tiny particles are suspended in an upward-flowing air stream and come into contact with a binder, which promotes granule formation. 3. Rotary Granulators This method employs a rotating drum that mixes and compresses the raw materials, resulting in larger granules.

The granulation process commonly concludes with drying, where the granules are subjected to hot air to remove excess moisture, ensuring a stable final product.

Screening and Quality Control

After granulation, the granules are screened to obtain uniform particle size. This step is essential to ensure that the product can be easily applied and effectively absorbed by plants. The quality control measures include testing for nutrient content, purity, and physical properties such as size and hardness.

Packaging and Distribution

The final step involves packaging the Calcium Ammonium Nitrate into bags, bulk containers, or other suitable forms for distribution to agricultural suppliers or directly to farmers. Proper labeling is crucial, providing essential information on application rates and storage conditions.

Conclusion

The manufacturing process of Calcium Ammonium Nitrate is intricate, involving multiple chemical reactions and physical processes. From the careful selection of raw materials to the final quality assurance measures, each step is designed to produce a high-quality fertilizer that is efficient and beneficial for agricultural use. Beyond its utility in farming, understanding this production process also highlights the importance of sustainable practices in the fertilizer industry to meet the growing global demand for food production. As agriculture continues to evolve, innovations in the manufacturing process will play a critical role in enhancing the efficiency and sustainability of fertilizer use.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025