25 Percent Sodium Chlorite Solution for Industrial and Sanitation Applications

Understanding Sodium Chlorite 25% Solution Uses, Safety, and Handling

Sodium chlorite is a chemical compound with the formula NaClO2. This white or yellowish crystalline powder is an important intermediate in the production of chlorine dioxide, a powerful bleaching agent and disinfectant extensively used in various industries. Sodium chlorite solutions, particularly the 25% formulation, are critical due to their effectiveness and versatility. This article explores the uses, safety considerations, handling procedures, and regulatory aspects surrounding sodium chlorite 25% solution.

Uses of Sodium Chlorite 25% Solution

Sodium chlorite 25% solution has a multitude of applications, especially in water treatment, industrial processes, and disinfection. One of its primary uses is in the treatment of drinking water. Chlorine dioxide, generated from sodium chlorite, is a highly effective disinfectant that targets bacteria, viruses, and protozoa, ensuring safe drinking water. It is favored for its ability to leave no harmful residuals, unlike traditional chlorine treatments.

In the paper and pulp industry, sodium chlorite is employed in the bleaching process to achieve a bright, white product. Its oxidizing properties efficiently break down lignin, the complex organic polymer that holds wood fibers together, without damaging the cellulose fibers, leading to higher quality pulp.

Moreover, sodium chlorite is used in the textile industry for bleaching, and in the food industry for sanitization of equipment and surfaces. It has also found its way into agriculture, where it is utilized for the sanitization of water used for irrigation.

Safety Considerations

While sodium chlorite is effective and widely used, it also poses certain risks and hazards. It is classified as a strong oxidizing agent, which means it can react violently with reducing agents, leading to fire or explosion hazards. Therefore, proper storage and handling procedures are essential to mitigate risks. Sodium chlorite must be stored in cool, dry, well-ventilated areas away from incompatible substances such as acids, organic materials, and water.

Personal protective equipment (PPE) is crucial when working with sodium chlorite solutions. Protective eyewear, gloves, and appropriate clothing should be worn to prevent skin and eye contact, as the solution can cause irritation. Inhalation of sodium chlorite dust or aerosols can also lead to respiratory issues; therefore, workspaces should be adequately ventilated.

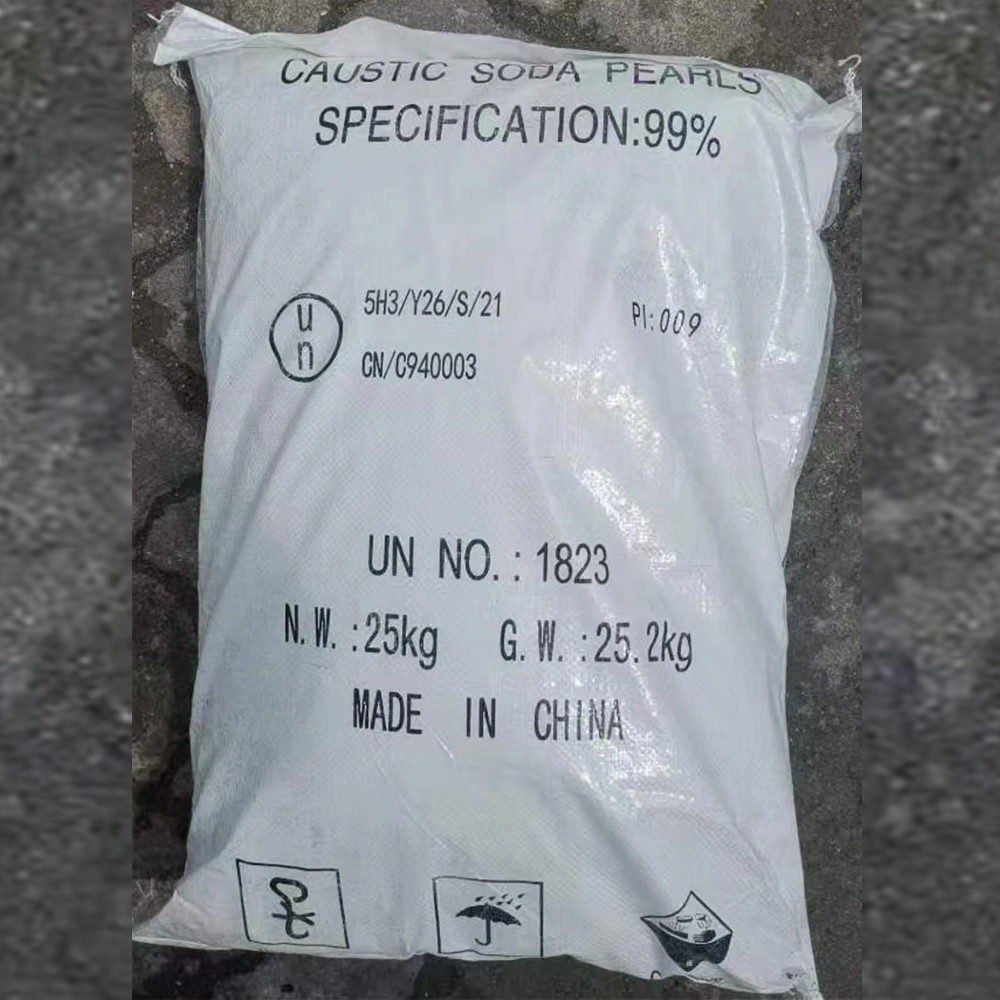

sodium chlorite 25 solution

In case of exposure or spills, it is vital to have an emergency response plan in place. Inhalation of vapors may necessitate moving to fresh air, while skin contact should be treated by rinsing with plenty of water. Eye exposure requires immediate washing with water for at least 15 minutes and seeking medical attention.

Handling Procedures

Handling sodium chlorite 25% solution requires strict adherence to safety protocols. Workers should be trained on the hazards and safe practices associated with the chemical. When measuring or transferring the solution, it is recommended to use appropriate containers and tools made of compatible materials to avoid reactions.

Spill management procedures must be established. In the event of a spill, personnel should don PPE and follow predetermined protocols to contain and clean up the substance. Material safety data sheets (MSDS) should be accessible to all personnel, providing essential information on hazards, first aid measures, and safe handling practices.

Regulatory Aspects

The use of sodium chlorite, especially in food and water applications, is governed by regulatory agencies. In the United States, the Environmental Protection Agency (EPA) regulates its use in drinking water treatment, ensuring that it is safe for human consumption. Compliance with regulations is crucial for manufacturers and end-users to ensure that the chemical is used safely and effectively.

Conclusion

Sodium chlorite 25% solution is a powerful and versatile chemical widely utilized in various industries for disinfection, bleaching, and water treatment. While its benefits are significant, understanding the associated risks and implementing appropriate safety measures is essential to ensure safe usage. Compliance with safety standards and regulations not only protects workers and consumers but also contributes to the responsible management of this important chemical in industrial applications. As industries continue to rely on sodium chlorite, ongoing education about its safe handling and usage will remain critical in maximizing its benefits while mitigating any potential dangers.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025