High-Performance Silicon Carbide Graphite Crucibles for Melting Applications in Various Industries

Silicon carbide graphite crucibles are becoming increasingly popular in various industries due to their remarkable properties and advantages. As a combination of silicon carbide (SiC) and graphite, these crucibles are engineered to withstand extreme temperatures and harsh conditions, making them ideal for metal melting and casting applications.

One of the primary reasons for the widespread use of silicon carbide graphite crucibles is their high thermal conductivity. This property allows for efficient heat distribution, which is essential for processes requiring uniform temperature control. Consequently, these crucibles enable metallurgists to achieve better melting results, ensuring consistent material properties in the end products.

In addition to their thermal performance, these crucibles exhibit excellent resistance to thermal shock. This means they can withstand rapid temperature changes without cracking or degrading, which is a crucial feature when dealing with molten metals. The ability to endure such conditions allows for safer operation and reduces the likelihood of costly failures in the manufacturing process.

Moreover, silicon carbide graphite crucibles are known for their chemical resistance. Unlike traditional crucibles made from materials such as clay or other ceramics, silicon carbide can resist oxidation and corrosion from various molten metals and alloys. This durability translates to a longer lifespan and less frequent replacement, thereby reducing operational costs for manufacturers.

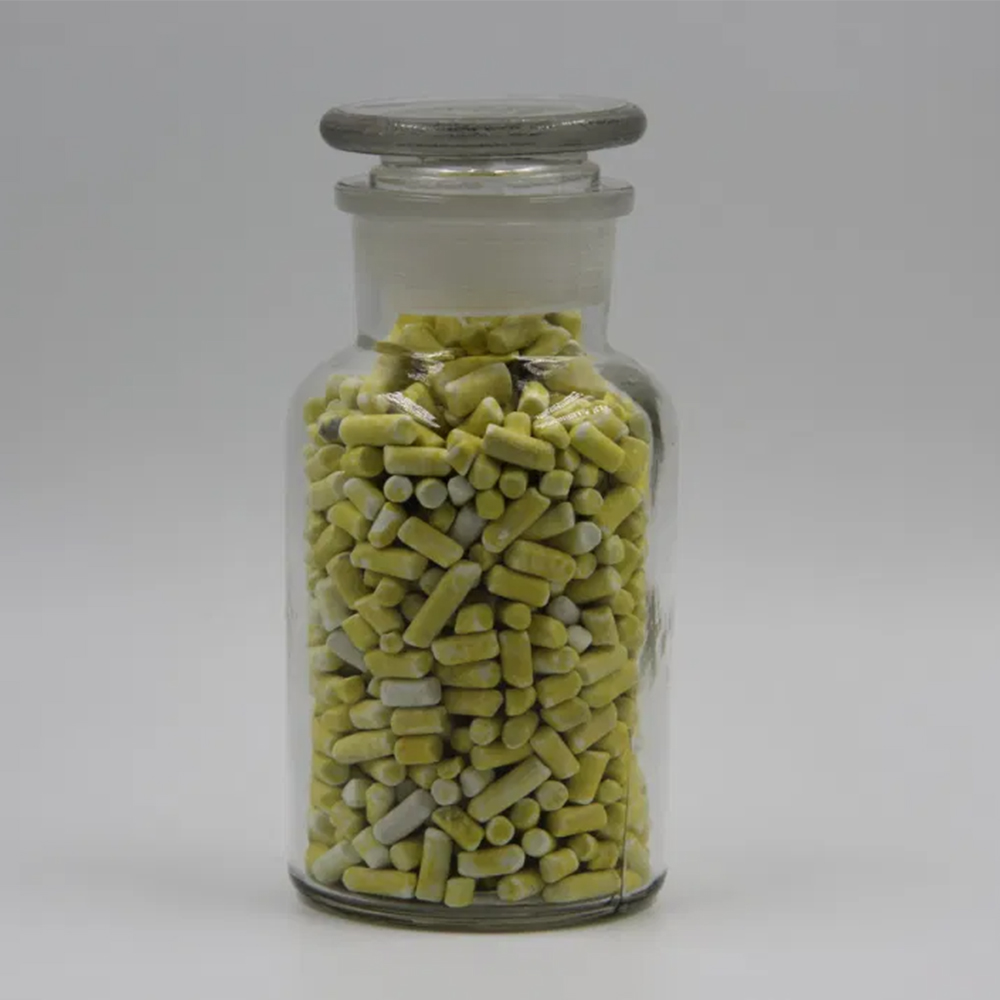

silicon carbide graphite crucibles

The lightweight nature of silicon carbide graphite crucibles also enhances their appeal. Lighter crucibles are easier to handle and require less energy for transportation and installation, contributing to greater overall efficiency in production environments. Additionally, they can be manufactured in various sizes and shapes, catering to specific needs across different industries.

Another significant aspect is the environmental benefits of using silicon carbide graphite crucibles. They are often produced using sustainable practices and materials, aligning with the growing demand for environmentally friendly manufacturing processes. This aspect not only helps in reducing the carbon footprint of operations but also meets the regulatory standards for sustainability.

In conclusion, silicon carbide graphite crucibles represent a significant advancement in crucible technology, offering superior thermal performance, chemical resistance, and durability. Their lightweight and environmentally friendly nature further enhances their utility in various industrial applications. As industries continue to seek innovative solutions to improve efficiency and reduce costs, silicon carbide graphite crucibles are poised to play a vital role in the future of metal melting and casting processes. The ongoing research and development in this area promise even greater enhancements in the performance and sustainability of these crucial tools.

-

Why Strontium Carbonate Still MattersNewsJun.06,2025

-

Why BaSO4 MattersNewsJun.06,2025

-

Why Barium Carbonate Still MattersNewsJun.06,2025

-

Strontium Hydroxide: A Versatile Compound for Modern ApplicationsNewsJun.06,2025

-

Strontium Chloride in Daily IndustryNewsJun.06,2025

-

Pure Potassium Nitrate for SaleNewsJun.06,2025

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025