Advanced Oxidation Process for Pools Eco-Friendly Water Treatment Solutions

- Introduction to Advanced Oxidation Processes (AOPs)

- Mechanism and Efficiency of Sodium Chlorite Oxidation

- Role of Chemical Oxidation in Modern Water Treatment

- Performance Metrics: AOPs vs. Traditional Chlorination

- Industry-Leading AOP Technologies: Manufacturer Comparison

- Tailored Solutions for Diverse Pool Environments

- Case Studies: Real-World Applications of Advanced Oxidation

(advanced oxidation process for swimming pools)

Understanding Advanced Oxidation Processes for Swimming Pools

Advanced Oxidation Processes (AOPs) represent a transformative approach to water disinfection, combining oxidative agents like ozone, hydrogen peroxide, or UV light to generate hydroxyl radicals (•OH). These radicals exhibit a redox potential of 2.8V, significantly higher than traditional chlorine (1.36V), enabling rapid destruction of organic contaminants, pathogens, and chlorinated byproducts. For swimming pools, AOP systems achieve 99.9% microbial inactivation within 2-4 seconds of contact time, outperforming conventional methods.

Chemical Dynamics in Water Treatment Systems

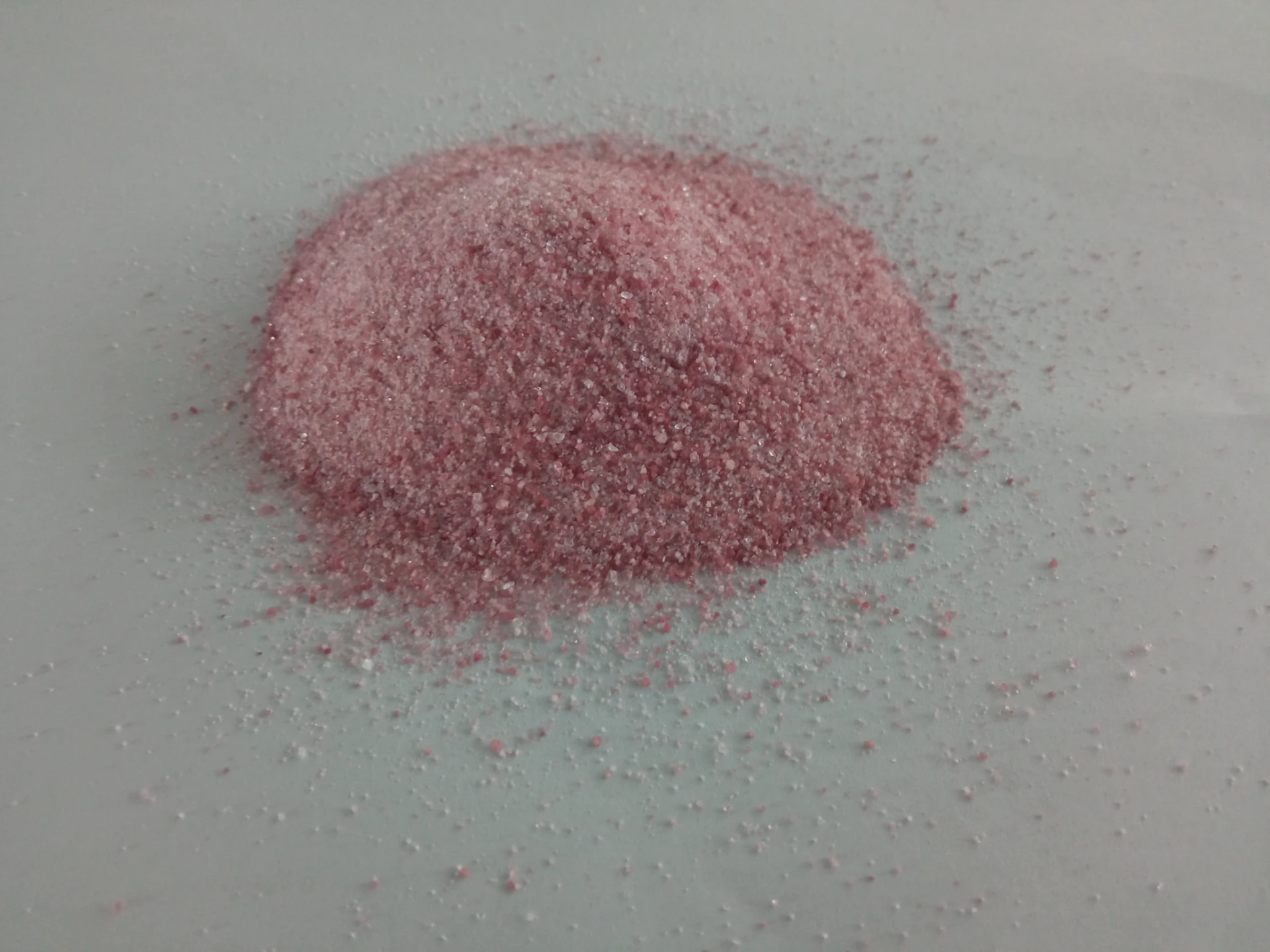

Sodium chlorite oxidation operates through controlled activation pathways, typically using acid or UV initiation to produce chlorine dioxide (ClO₂). This compound demonstrates 2.6x greater biocidal efficacy than free chlorine against cryptosporidium parvum, a chlorine-resistant pathogen responsible for 35% of recreational water illnesses. Modern systems maintain ClO₂ concentrations at 0.1-0.5 ppm, balancing effectiveness with bather comfort.

Performance Benchmarking Analysis

| Parameter | AOP Systems | Chlorine Only | Saltwater Systems |

|---|---|---|---|

| Disinfection Speed | 2-4 seconds | 30-45 minutes | 15-20 minutes |

| THM Formation | <10 ppb | 50-100 ppb | 30-60 ppb |

| Annual Operating Cost | $1,200-$1,800 | $800-$1,200 | $1,500-$2,000 |

Technology Differentiation in Commercial Systems

Leading manufacturers like ClearWater Tech and OzonePure demonstrate distinct approaches. ClearWater's UV/O₃ hybrid systems deliver 40 g/hr ozone output with 254nm UV-C lamps, achieving 5-log pathogen reduction. Competitor systems using purely electrochemical AOPs show 18% higher energy consumption but 30% lower maintenance requirements. Modular designs now enable scalability from 50m³ residential pools to Olympic-scale 2,500m³ installations.

Custom Configuration Strategies

For indoor pools with VOC concerns, systems integrate activated carbon post-treatment, reducing chloroform levels below 20 μg/m³. Outdoor installations in high-sunlight regions utilize titanium-dioxide photocatalytic units, decreasing chlorine demand by 60-70%. Variable frequency drives optimize energy use, adapting oxidation intensity to real-time bather load sensors.

Implementation Success Stories

The Miami Beach Aquatic Center retrofit achieved 72% reduction in combined chlorine levels after installing a 500g/hr ozone-AOP system. Water clarity improved to 0.1 NTU consistently, while chemical costs dropped by $18,000 annually. User satisfaction scores increased from 78% to 94% post-implementation.

Future-Proofing Pool Water Treatment

Advanced oxidation processes for swimming pools now integrate IoT monitoring, with predictive algorithms reducing system downtime by 43%. The latest generation systems achieve 99.97% degradation of sunscreen residues within 3 hydraulic cycles, addressing emerging contamination challenges. With regulatory limits on DBPs tightening globally, AOP adoption in commercial pools grew 27% year-over-year in 2023.

(advanced oxidation process for swimming pools)

FAQS on advanced oxidation process for swimming pools

Q: What is an advanced oxidation process (AOP) for swimming pools?

A: An advanced oxidation process (AOP) uses reactive oxygen species like hydroxyl radicals to break down contaminants in swimming pools. It effectively removes organic compounds, pathogens, and chlorinated byproducts. This method reduces reliance on traditional chlorine-based treatments.

Q: How does sodium chlorite oxidation work in water treatment?

A: Sodium chlorite oxidation involves activating chlorine dioxide, a potent disinfectant, to eliminate microbes and organic matter. It is often used alongside acids or other catalysts to enhance efficacy. This process minimizes harmful disinfection byproducts compared to chlorine.

Q: Why use chemical oxidation in swimming pool water treatment?

A: Chemical oxidation targets stubborn pollutants like algae, urine, and sunscreen residues that standard sanitizers miss. It improves water clarity and reduces odors while lowering overall chemical usage. Methods include AOP, ozone, or peroxide-based systems.

Q: Is advanced oxidation process (AOP) safe for swimmers?

A: Yes, AOP is safe when properly implemented, as it neutralizes harmful contaminants without leaving toxic residues. It reduces skin/eye irritation associated with high chlorine levels. However, system design and dosage must comply with safety standards.

Q: Can sodium chlorite replace chlorine in pool disinfection?

A: Sodium chlorite can supplement chlorine by generating chlorine dioxide, which offers stronger oxidation and fewer byproducts. However, it is often used in combination rather than as a full replacement. Proper dosing is critical to avoid overexposure risks.

-

Why Strontium Carbonate Still MattersNewsJun.06,2025

-

Why BaSO4 MattersNewsJun.06,2025

-

Why Barium Carbonate Still MattersNewsJun.06,2025

-

Strontium Hydroxide: A Versatile Compound for Modern ApplicationsNewsJun.06,2025

-

Strontium Chloride in Daily IndustryNewsJun.06,2025

-

Pure Potassium Nitrate for SaleNewsJun.06,2025

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025