barium sulfate paint

The Applications and Benefits of Barium Sulfate Paint

Barium sulfate paint is a specialized coating that has gained traction in various industries due to its unique properties and versatility. This pigment, derived from the mineral barium sulfate (BaSO₄), is known for its excellent opacity, high brightness, and ability to enhance the texture of paints. Its diverse applications, ranging from automotive to industrial coating, make it a valuable material in the paint industry.

Understanding Barium Sulfate

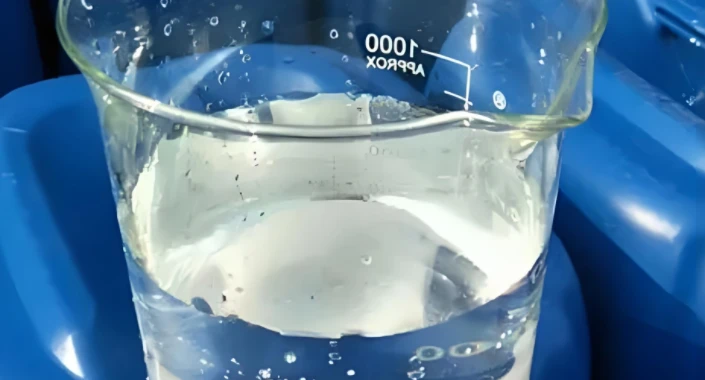

Barium sulfate is a white crystalline solid that is insoluble in water and most organic solvents. Its non-toxic nature and high specific gravity make it an ideal filler in paint formulations. Barium sulfate plays a crucial role in improving the luminescence and durability of paints, allowing manufacturers to create products with enhanced performance characteristics.

The Role of Barium Sulfate in Paint Formulations

One of the primary advantages of using barium sulfate in paint is its ability to provide a high level of hiding power. This means that fewer coats of paint are needed to achieve the desired color and finish. Barium sulfate contributes to the overall coverage of the paint, making it a cost-effective choice for manufacturers. Additionally, it improves the paint’s abrasion resistance and helps to reduce the gloss level, creating a more matte finish if desired.

Moreover, barium sulfate can enhance the weather resistance of exterior paints. Its chemical stability and resistance to UV light mean that paints formulated with barium sulfate can withstand outdoor conditions for prolonged periods without significant degradation. This longevity is particularly beneficial in architectural and decorative applications, where aesthetics and durability are paramount.

Applications Across Industries

barium sulfate paint

Barium sulfate paint is prevalent in various sectors, including automotive, aerospace, and construction. In the automotive industry, it is used in primer and topcoat formulations to provide a smooth finish and excellent adhesion properties. The high opacity of barium sulfate allows for rich color formulations, enhancing the visual appeal of vehicles while providing protection against environmental factors.

In the aerospace sector, the lightweight nature of barium sulfate coupled with its high density makes it a suitable additive for coatings used on aircraft surfaces. The incorporation of barium sulfate helps improve the surface finish and reduces weight, contributing to overall fuel efficiency.

The construction industry also benefits from the use of barium sulfate paint. It is commonly employed in coatings for interior and exterior walls, where its durability and hiding power can significantly improve the appearance and lifespan of buildings. Additionally, barium sulfate can be tailored to meet specific requirements, including color stability and resistance to mold and mildew.

Environmental Considerations

One of the most significant advantages of using barium sulfate in paint formulations is its environmentally friendly profile. Being non-toxic, it poses minimal risk to human health or the environment compared to some alternative pigments. This aspect addresses the growing demand for sustainable materials in the paint industry, aligning with regulations aimed at reducing hazardous substances in consumer products.

Conclusion

Barium sulfate paint represents a remarkable innovation in the coatings industry, offering a blend of performance, versatility, and environmental safety. Its exceptional covering capabilities, durability, and non-toxic nature make it a preferred choice across various applications. As industries continue to push for higher efficiency and quality in their products, the demand for barium sulfate in paint formulations is expected to rise. With ongoing advancements in formulation technologies and a focus on sustainability, barium sulfate paint is poised to play a significant role in the future of the coatings industry. Whether in the automotive, aerospace, or construction fields, the benefits of barium sulfate are undeniable, making it an essential component in modern paint applications.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025