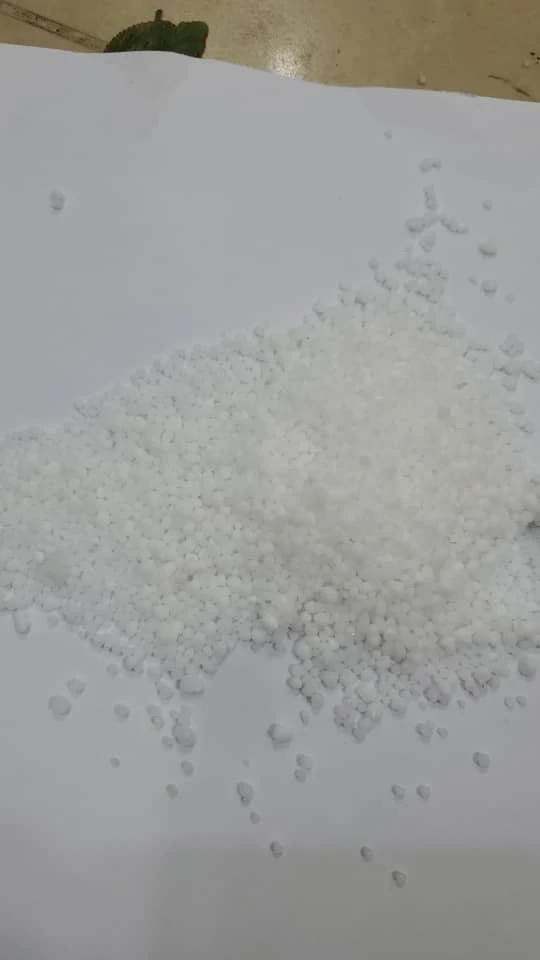

soap making caustic soda

The Art of Soap Making with Caustic Soda

Soap making is an ancient craft that has evolved over centuries to become a popular hobby for many people around the world. One of the key ingredients in traditional soap making is caustic soda, also known as sodium hydroxide. Although it may sound intimidating due to its chemical name, when used correctly, caustic soda is essential for transforming oils and fats into the beautiful bars of soap that we all enjoy.

Understanding Caustic Soda

Caustic soda is a powerful alkali that is highly soluble in water. It is a fundamental component in the saponification process, which is the chemical reaction that takes place when oils or fats are mixed with a strong alkali. During saponification, caustic soda breaks down the triglycerides in fats, resulting in glycerin and soap. However, due to its highly caustic nature, safety precautions must be taken when handling it.

Safety Measures

Before embarking on your soap-making journey, it is crucial to equip yourself with the necessary safety gear. Always wear gloves, goggles, and a mask to protect your skin, eyes, and lungs from any harmful splashes or fumes. Working in a well-ventilated area is also advisable. Furthermore, it is important to keep caustic soda out of reach of children and pets to prevent any accidental ingestion or contact.

Ingredients and Equipment

To make soap using caustic soda, you will need the following

1. Caustic Soda (Sodium Hydroxide) The primary lye used in the soap-making process. 2. Water For dissolving the caustic soda. 3. Fats and Oils Common choices include olive oil, coconut oil, and palm oil. 4. Essential Oils (optional) For fragrance and additional benefits. 5. Colorants (optional) To give your soap a unique appearance. 6. Soap Mold To shape your soap. 7. Thermometer and Scale For accurate measurements and temperature control.

soap making caustic soda

The Soap-Making Process

1. Preparation Begin by measuring out the appropriate amount of caustic soda and water. Always add caustic soda to the water, not the other way around, as this could cause a dangerous reaction. This mixture will heat up rapidly. Allow it to cool while you prepare the oils.

2. Melting Oils Measure and melt your fats and oils in a heat-safe container. The temperature of the oils should ideally be around 100-110°F (37-43°C).

3. Combining Ingredients Once both the lye solution and oils are at the same temperature, slowly pour the lye solution into the oils while mixing with a stick blender or whisk. Blend until the mixture reaches trace, which looks like a thick pudding.

4. Adding Extras At trace, you can add your chosen essential oils and colorants, blending them in thoroughly to ensure an even distribution.

5. Molding and Curing Pour the soap mixture into your mold and smooth the top. Cover it with a towel to keep the heat in, allowing it to saponify over the next 24-48 hours. After this period, unmold your soap and cut it into bars.

6. Curing Allow the soap bars to cure in a cool, dry place for 4-6 weeks. This process ensures that the soap is safe for use, allowing any residual lye to neutralize.

Conclusion

Soap making with caustic soda is a rewarding and creative endeavor that allows you to produce high-quality, natural products for personal use or gifts. By understanding the process and adhering to safety protocols, you can enjoy the journey of crafting your own soap from scratch. Not only will you gain satisfaction from creating something beautiful, but you will also appreciate the craftsmanship involved in transforming simple ingredients into luxurious bars of soap. Happy soaping!

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025