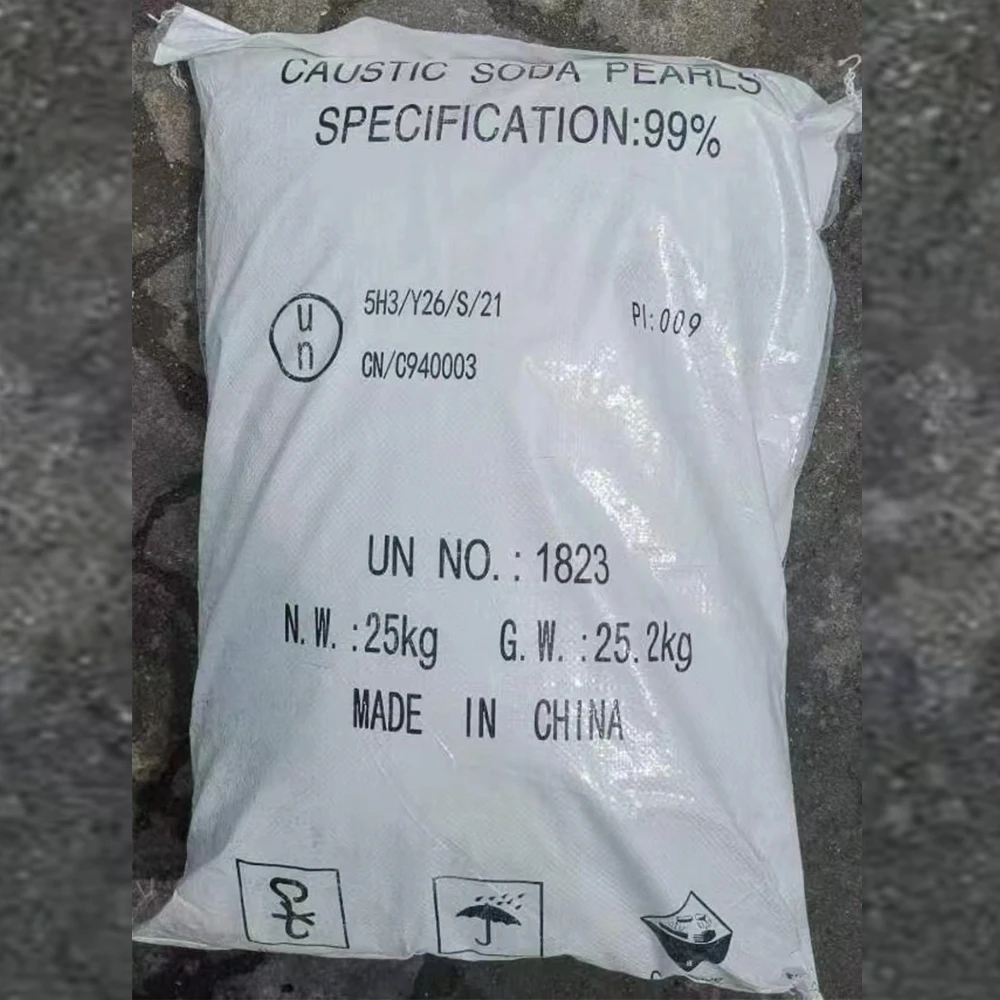

caustic soda chemical

The Importance and Applications of Caustic Soda in Industry

Caustic soda, chemically known as sodium hydroxide (NaOH), is one of the most versatile and widely used industrial chemicals. With its strong alkaline properties, it plays a crucial role in various applications across multiple sectors. This article explores the production, properties, and diverse applications of caustic soda, highlighting its significance in the modern economy.

Production of Caustic Soda

Caustic soda is produced primarily through the electrolysis of sodium chloride (common salt) in a process known as the chloralkali process. In this method, an electric current is passed through a saltwater solution, causing the salt to dissociate into sodium and chloride ions. The sodium ions then react with water, resulting in the formation of sodium hydroxide, hydrogen gas, and chlorine. This process not only yields caustic soda but also produces chlorine and hydrogen, two other valuable industrial chemicals.

The global production of caustic soda is substantial, with millions of tons generated annually to meet the demands of various industries. As an indicator of economic activity, the production levels of caustic soda are often monitored closely, as they correlate with the health of sectors such as textiles, paper, and chemical manufacturing.

Physical and Chemical Properties

Caustic soda is a white, crystalline solid that is highly soluble in water, releasing significant heat in an exothermic reaction. It is highly hygroscopic, meaning it can absorb moisture from the environment. In concentrated form, caustic soda can be caustic and corrosive, capable of causing severe burns upon contact with skin or eyes. Therefore, safety precautions, including proper personal protective equipment and storage methods, are paramount when handling this substance.

Applications of Caustic Soda

caustic soda chemical

1. Chemical Manufacturing Caustic soda is an essential reagent in the production of a variety of chemicals. It is used in the synthesis of detergents, dyes, and fragrances. Furthermore, it serves as a neutralizing agent in the manufacturing of acids and various other compounds, making it a backbone of the chemical industry.

2. Pulp and Paper Industry In the pulp and paper sector, caustic soda plays a vital role in the delignification process, breaking down lignin—the substance that binds cellulose fibers. This process helps in producing high-quality pulp suitable for paper manufacturing. Additionally, it is used in the recycling of paper products, enhancing fiber recovery and quality.

3. Textile Industry Caustic soda is widely utilized in the textile industry for processes such as mercerization, which improves the strength and luster of cotton fibers. It is also employed in dyeing and finishing processes, facilitating better absorption and adherence of dyes to fabrics.

4. Food Industry Although its use in food processing is carefully regulated, caustic soda is employed in certain applications, such as the process of curing olives and softening water for food preparation. It also plays a role in the production of food-grade sodium bicarbonate.

5. Water Treatment In water treatment facilities, caustic soda is used to adjust pH levels, neutralizing acidic water to make it safe for consumption. It helps in the precipitation of heavy metals and aids in removing impurities, ensuring clean, potable water for communities.

6. Energy Sector Caustic soda is instrumental in the production of biodiesel and in the treatment of biofuels. Its role in the saponification process aids in converting fats and oils into biodiesel, contributing to sustainable energy solutions.

Conclusion

The significance of caustic soda in modern industrial applications cannot be overstated. From chemical manufacturing to food processing, its versatility and effectiveness as a powerful alkaline agent have made it indispensable across many sectors. However, with great power comes great responsibility; safe handling and environmental considerations are crucial to mitigate any potential risks associated with caustic soda. As industries continue to evolve, caustic soda's role will likely expand, making it a key player in the drive toward innovation and sustainability in chemical manufacturing and beyond.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025