polyacrylamide production process

The Polyacrylamide Production Process A Comprehensive Overview

Polyacrylamide (PAM) is a versatile polymer widely used in various applications, including water treatment, mining, oil recovery, and as a flocculant in different industrial processes. The production of polyacrylamide involves a series of chemical reactions and processes that convert acrylamide monomers into high-performance polymeric materials. This article provides a comprehensive overview of the polyacrylamide production process, highlighting key steps, safety measures, and environmental considerations.

1. Raw Material Preparation

The first step in the polyacrylamide production process is the preparation of raw materials. The primary raw material is acrylamide, which can be produced from acrylonitrile through a two-step process hydration and ammonolysis. Acryamide is a colorless, crystalline substance that must be handled with care as it is toxic and potentially hazardous. In addition to acrylamide, various additives such as crosslinking agents, stabilizers, and initiators are prepared in precise proportions to achieve desired product characteristics.

2. Polymerization Process

Once the raw materials are in place, the polymerization of acrylamide begins. This process can be conducted through two main methods solution polymerization and emulsion polymerization.

- Solution Polymerization In this method, acrylamide is dissolved in water and heated to initiate the polymerization reaction. A radical initiator, like potassium persulfate or ammonium persulfate, is added to start the chain reaction. The temperature and concentration of the reagents are carefully controlled to ensure optimal reaction conditions. This method often produces polyacrylamide with high molecular weight and uniformity.

- Emulsion Polymerization This technique involves dissolving acrylamide in a monomer mixture along with a surfactant and then polymerizing it in emulsion form. This method allows for the production of polyacrylamide in a solid form, which can be easier to handle and store. Emulsion polymerization often yields polymers with desired characteristics, such as higher flexibility and lower viscosity.

polyacrylamide production process

After polymerization, the resulting polyacrylamide solution goes through a purification process to remove any unreacted monomers and by-products. This step is crucial to ensure the final product is safe for use and meets regulatory standards. Common purification methods include dialysis, precipitation, and filtration.

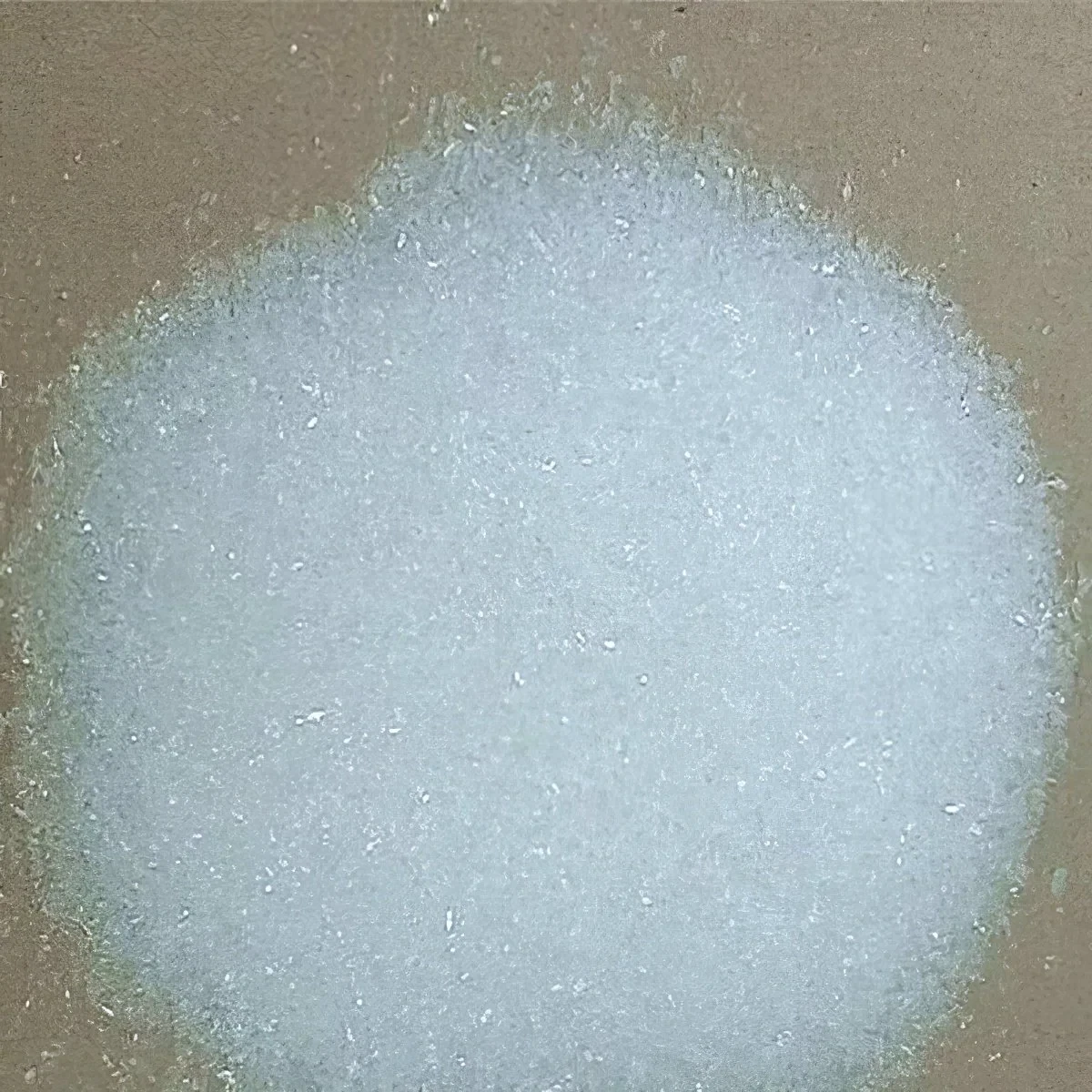

Following purification, the polyacrylamide is typically dried. Various drying techniques can be employed depending on the final product requirements. Spray drying is commonly used to produce a fine powder, while vacuum drying may be employed for larger pellets. The drying process not only removes excess moisture but also helps stabilize the polymer for long-term storage and use.

4. Quality Control and Packaging

Quality control is a critical aspect of polyacrylamide production. Samples from different batches are tested for purity, molecular weight, and performance characteristics. This ensures that the final product meets the specifications required for its intended applications. Once the quality checks are passed, the polyacrylamide is packaged into suitable containers, ready for distribution to various industries.

5. Environmental and Safety Considerations

Throughout the polyacrylamide production process, safety and environmental considerations are paramount. Acrylamide is recognized as a potential carcinogen, and stringent safety protocols must be followed to minimize exposure risks to workers and the environment. Waste management practices should also be in place to handle any by-products or residual chemicals responsibly.

Conclusion

The production of polyacrylamide involves a complex sequence of steps that require close attention to detail and adherence to safety and environmental standards. From raw material preparation to polymerization, purification, and packaging, each stage plays a vital role in ensuring the quality and safety of the final product. As technological advancements continue to improve production efficiency and reduce environmental impact, polyacrylamide will maintain its status as an essential polymer across various industries.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025