Chemical Utilization in Boiler Efficiency and Safety Management Strategies

The Role of Chemical Usage in Boiler Operations

Boilers serve as essential components in numerous industrial and commercial applications, providing heat and power through the combustion of fuels or the utilization of electrical energy. However, to operate efficiently and safely, boilers often require the addition of various chemicals. These chemicals play crucial roles in enhancing performance, improving safety, and ensuring compliance with environmental standards. This article delves into the key chemicals used in boiler systems, their purposes, and the benefits they provide.

1. Water Treatment Chemicals

One of the most critical aspects of boiler operation is the quality of water used. Impurities in water, such as minerals and metals, can lead to scaling and corrosion, which significantly reduce boiler efficiency and lifespan. To mitigate these issues, water treatment chemicals are employed, including

- Oxygen Scavengers Chemicals like sodium sulfite and hydrazine are used to remove dissolved oxygen from the water. Oxygen can lead to corrosion of metal surfaces in the boiler, so controlling its concentration is essential for preserving equipment integrity.

- Scale Inhibitors Compounds such as phosphonates help prevent the formation of scale on the boiler’s heat transfer surfaces, which can obstruct efficiency and heat transfer capabilities. By inhibiting crystal growth, these chemicals maintain smoother operations.

- pH Adjusters Maintaining an optimal pH level is vital for preventing corrosion and scaling. Chemicals such as sulfuric acid or caustic soda are often used to adjust the pH of boiler water, ensuring it remains within suitable limits.

2. Corrosion Inhibitors

Corrosion inhibitors are chemicals added to boiler water to protect the system from corrosive damage. They form a protective layer on metal surfaces, reducing the rate of wear and enhancing the boiler's lifespan. Common corrosion inhibitors include

- Film Formers These create a barrier between water and metal parts, minimizing direct contact and the consequent corrosion process.

- Volatile Corrosion Inhibitors (VCIs) These are chemicals that vaporize and form a protective layer on metal surfaces, providing additional protection even in the presence of moisture.

3. Biocides

In addition to chemical treatments for scaling and corrosion, the presence of bacteria and other microorganisms in boiler systems can lead to biological fouling and corrosion. This can drastically affect the thermal efficiency and safety of the boiler. Biocides are chemicals used to control microbial growth. Common biocides include

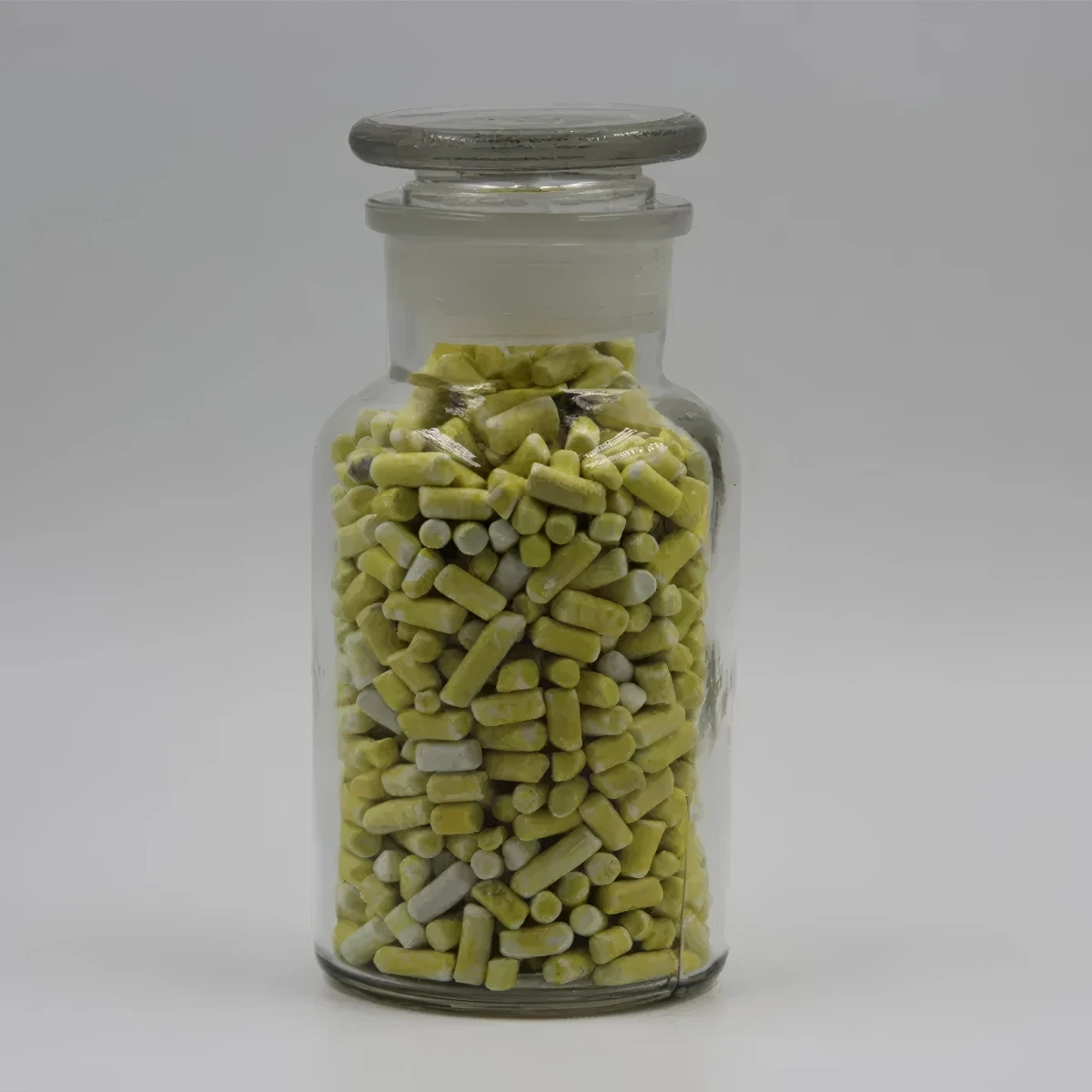

chemical used in boiler

- Bromine-based Compounds These are effective in controlling bacterial growth, particularly in cooling water systems connected to boilers

.- Chlorine-based Compounds Similar to bromine, chlorine compounds are used to disinfect and prevent the growth of microorganisms.

4. Fuel Additives

For boilers that rely on combustion, fuel additives are another category of chemicals used to enhance operational efficiency. These additives can improve fuel quality and reduce ash and emissions. Key fuel additives include

- Combustion Improvers These chemicals help in achieving more complete combustion, thereby reducing unburned fuel, increasing efficiency, and lowering emissions.

- Defoamers Foaming during combustion can impede efficiency. Defoamers work to reduce surface tension in the fuel, minimizing foaming and ensuring smoother operations.

5. Environmental Compliance Chemicals

Adhering to environmental regulations is a significant part of boiler operations. Chemicals are used to reduce harmful emissions and pollutants. Key chemicals include

- SCR Catalysts Selective Catalytic Reduction (SCR) catalysts are used to reduce nitrogen oxides (NOx) emissions from boilers, facilitating compliance with environmental legislation.

- Flue Gas Desulfurization (FGD) Additives These chemicals help to remove sulfur dioxide (SO2) from flue gas, further reducing environmental impact.

Conclusion

The effective use of chemicals in boiler operations is vital for ensuring efficiency, safety, and compliance with environmental standards. From water treatment and corrosion inhibition to fuel additives and biocides, the right selection and application of chemicals contribute significantly to the overall performance of boiler systems. As technology and regulations evolve, staying informed about the latest advancements in boiler chemical treatments will be essential for operators looking to optimize their systems and maintain safe, cost-effective operations.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025