sodium hydroxide manufacturer

Understanding Sodium Hydroxide Manufacturers Their Role and Importance

Sodium hydroxide, commonly known as caustic soda or lye, is a powerful inorganic compound with the chemical formula NaOH. It is represented as a white solid in its pure form, but it is often found in solution in water. This versatile compound plays a crucial role in many industries, including chemical manufacturing, paper production, water treatment, and food processing. Moreover, its production and supply are reliant on sodium hydroxide manufacturers, who are pivotal in meeting the global demand for this essential chemical.

The Role of Sodium Hydroxide in Various Industries

Sodium hydroxide serves numerous purposes across various sectors. In the chemical industry, it is a fundamental reagent in the production of various chemicals, including plastics, detergents, and textiles. In paper manufacturing, it is used in the pulping process to break down lignin, making it easier to extract cellulose fibers from wood. Additionally, sodium hydroxide is a key component in the production of biodiesel, where it acts as a catalyst during the transesterification process.

In the water treatment industry, sodium hydroxide is utilized to raise the pH levels of acidic water, which is essential for effective purification processes. Its role in food processing cannot be overlooked either; it is used for peeling fruits and vegetables, as well as in the production of caramel coloring and other food additives. The versatility of sodium hydroxide is one of the reasons why manufacturers in this field are in high demand.

The Sodium Hydroxide Manufacturing Process

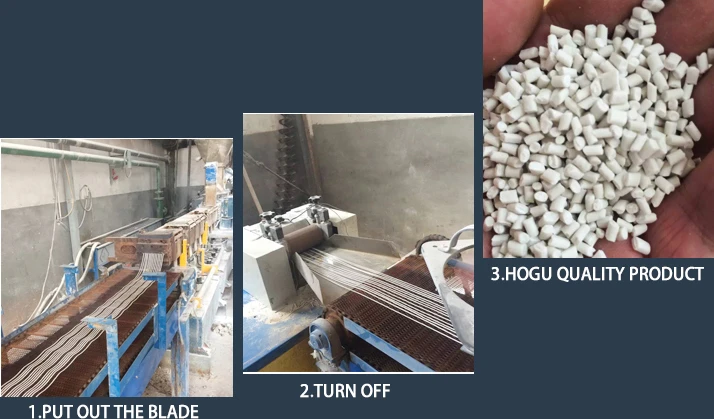

The production of sodium hydroxide typically involves the electrolysis of sodium chloride (table salt) in a process known as the chlor-alkali process. This method not only produces sodium hydroxide but also generates chlorine gas and hydrogen gas as by-products. The chlorine gas is further utilized in the manufacture of various chemicals, while hydrogen has applications in fuel production and industrial processes.

The importance of a high degree of purity in the production of sodium hydroxide cannot be overstated. Manufacturers must adhere to strict regulations and quality control measures to ensure that their products meet industry standards. The specifications for commercial-grade sodium hydroxide often require a purity level of at least 98%, which can significantly affect its applications across different industries.

Choosing a Reliable Sodium Hydroxide Manufacturer

When it comes to sourcing sodium hydroxide, businesses must carefully select their suppliers. A reputable manufacturer will not only provide a high-quality product but also ensure timely delivery and adherence to industry norms. Several factors should be considered when choosing a sodium hydroxide supplier

sodium hydroxide manufacturer

1. Quality Assurance Prospective buyers should inquire about the manufacturing processes and quality control measures in place. A manufacturer that adheres to ISO certification standards usually indicates a commitment to quality.

2. Customer Support Responsiveness and customer service are crucial, especially for industries that may require tailored solutions or adjustments in their order volumes.

3. Logistics and Delivery Sodium hydroxide must be transported safely, given its corrosive nature. A reliable manufacturer will have an efficient logistics system that ensures the product is delivered on time and without contamination.

4. Sustainability Practices As industries move towards greener practices, companies are seeking manufacturers that incorporate sustainable methods in their production processes.

The Future of Sodium Hydroxide Production

As industries evolve, so does the demand for sodium hydroxide. With increasing environmental regulations and the push for sustainable practices, manufacturers are exploring alternative production methods and more efficient processes. For instance, innovations in electrolysis technologies could lead to a reduction in energy consumption during production.

Furthermore, as the global demand for cleaner energy sources grows, sodium hydroxide's role in hydrogen production and fuel cells may become increasingly significant. Manufacturers must stay ahead of these trends to remain competitive in the market.

Conclusion

Sodium hydroxide manufacturers play an integral role in our economy by providing a foundational chemical that drives numerous industries. The demand for high-quality, sustainably produced sodium hydroxide will continue to grow, requiring manufacturers to innovate and adapt. Understanding the importance of these manufacturers helps businesses make informed decisions that ensure the efficiency and effectiveness of their operations in the long run.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025