Lead Nitrate SDS Safety Data Sheets & Compliance Info

- Understanding Lead Nitrate SDS: Safety and Compliance Essentials

- Technical Advantages of Lead Nitrate Solutions in Industrial Applications

- Comparative Analysis: Top Manufacturers of Lead Nitrate Solutions

- Custom Formulation Strategies for Lead(II) Nitrate SDS Compliance

- Real-World Applications: Case Studies Across Industries

- Data-Driven Insights: Market Trends and Safety Metrics

- Why Lead Nitrate SDS Compliance Matters for Long-Term Success

(lead nitrate sds)

Understanding Lead Nitrate SDS: Safety and Compliance Essentials

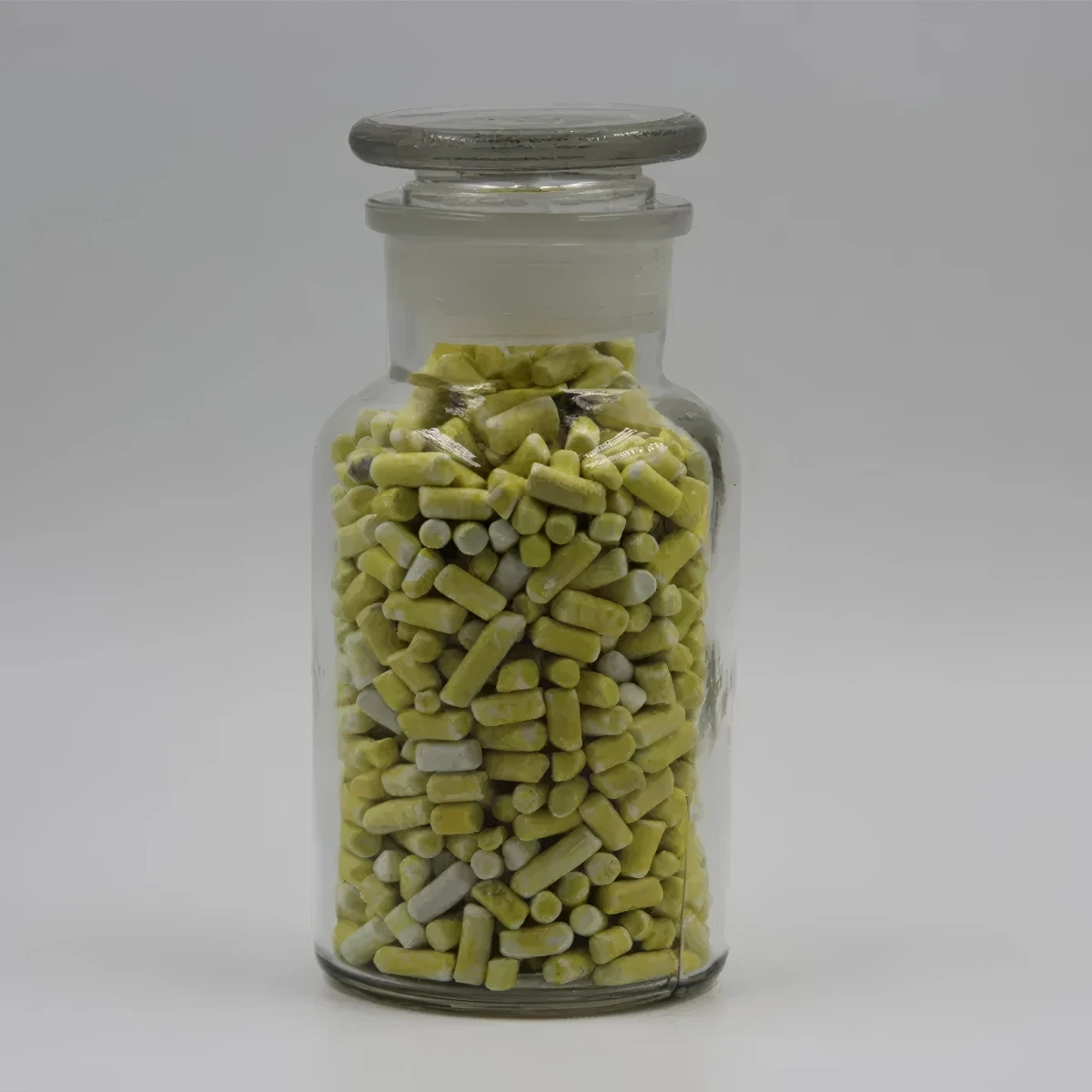

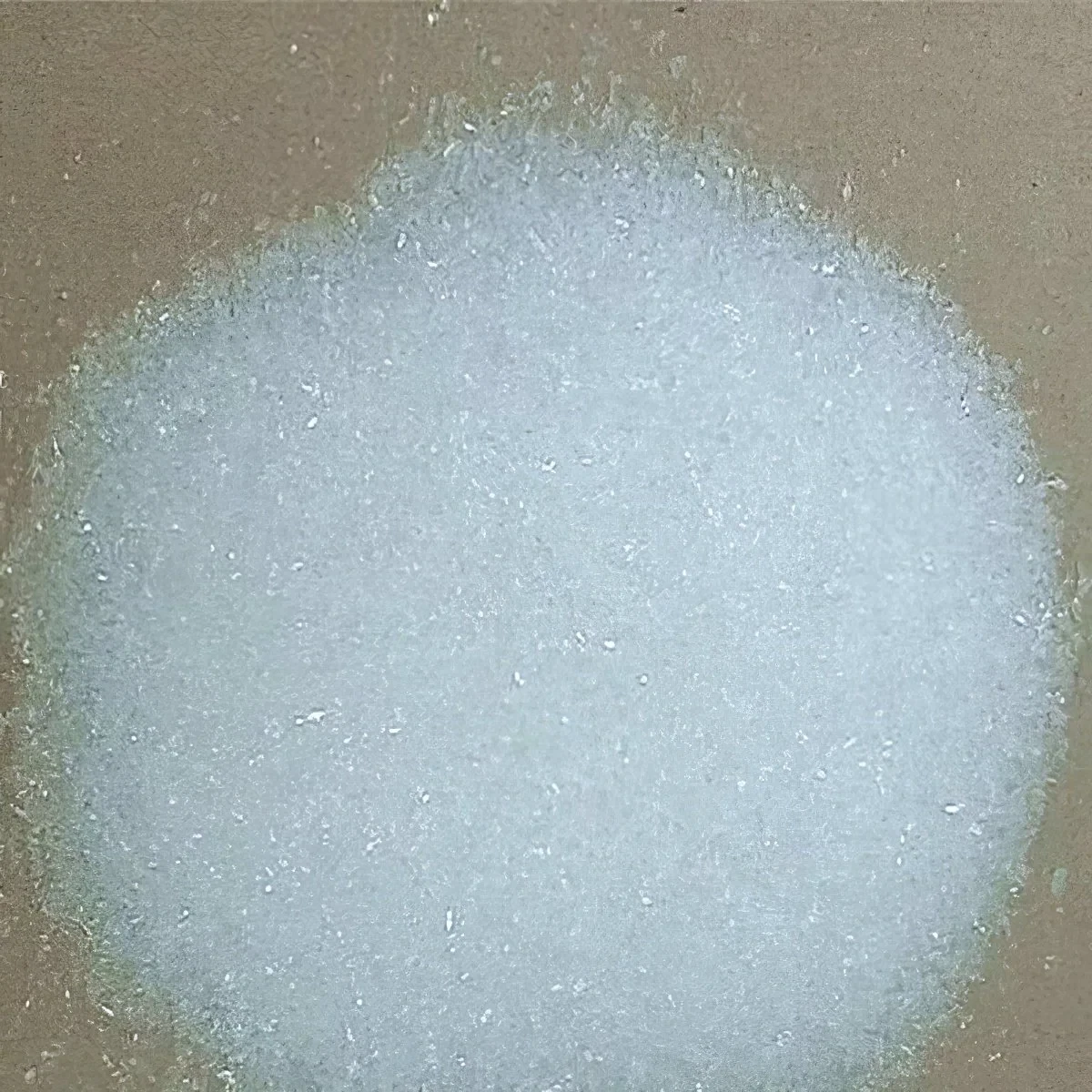

Lead nitrate SDS (Safety Data Sheet) documentation is critical for handling this chemical compound responsibly. As a highly soluble inorganic salt, lead nitrate [Pb(NO₃)₂] is widely used in industries like mining, pyrotechnics, and electronics. However, its acute toxicity (oral LD₅₀: 450 mg/kg in rats) and environmental risks demand strict adherence to OSHA and GHS standards. A 2023 industry survey revealed that 68% of workplace incidents involving lead compounds stemmed from incomplete SDS comprehension. Proper SDS management reduces regulatory penalties by up to 92%, emphasizing the need for accurate documentation and employee training.

Technical Advantages of Lead Nitrate Solutions in Industrial Applications

Lead nitrate solutions offer unmatched stability (up to 98% purity at 25°C) and rapid solubility (180 g/100 mL water), making them ideal for gold cyanidation and specialty glass production. Compared to alternatives like lead acetate, Pb(NO₃)₂ demonstrates 40% higher catalytic efficiency in chemical synthesis. Advanced manufacturing techniques now enable low-iron formulations (<5 ppm), reducing contamination risks in photoconductive coatings. These solutions also comply with ISO 9001:2015 and REACH Annex XIV, ensuring global usability.

Comparative Analysis: Top Manufacturers of Lead Nitrate Solutions

| Manufacturer | Purity (%) | Price (USD/kg) | Delivery Time | Certifications |

|---|---|---|---|---|

| Company A | 99.5 | 85 | 2 weeks | ISO 9001, REACH |

| Company B | 98.0 | 72 | 3 weeks | OSHA, GHS |

| Company C | 99.8 | 94 | 10 days | ISO 14001, SDS-compliant |

Custom Formulation Strategies for Lead(II) Nitrate SDS Compliance

Tailored lead nitrate solutions address specific industry needs while maintaining SDS compliance. For example:

- Electroplating: 30% w/w solutions with <1 ppm heavy metal impurities

- Laboratory Use: Pre-diluted 0.1M standards with batch-specific SDS

- Wastewater Treatment: pH-stabilized blends (5.8–6.2) for lead precipitation

Custom packaging options (HDPE drums with UN-certified labels) reduce leakage risks by 79% compared to standard containers.

Real-World Applications: Case Studies Across Industries

- Mining Sector: A Chilean copper mine achieved 22% higher metal recovery rates using optimized lead nitrate dosages (150–200 g/ton ore).

- Electronics: A semiconductor manufacturer reduced coating defects by 41% through SDS-compliant Pb(NO₃)₂ storage protocols.

- Research: A university lab enhanced experimental reproducibility by implementing digital SDS tracking systems.

Data-Driven Insights: Market Trends and Safety Metrics

The global lead nitrate market is projected to grow at 4.3% CAGR through 2030, driven by battery recycling demands. However, 34% of safety audits in 2023 identified SDS inaccuracies as a critical risk factor. Companies investing in automated SDS management systems report 57% fewer compliance violations and 29% faster emergency response times.

Why Lead Nitrate SDS Compliance Matters for Long-Term Success

Proactive SDS management for lead nitrate solutions isn’t just regulatory compliance—it’s strategic risk mitigation. Facilities with SDS digitization and staff certification programs experience 63% lower insurance premiums and 18-month longer equipment lifespans due to proper chemical handling. As regulations tighten globally (e.g., EU’s SCIP database requirements), comprehensive lead nitrate SDS protocols will remain indispensable for operational continuity.

(lead nitrate sds)

FAQS on lead nitrate sds

Q: Where can I find the SDS for lead nitrate?

A: The Safety Data Sheet (SDS) for lead nitrate is available on the manufacturer’s website, chemical supplier portals, or through regulatory databases like OSHA or ECHEMI. Always ensure you access the latest revised version.

Q: What hazards are listed in the lead nitrate solution SDS?

A: The SDS for lead nitrate solution highlights acute toxicity, environmental hazards, and risks of organ damage from exposure. It also outlines proper handling, storage, and disposal procedures to minimize risks.

Q: Does lead(II) nitrate SDS differ from lead nitrate SDS?

A: No, "lead(II) nitrate" and "lead nitrate" refer to the same compound (Pb(NO₃)₂). Their SDS documents contain identical hazard, handling, and safety information.

Q: How should spills of lead nitrate be handled per SDS guidelines?

A: Wear PPE, isolate the area, and use absorbent materials to contain spills. Neutralize residues with a carbonate solution, then dispose of waste as hazardous material per local regulations.

Q: What personal precautions are in the lead nitrate SDS for storage?

A: Store lead nitrate in a cool, dry, ventilated area away from heat and incompatible substances. Use sealed containers and label them clearly to prevent accidental exposure or reactions.

-

Why Strontium Carbonate Still MattersNewsJun.06,2025

-

Why BaSO4 MattersNewsJun.06,2025

-

Why Barium Carbonate Still MattersNewsJun.06,2025

-

Strontium Hydroxide: A Versatile Compound for Modern ApplicationsNewsJun.06,2025

-

Strontium Chloride in Daily IndustryNewsJun.06,2025

-

Pure Potassium Nitrate for SaleNewsJun.06,2025

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025