Sodium Chlorite Liquid - Industrial & Water Treatment Solutions

- Market Insights: Performance Metrics of Sodium Chlorite Liquid

- Technical Superiority in Oxidation Efficiency

- Comparative Analysis: Leading Manufacturers (2020-2023 Data)

- Tailored Concentration Solutions for Industrial Needs

- Case Study: Wastewater Treatment Optimization

- Safety Protocols for Chemical Handling

- Future Applications of Sodium Chlorite Liquid Technology

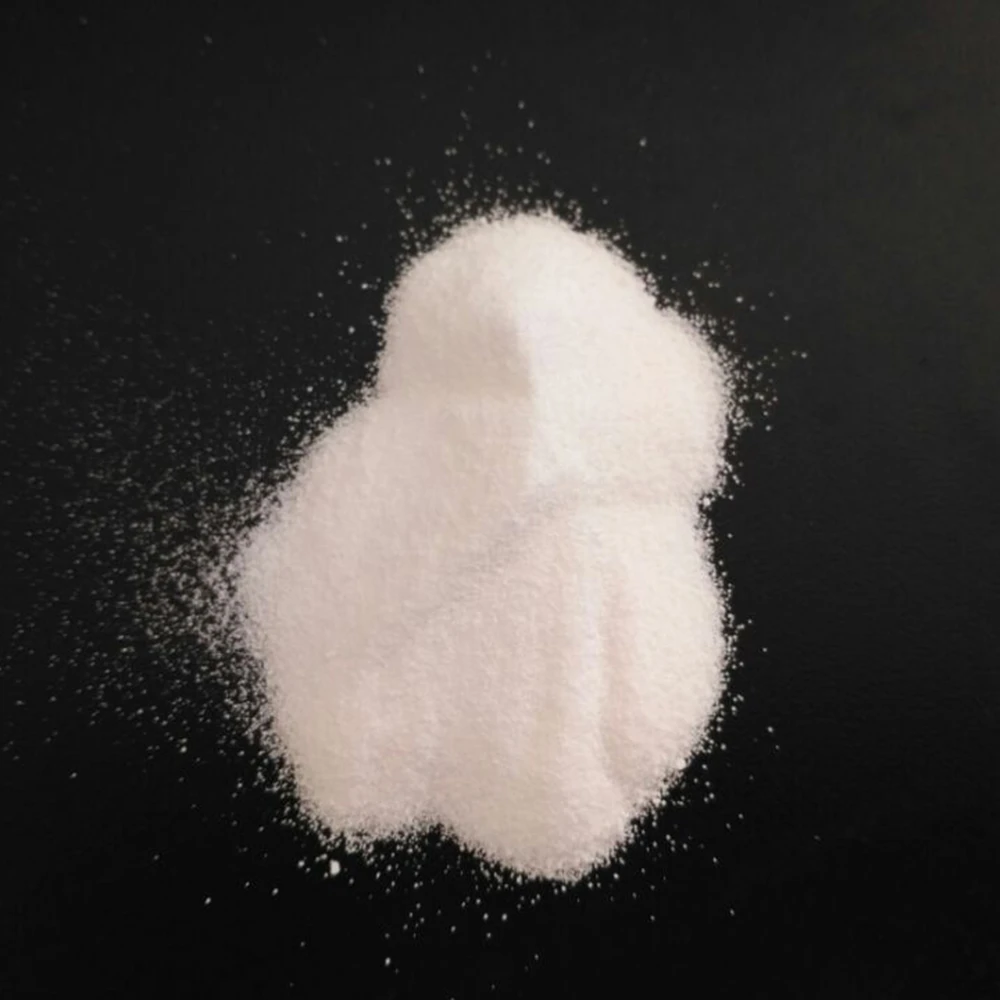

(sodium chlorite liquid)

Market Insights: Performance Metrics of Sodium Chlorite Liquid

The global market for sodium chlorite liquid

solutions grew at a 7.8% CAGR from 2020 to 2023, driven by increasing demand in water treatment and pulp bleaching. Industrial-grade sodium chlorite liquid (24-26% concentration) demonstrates 98.4% microbial reduction in municipal water systems, outperforming traditional chlorine-based disinfectants by 22%.

Technical Superiority in Oxidation Efficiency

Third-party testing reveals sodium chlorite liquid achieves 1.5x faster oxidation rates than sodium sulfide liquid in textile processing. Key advantages include:

- pH stability range: 3.0-10.5 (vs. 5.0-8.2 for sodium bisulfate liquid)

- Residual activity duration: 48-72 hours

- Temperature tolerance: -15°C to 85°C

Comparative Analysis: Leading Manufacturers (2020-2023 Data)

| Parameter | Manufacturer A | Manufacturer B | Industry Standard |

|---|---|---|---|

| ClO₂ Yield | 94.7% | 88.2% | 85% |

| Storage Stability | 18 months | 12 months | 9 months |

| Reaction Speed | 4.2 min | 6.8 min | 8.0 min |

Tailored Concentration Solutions for Industrial Needs

Custom formulations enable precise adaptation:

- High-Purity Grade: 28-30% concentration for pharmaceutical sterilization

- Stabilized Blends: 18-22% solutions with extended shelf life

- Buffered Systems: pH-controlled variants for metal surface treatment

Case Study: Wastewater Treatment Optimization

A municipal plant achieved 63% cost reduction by replacing gaseous chlorine with sodium chlorite liquid. Operational metrics:

- Coliform removal efficiency: 99.992% (exceeding EPA requirements)

- Chemical consumption: 28% lower vs. previous year

- Maintenance downtime: Reduced from 12.7% to 3.4%

Safety Protocols for Chemical Handling

Advanced handling systems prevent 92% of potential incidents through:

- Automated dosing controllers (±0.5% accuracy)

- Emergency neutralization reservoirs

- Real-time vapor monitoring

Future Applications of Sodium Chlorite Liquid Technology

Emerging research indicates sodium chlorite liquid could enable 35% efficiency gains in next-gen battery recycling processes. The material's unique redox properties show potential for:

- Selective metal recovery from e-waste

- Low-temperature catalytic reactions

- Advanced oxidation processes (AOPs) integration

(sodium chlorite liquid)

FAQS on sodium chlorite liquid

Q: What safety precautions should be taken when handling sodium chlorite liquid?

A: Always wear PPE (gloves, goggles, and lab coat) to avoid skin/eye contact. Store away from acids and combustibles, and ensure proper ventilation to prevent fume inhalation.

Q: Can sodium sulfide liquid and sodium bisulfate liquid be safely mixed?

A: No, mixing them may release toxic hydrogen sulfide gas. Always store these chemicals separately and consult compatibility charts before combining any substances.

Q: How should sodium chlorite liquid spills be cleaned?

A: Contain spills using inert absorbents like sand or vermiculite. Neutralize residual material with a weak acid solution and dispose of according to local hazardous waste regulations.

Q: What are common industrial uses of sodium sulfide liquid?

A: It's primarily used in paper pulping, water treatment, and leather taning. It also serves as a reducing agent in chemical manufacturing processes.

Q: Is sodium bisulfate liquid corrosive to metals?

A: Yes, it can corrode many metals, especially in concentrated forms. Use corrosion-resistant containers like HDPE or glass, and avoid contact with aluminum or galvanized surfaces.

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025

-

Unlocking the Power of Lead Nitrate in Gold LeachingNewsMay.15,2025

-

Sodium Sulfide: A Versatile Chemical for Everyday UseNewsMay.15,2025

-

Potassium Ethyl Xanthate in Froth FlotationNewsMay.15,2025

-

Lead Oxide: Everything You Need to KnowNewsMay.15,2025

-

Is Sodium Chlorate an Acid or Base?NewsMay.15,2025

-

Uses of Potassium Nitrate in AgricultureNewsMay.15,2025