Chemical Suppliers for Water Treatment Facilities in Need of Quality Solutions

The Role of Chemical Suppliers in Water Treatment Plants

Water treatment plants are essential facilities designed to ensure the safety and quality of our water supply. They employ a variety of physical, biological, and chemical processes to remove contaminants and produce potable water. Among the key components of this process are the chemicals used by these facilities, which are critical for effective water treatment. In this article, we will explore the role of chemical suppliers in the water treatment industry, the types of chemicals used, and the importance of selecting reliable suppliers.

Understanding Water Treatment Chemicals

Water treatment involves several stages, each requiring specific chemicals to achieve desired results. The most common chemicals used in water treatment can be categorized into several groups

1. Coagulants These chemicals aid in the removal of suspended solids from water. Common coagulants include aluminum sulfate (alum), ferric sulfate, and polyaluminum chloride. They work by destabilizing particles in the water, allowing them to clump together and settle out of the water.

2. Flocculants Once particles have been coagulated, flocculants help to bind them into larger clusters, or flocs, which can be removed more easily. Polyacrylamide is a commonly used flocculant in water treatment processes.

3. Disinfectants Effective disinfection is crucial for ensuring water safety. Chemicals such as chlorine, chloramine, and ozone are widely used to kill or inactivate harmful microorganisms. Selecting the right disinfectant is important for achieving optimal results while minimizing the formation of harmful byproducts.

4. pH Adjusters Maintaining an appropriate pH level in treated water is necessary for optimal coagulation and flocculation, as well as for ensuring the stability of the water and protecting infrastructure. Common pH adjusters include sulfuric acid and sodium hydroxide.

5. Corrosion Inhibitors These chemicals protect pipelines and other infrastructure from corrosion, which can lead to significant maintenance costs and potential contamination of the water supply.

6. Nutrient Additives In some situations, nutrients such as phosphorus and nitrogen may be added to enhance biological treatment processes in wastewater facilities.

water treatment plant chemical suppliers

The Importance of Chemical Suppliers

The role of chemical suppliers in the water treatment industry is critical. A reliable supplier ensures that water treatment plants receive high-quality chemicals that meet regulatory standards. Here are some key reasons why selecting the right chemical supplier is essential

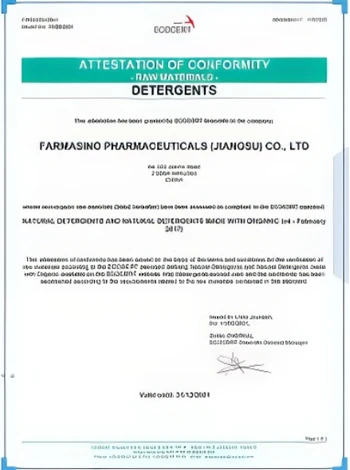

1. Quality Assurance Quality control is vital in water treatment processes. Poor-quality chemicals can lead to ineffective treatment, risking public health and safety. Reputable suppliers provide certifications and documentation to ensure that their products meet safety and performance standards.

2. Consistency and Reliability Water treatment plants operate continuously, relying on a consistent supply of chemicals. Delays or shortages can disrupt operations and compromise water quality. Reliable suppliers maintain appropriate inventory levels to minimize the risk of interruption.

3. Technical Support Many chemical suppliers offer technical support to help water treatment facilities optimize their chemical use. This may include providing guidance on dosage rates, application methods, and troubleshooting issues related to chemical performance.

4. Regulatory Compliance Water treatment plants must adhere to stringent regulatory requirements. Supply chain partners that understand these regulations can help facilities maintain compliance and avoid costly penalties.

5. Cost-effectiveness The efficiency and cost of water treatment processes heavily depend on the quality and pricing of chemicals. Collaborating with suppliers that offer competitive pricing without sacrificing quality can help water treatment plants manage operational costs effectively.

Conclusion

In conclusion, chemical suppliers play an indispensable role in the success of water treatment plants. They provide the necessary chemicals that facilitate the removal of impurities and ensure the production of safe drinking water. Selecting a trustworthy supplier is crucial for maintaining water quality, operational efficiency, and regulatory compliance. As the demand for clean water continues to grow, the partnership between water treatment facilities and chemical suppliers will remain vital in addressing the challenges of modern water treatment. By fostering these collaborations, we can ensure a safer, cleaner water supply for communities around the world.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025