sodium bisulfate vs sodium metabisulfite

Sodium Bisulfate vs. Sodium Metabisulfite Understanding the Differences and Applications

Sodium bisulfate (NaHSO4) and sodium metabisulfite (Na2S2O5) are two important chemical compounds used in various industries, including food processing, water treatment, and pharmaceuticals. Although they share some similarities, their chemical properties, applications, and safety considerations differ significantly. Understanding these differences is crucial for selecting the appropriate compound for specific applications.

Chemical Structures and Properties

Sodium bisulfate, also known as sodium hydrogen sulfate, is an acidic salt formed by the reaction of sulfuric acid with sodium hydroxide. It appears as a white crystalline powder that is highly soluble in water, forming a solution with a pH around 1–2. Sodium bisulfate acts as a mild acid and serves as a pH reducer in various applications.

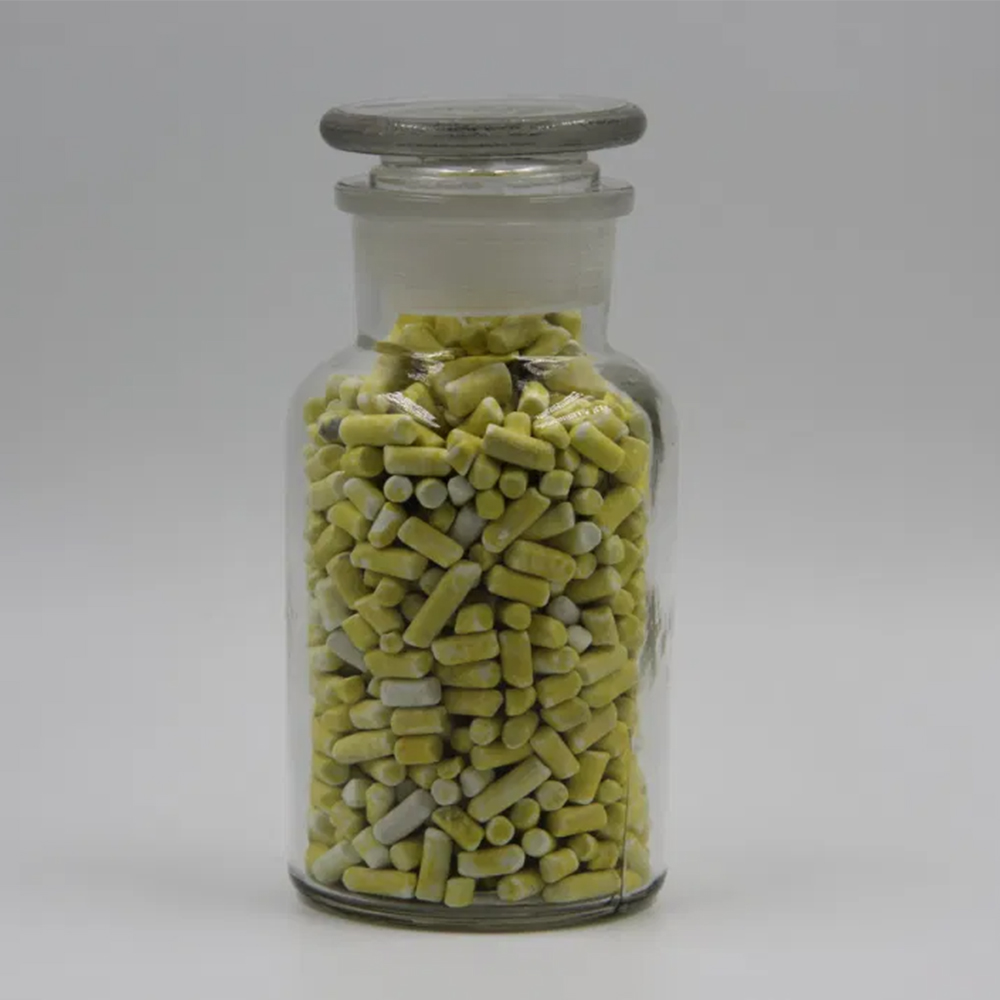

On the other hand, sodium metabisulfite, or disodium disulfite, is a white, crystalline salt that is the result of the dehydration of sodium bisulfite. It has a slightly different chemical structure, containing two sulfite groups linked by a sodium atom. Sodium metabisulfite is also highly soluble in water, and its solution is slightly alkaline with a pH around 4–5. This compound is primarily known for its reducing and antioxidant properties.

Applications

Both sodium bisulfate and sodium metabisulfite find extensive use across several sectors, but their applications often differ based on their chemical properties.

1. Food Industry - Sodium Sorbate Sodium metabisulfite is widely used as a food preservative due to its ability to inhibit the growth of bacteria, fungi, and other microorganisms. It helps in prolonging the shelf life of various products such as dried fruits, wine, and canned vegetables. Sodium bisulfate, while less common as a food additive, can also be used for pH adjustment in certain food processing scenarios. 2. Water Treatment - Both compounds serve critical roles in water treatment. Sodium bisulfate is employed to lower pH in swimming pools and industrial water treatment systems. Its acidic nature helps maintain optimal conditions for disinfection processes. Sodium metabisulfite, in contrast, is mainly utilized as a dechlorinating agent. It scavenges free chlorine in water, making it safer for plants and aquatic life.

sodium bisulfate vs sodium metabisulfite

3. Pharmaceuticals - In the pharmaceutical industry, sodium metabisulfite is often used as a reducing agent and antioxidant in drug formulations and injections, preventing the oxidation of sensitive compounds. Sodium bisulfate, while less common in pharmaceuticals, can be used for pH adjustment in formulations.

4. Textile and Leather Industry - Sodium bisulfate is used in the textile and leather industries for dyeing and finishing processes due to its acidifying properties. Sodium metabisulfite, on the other hand, is widely used in the dyeing process to prevent oxidation and maintain vibrant colors.

Safety and Handling

With their widespread use, it is essential to consider safety precautions when handling these compounds.

- Sodium Bisulfate While it is relatively safe in controlled environments, sodium bisulfate can cause irritation to the skin, eyes, and respiratory system. Proper personal protective equipment (PPE), such as gloves and goggles, should be worn when handling it. - Sodium Metabisulfite This compound also poses potential hazards. It can cause eye and skin irritation and may trigger respiratory issues in sensitive individuals. Additionally, sodium metabisulfite can release sulfur dioxide gas upon contact with acids, which is toxic and irritating. It is crucial to work in well-ventilated areas and use appropriate PPE.

Conclusion

In summary, while sodium bisulfate and sodium metabisulfite may appear similar at first glance due to their chemical composition and applications, their specific properties and uses set them apart. Sodium bisulfate serves primarily as an acidifying agent, whereas sodium metabisulfite functions mainly as a reducing agent and preservative. By understanding the distinctions between these two compounds, industries can make informed decisions that enhance product quality, safety, and efficacy.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025