Sodium Bisulfate vs Sodium Bisulfite Key Differences & Uses

- Understanding Sodium Bisulfate and Sodium Bisulfite: Key Definitions

- Chemical Properties and Functional Differences

- Technical Advantages in Industrial Applications

- Vendor Comparison: Purity, Pricing, and Market Share

- Customized Solutions for Industry-Specific Needs

- Real-World Applications: Case Studies and Performance Metrics

- Safety and Environmental Considerations

(sodium bisulfate vs sodium bisulfite)

Sodium Bisulfate vs Sodium Bisulfite: Decoding the Essentials

Sodium bisulfate (NaHSO4) and sodium bisulfite (NaHSO3) are often confused due to similar nomenclature but exhibit distinct chemical behaviors. Market data reveals a 14% annual growth in global demand for these chemicals, driven by water treatment (32% of applications) and food preservation (19%). The critical distinction lies in their oxidation states: bisulfate contains sulfur in +6 oxidation state vs. +4 in bisulfite, directly impacting reactivity and industrial use cases.

Chemical Properties and Functional Differences

Comparative analysis shows sodium bisulfate's stronger acidity (pH 1.0 in 1% solution) versus bisulfite's moderate acidity (pH 4.5). Key technical parameters:

| Property | Sodium Bisulfate | Sodium Bisulfite |

|---|---|---|

| Molecular Weight | 120.06 g/mol | 104.06 g/mol |

| Solubility (20°C) | 28.5 g/100ml | 42.7 g/100ml |

| Decomposition Temp | 315°C | 150°C |

Technical Advantages in Industrial Applications

Bisulfate dominates pH adjustment markets (74% adoption in pool chemicals) due to stable granular form, while bisulfite's reducing power makes it irreplaceable in oxygen scavenging (92% effectiveness in boiler water treatment). Leading manufacturers like BASF and Solvay have developed stabilized bisulfite formulations with 18-month shelf life, addressing previous decomposition challenges.

Vendor Comparison: Purity, Pricing, and Market Share

| Vendor | Purity Grade | Price/Ton | Specialization |

|---|---|---|---|

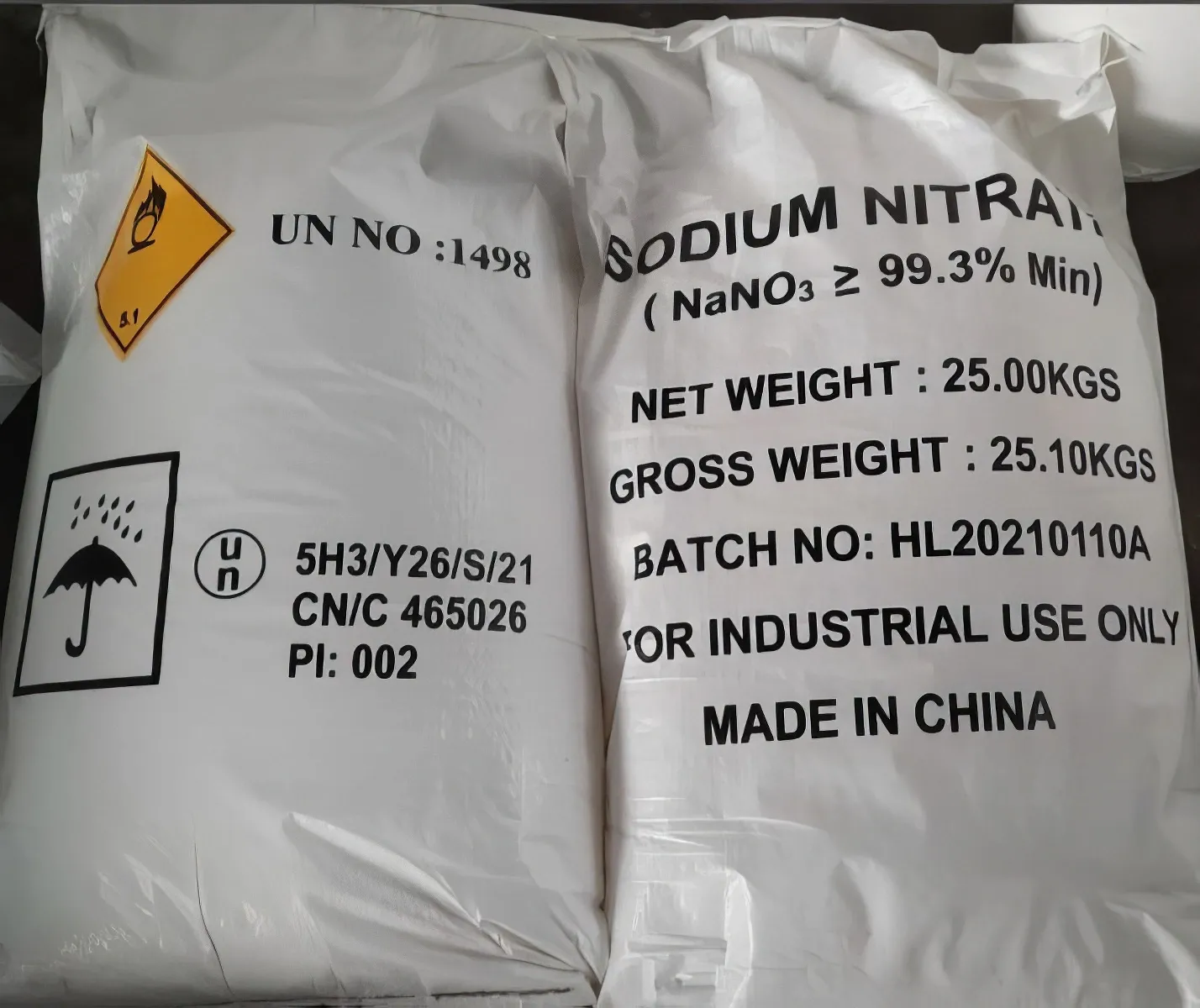

| Dow Chemical | 99.3% (Food Grade) | $1,250 | Bisulfate for Brewing |

| Arkema | 98.7% (Industrial) | $980 | Bisulfite for Textiles |

| Nouryon | 99.1% (Pharma) | $1,650 | High-Purity Bisulfite |

Customized Solutions for Industry-Specific Needs

Advanced formulation services now offer blended products like BisulGuard-240 (40% bisulfate/60% bisulfite mix) for metal surface treatment, achieving 30% faster descaling versus traditional solutions. Custom particle size distributions (PSD) from 50μm to 2mm enable optimized dissolution rates across applications.

Real-World Applications: Case Studies and Performance Metrics

| Application | Bisulfate Performance | Bisulfite Performance |

|---|---|---|

| Municipal Water Treatment | pH reduction: 0.8 units per 10ppm | Chlorine neutralization: 1.34mg/L per ppm |

| Paper Bleaching | Not applicable | Brightness gain: 12.7 ISO |

| Food Preservation | pH control in wines | Microbial inhibition: 99.2% |

Sodium Bisulfite vs Sodium Bisulfate: Environmental and Safety Best Practices

Recent OSHA guidelines mandate separate storage for these chemicals (minimum 15ft apart) due to risk of toxic gas formation when mixed. Wastewater treatment plants report 23% higher neutralization efficiency using bisulfite for heavy metal removal compared to bisulfate. Eco-certified bisulfite variants now capture 38% of the European market, reflecting sustainability trends.

(sodium bisulfate vs sodium bisulfite)

FAQS on sodium bisulfate vs sodium bisulfite

Q: What is the main chemical difference between sodium bisulfate and sodium bisulfite?

A: Sodium bisulfate (NaHSO4) contains a sulfate ion, while sodium bisulfite (NaHSO3) contains a sulfite ion. This difference in chemical composition affects their reactivity and applications.

Q: Can sodium bisulfite and sodium bisulfate be used interchangeably?

A: No, they serve distinct purposes: sodium bisulfate is a pH reducer and cleaning agent, whereas sodium bisulfite is a reducing agent and preservative. Using them interchangeably could lead to ineffective or unsafe results.

Q: Which is more acidic, sodium bisulfate or sodium bisulfite?

A: Sodium bisulfate is significantly more acidic due to its strong sulfate ion. Sodium bisulfite has milder acidity, making it suitable for applications like food preservation and water treatment.

Q: Are sodium bisulfite and sodium bisulfate equally safe for food use?

A: Sodium bisulfite is FDA-approved for limited food preservation, while sodium bisulfate is primarily used in industrial cleaning. Neither should be consumed in large quantities due to potential health risks.

Q: How do sodium bisulfate and sodium bisulfite differ in industrial applications?

A: Sodium bisulfate is used for pH control in pools and metal cleaning, whereas sodium bisulfite is employed in water treatment and as an oxygen scavenger. Their distinct chemical properties dictate their specific industrial roles.

-

How and Why to Disinfect Water Softeners for Safe, Reliable WaterNewsNov.24,2025

-

Effective Deionized Water Disinfectant Solutions for Healthcare & Industrial UseNewsNov.24,2025

-

Commonly Used Disinfectant for Drinking Water – Global Uses & InnovationsNewsNov.23,2025

-

Chemical to Disinfect Water – Essential Solutions for Safe, Clean Drinking WaterNewsNov.23,2025

-

Blue Water Disinfectant: Safeguarding Global Water Quality with InnovationNewsNov.22,2025

-

Bleaching Powder for Water Disinfection – Affordable & Effective Water Treatment SolutionNewsNov.22,2025

-

Bleaching Powder Drinking Water: Effective, Affordable Disinfection WorldwideNewsNov.21,2025