Principles and Applications of Coagulation and Flocculation in Water Purification Processes

Coagulation and Flocculation in Water Treatment An Essential Process for Clean Water

Water treatment is an essential process that ensures the availability of clean and safe drinking water for populations around the world. Among the various techniques employed in water purification, coagulation and flocculation are critical steps that effectively remove suspended particles, colloids, and other impurities from water sources. These processes not only enhance the overall quality of water but also pave the way for subsequent treatment steps such as filtration and disinfection.

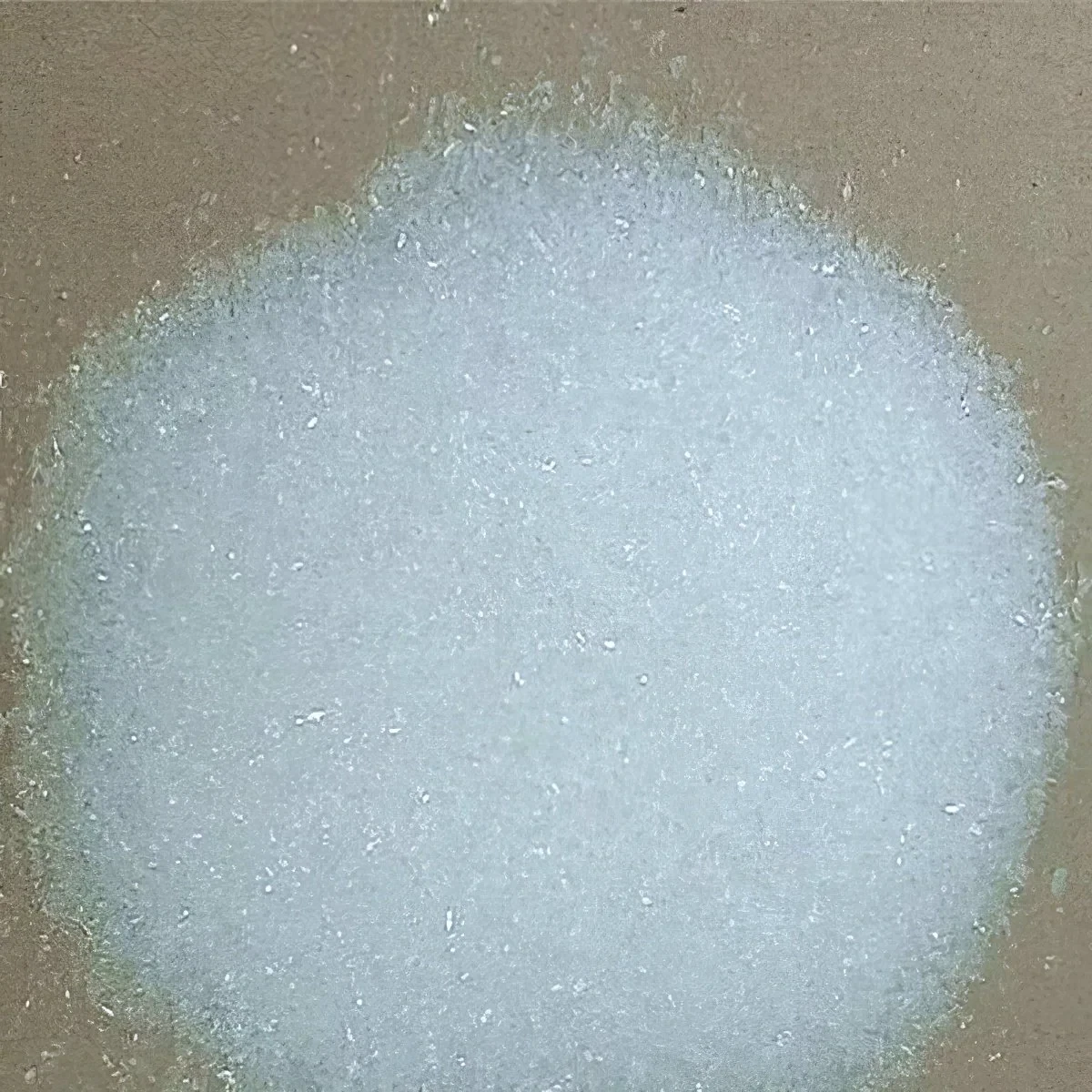

Coagulation is the initial phase of this two-step process and involves the addition of chemical coagulants, such as alum (aluminum sulfate) or ferric chloride, to the water. These coagulants destabilize the finely divided and negatively charged particles suspended in the water. Normally, these particles repel each other due to their like charges, preventing them from clumping together. By neutralizing this charge, coagulants facilitate the aggregation of these particles into larger clusters, known as floc.

Once coagulation has taken place, the next step is flocculation. Flocculation involves the gentle mixing of the water to encourage the growth of these floc particles. This is achieved through slow agitation, which helps the small aggregates collide and bond together to form larger, more easily removable floc. The mixing process is crucial, as it increases the likelihood of particle interaction without breaking apart the already formed floc. The larger floc particles can then be removed efficiently during the sedimentation process.

coagulation and flocculation in water treatment pdf

The effectiveness of coagulation and flocculation is influenced by several factors, including the type and dosage of coagulants used, the pH level of the water, the temperature, and the presence of dissolved organic matter. Operators must carefully monitor these parameters to optimize the treatment process. For example, maintaining an appropriate pH is vital, as varying the pH can enhance the efficiency of the coagulants and improve floc formation. Typically, a pH range of 6 to 8 is considered optimal for aluminum-based coagulants.

Following flocculation, the water enters the sedimentation phase, where the larger floc particles settle out of the water due to gravity. This process can significantly reduce the turbidity of the water, significantly improving its clarity. The settled particles are then removed, and the clearer water proceeds to filtration, where remaining impurities are further eliminated.

While coagulation and flocculation play a vital role in conventional water treatment, their application is equally important in treating industrial wastewater. Many industrial processes generate water that contains fine particles, oils, and suspended solids that must be removed before discharge or reuse. Utilizing coagulation and flocculation not only ensures compliance with environmental regulations but also contributes to resource recovery and sustainable practices.

In summary, coagulation and flocculation are fundamental processes in the treatment of water, both for drinking water supplies and industrial effluents. They effectively reduce suspended solids, improve water clarity, and enhance overall water quality, setting the stage for further purification steps such as filtration and disinfection. As the demand for clean water continues to rise, advancements in coagulation and flocculation technologies remain essential for efficient water treatment solutions. Continuous research and development in this field aim to optimize these processes, ensuring that communities have access to safe and reliable drinking water while protecting our vital water resources for future generations.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025