Exploring the Properties and Applications of Crucible Alumina in High-Temperature Environments

The Significance of Crucible Alumina in Modern Applications

Crucible alumina, a high-purity form of aluminum oxide, is a crucial material in various industrial applications due to its exceptional properties. Known for its high melting point, chemical stability, and thermal resistance, alumina has carved out a significant niche in sectors ranging from metallurgy to ceramics and beyond. This article delves into the characteristics, production processes, and diverse applications of crucible alumina, highlighting its vital role in modern industry.

Properties of Crucible Alumina

Crucible alumina is renowned for its remarkable properties. With a melting point exceeding 2000 degrees Celsius, it can withstand extreme temperatures without degrading. This makes it an ideal material for crucibles, which are used to melt and refine metals. Additionally, alumina is chemically inert; it does not react with most substances, ensuring that it does not contaminate the materials being processed. Its high thermal conductivity allows for efficient heat transfer, while its excellent electrical insulation properties make it suitable for use in electronic components.

Production of Crucible Alumina

The production of crucible alumina involves several stages. Initially, bauxite ore is mined and crushed to obtain aluminum oxide. The Bayer process is then employed to refine this ore, where it is treated with caustic soda under high pressure to extract alumina. The resulting alumina is then calcined at high temperatures to achieve the desired purity and crystallinity. The final product, high-purity alumina, is often used to make crucibles that can endure rigorous manufacturing processes.

Advancements in production techniques have enabled manufacturers to create alumina with varying levels of purity and specific grain sizes tailored for particular applications. For instance, ultra-pure alumina is essential for the production of electronic components, where even minimal impurities can significantly affect performance.

Applications of Crucible Alumina

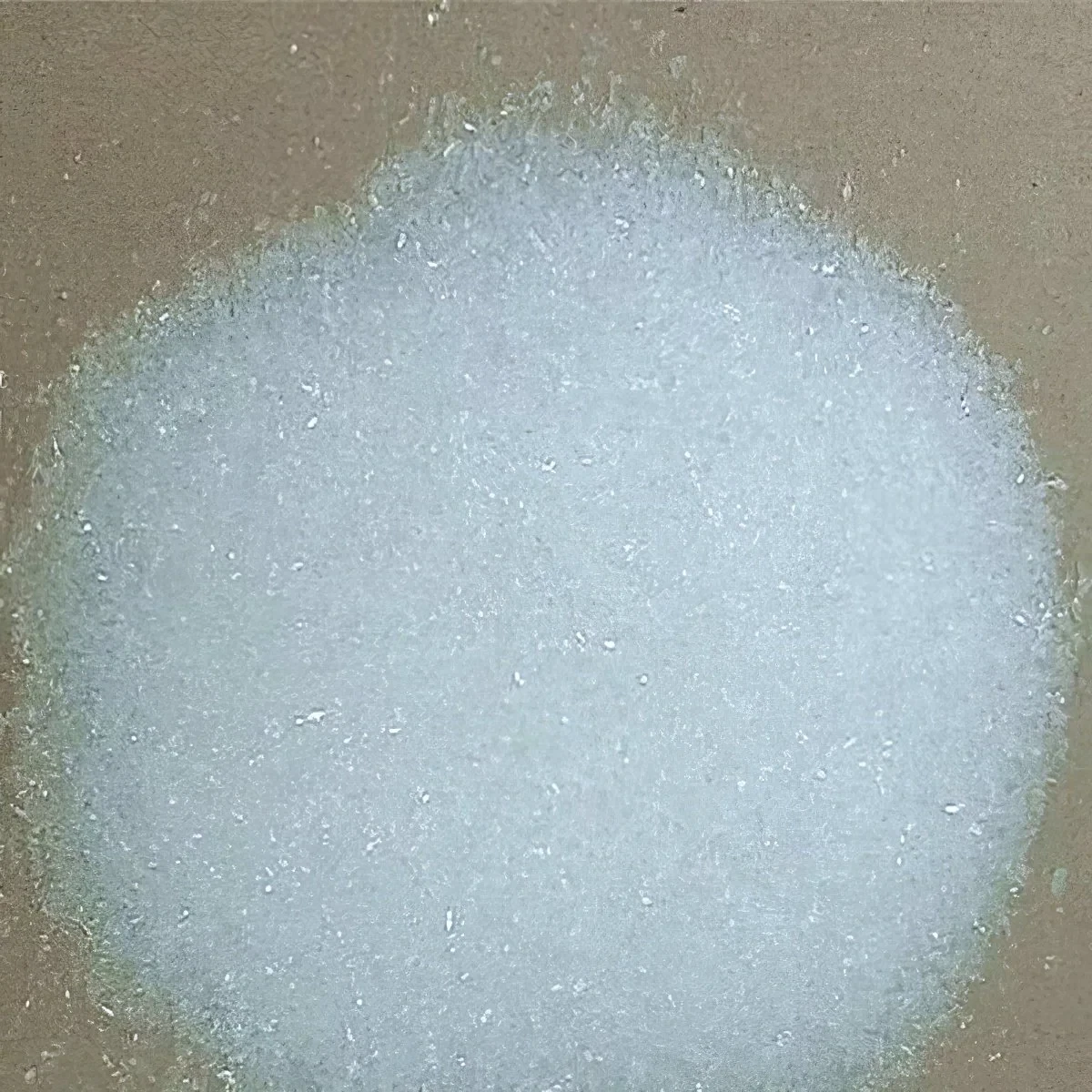

crucible alumina

Crucible alumina finds applications across numerous sectors

1. Metallurgy One of the primary uses of crucible alumina is in the metallurgical industry for melting and refining metals such as gold, silver, and platinum. The ability of alumina to withstand high temperatures makes it ideal for these processes. Additionally, its non-reactive nature ensures the quality of the metal is preserved during melting.

2. Ceramics In the ceramics industry, alumina is a key ingredient in the production of various ceramic products. Its high hardness and wear resistance make it suitable for use in cutting tools, abrasives, and tiles. The addition of alumina to ceramic compositions enhances their mechanical strength and thermal stability, making them suitable for high-performance applications.

3. Electronics The electronic industry utilizes crucible alumina for the fabrication of substrates, insulators, and other components. Its excellent electrical insulation properties allow it to serve as a reliable substrate for mounting electronic circuits, thus ensuring the longevity and efficiency of electronic products.

4. Aerospace and Defense In the aerospace sector, crucible alumina is used in applications that require materials capable of withstanding extreme conditions, including high temperatures and corrosive environments. This includes components in engines and other critical systems. The defense industry similarly benefits from alumina’s robustness and reliability in applications that involve advanced materials.

5. Research and Development In laboratories, crucible alumina is often used for experiments that involve high-temperature processes, such as sintering of materials. Its stability under various conditions allows researchers to conduct experiments without contamination or degradation of materials.

Conclusion

Crucible alumina stands out as a versatile and indispensable material across multiple industries. Its exceptional properties—high thermal resistance, chemical stability, and outstanding mechanical strength—make it ideal for applications requiring durability and reliability. As industries continue to evolve, the demand for high-purity crucible alumina is likely to increase, driven by technological advancements and the endless quest for efficiency and quality in production processes. The continued innovation in the manufacturing of alumina will further enhance its applications, solidifying its role as a cornerstone in modern materials science.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025