Process of Producing Sodium Hydroxide Through Chemical Methods and Reactions

The Making Process of Sodium Hydroxide

Sodium hydroxide, commonly known as caustic soda or lye, is a highly caustic metallic base and alkali salt. It is essential in various industries, including chemical manufacturing, paper production, and food processing. Understanding the making process of sodium hydroxide is critical for both industrial applications and safety. This article will explore the different methods of producing sodium hydroxide, with a focus on the chlor-alkali process, which is the most prevalent and efficient method today.

Introduction to Sodium Hydroxide

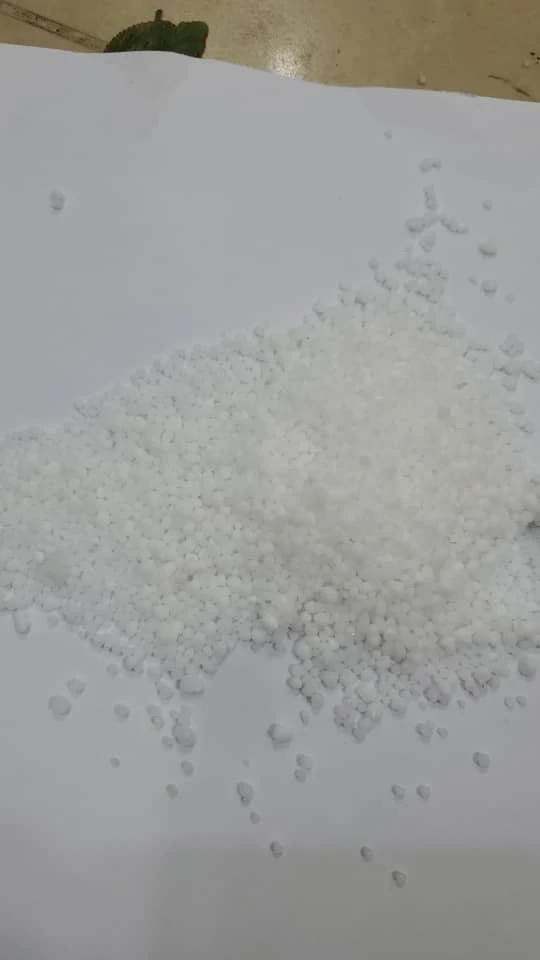

Sodium hydroxide appears as a white solid that absorbs moisture from the air. It is highly soluble in water, releasing heat in an exothermic reaction, which makes it an efficient base for various chemical reactions. Sodium hydroxide is used to manufacture soaps, detergents, and other cleaning agents. Furthermore, it plays a pivotal role in food preparation processes, such as curing olives and making pretzels.

The Chlor-Alkali Process

The major industrial method for producing sodium hydroxide is the chlor-alkali process, which simultaneously produces chlorine gas and hydrogen gas. This process utilizes electrolysis on a solution of sodium chloride (common table salt) dissolved in water. The following steps outline the process in detail

1. Preparation of Brine The first step involves creating a concentrated sodium chloride solution known as brine. This brine can be obtained through dissolving rock salt or sea salt in water.

2. Electrolysis The brine solution is then subjected to electrolysis in an electrolytic cell, which typically consists of a diaphragm-type cell or a membrane cell. During electrolysis, electrical current is passed through the brine, causing the sodium chloride to dissociate into its constituent ions sodium ions (Na⁺) and chloride ions (Cl⁻).

3. Chemical Reactions At the anode (positive electrode), chloride ions are oxidized to form chlorine gas \[ 2Cl⁻ \rightarrow Cl₂(g) + 2e⁻ \] At the cathode (negative electrode), water molecules are reduced, resulting in the formation of hydrogen gas and hydroxide ions \[ 2H₂O + 2e⁻ \rightarrow H₂(g) + 2OH⁻ \]

sodium hydroxide making process

4. Formation of Sodium Hydroxide The hydroxide ions generated at the cathode combine with the sodium ions in solution to form sodium hydroxide (NaOH) \[ Na⁺ + OH⁻ \rightarrow NaOH \]

5. Collection and Concentration The sodium hydroxide solution, along with the produced chlorine gas, is collected. The sodium hydroxide can then be concentrated through evaporation or other means to achieve the desired purity and concentration for industrial use.

Environmental Considerations

While the chlor-alkali process is efficient, it is vital to address its environmental impact. The production of chlorine gas poses risks, requiring stringent safety measures to prevent leakage. Additionally, the disposal of by-products and the energy demands of the electrolysis process are areas of concern. To mitigate these issues, industries are investing in cleaner technologies and exploring alternative methods of production, such as membrane cell technology, which improves efficiency and reduces waste.

Safety Precautions

Sodium hydroxide is highly corrosive and can cause severe burns upon contact with skin or eyes. Proper safety measures should be taken during its production, handling, and storage. Personnel must wear protective clothing, including gloves and goggles, and proper ventilation must be ensured in work areas to prevent inhalation of harmful fumes.

Conclusion

The making process of sodium hydroxide through the chlor-alkali process is a critical aspect of modern chemical manufacturing. Its versatility in various applications makes it an indispensable industrial chemical. However, understanding the production method also highlights the importance of safety and environmental considerations. As the demand for sodium hydroxide continues to grow, ongoing advancements in production technology will further enhance efficiency and sustainability in its manufacturing process. By prioritizing safety and innovation, industries can continue to meet global demands while minimizing their environmental impact.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025