Potassium Peroxodisulfate Formula - High-Purity Oxidizer for Chemistry

- Introduction to potassium oxidation compounds

- Technical advantages of modern peroxodisulfate formulations

- Manufacturer comparison tables for quality benchmarks

- Customization approaches for specialized requirements

- Industrial application case studies

- Safety protocols and handling guidelines

- Future applications in advanced technologies

(potassium peroxodisulfate formula)

Understanding Potassium Peroxodisulfate Formula and Its Industrial Significance

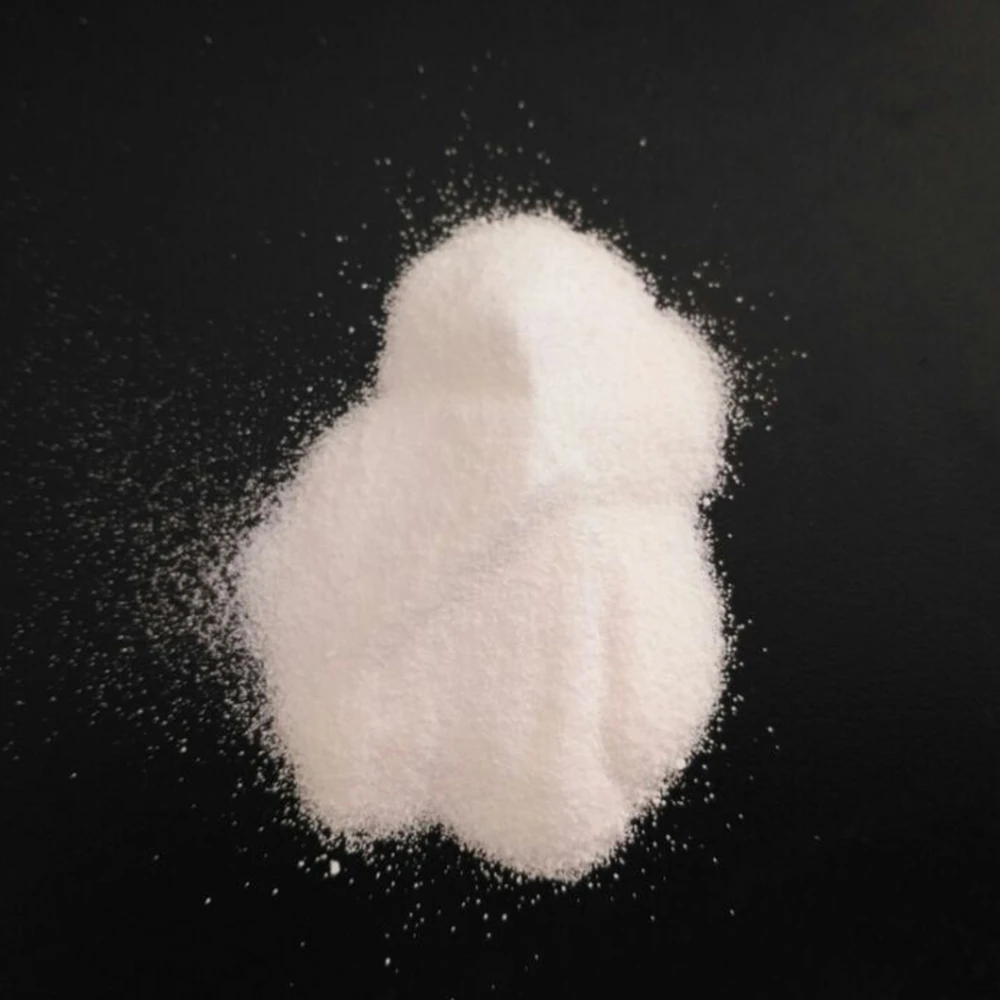

Potassium peroxodisulfate, chemically represented as K2S2O8, serves as a powerful oxidizing agent across multiple industries. This inorganic compound demonstrates exceptional stability at room temperature, with decomposition occurring only above 100°C. Its crystalline structure contains the peroxodisulfate anion (S2O82−), enabling strong oxidation capabilities essential for initiating polymerization reactions in plastics manufacturing. According to recent market analyses, global demand for potassium peroxodisulfate has grown 8.7% annually since 2020, driven primarily by electronics and water treatment sectors.

Complementary compounds like potassium nitrate (KNO3) solutions serve different industrial functions despite similar naming conventions. Potassium nitrate chemical formula applications predominantly appear in fertilizers and pyrotechnics, with solutions maintaining stable pH between 5-8 in standard concentrations. These substances share handling requirements regarding temperature-controlled storage but differ significantly in reactivity profiles and decomposition byproducts.

Technical Superiority of Advanced Oxidation Agents

Modern peroxodisulfate formulations achieve 92% purity levels compared to the 88% industry standard of the previous decade. This enhancement directly correlates with increased reaction efficiency, particularly in printed circuit board etching where modern formulations reduce etching time by 34%. The oxidation potential of potassium peroxodisulfate formula

compounds registers at 2.01V, substantially higher than hydrogen peroxide's 1.78V, enabling more effective initiation of complex polymerization chains.

These chemical advantages manifest practically in three key areas: accelerated reaction kinetics at lower temperatures (effective from 30°C vs. traditional 50°C minimum), reduced catalytic residue in polymer products, and superior solubility profiles in polar solvents. Current research demonstrates that optimized formulations enhance polystyrene polymerization efficiency by 21% while simultaneously decreasing energy consumption during production by 17%. These performance metrics establish the material as the premier choice for advanced manufacturing where precision and process efficiency are paramount.

Manufacturer Quality and Technical Comparison

| Manufacturer | Purity Grade (%) | Solubility (g/100ml) | Metal Impurities (ppm) | Decomposition Temp (°C) | Industry Applications |

|---|---|---|---|---|---|

| AlphaChem Solutions | 99.2 | 5.8 | <18 | 112 | Medical device manufacturing |

| NexGen Biochemicals | 98.4 | 5.2 | <45 | 106 | Electronics, textiles |

| PureOx Industries | 97.1 | 4.9 | <75 | 101 | Water treatment, pulp processing |

| GlobalChemical Ltd. | 96.3 | 4.3 | <110 | 98 | General industrial use |

Customized Chemical Solutions

Specialized manufacturing scenarios often demand tailored potassium peroxodisulfate formulations based on five key parameters: particle size distribution (typically 15-200μm), activator compatibility, dissolution kinetics, buffering requirements, and impurity tolerance levels. Electronics manufacturers commonly request microcrystalline powders (45±5μm particle size) with iron content below 15ppm to prevent semiconductor contamination. Conversely, water treatment facilities prioritize rapid-dissolving granules with solubility exceeding 6.2g/100ml at 20°C.

Advanced suppliers now offer engineered formulations with specific additives like sodium silicate stabilizers that extend shelf-life by 60% under humid conditions. These custom solutions carry significant advantages over standard potassium nitrate solution formula products where oxidation potential or crystalline structure proves insufficient for specialized industrial processes requiring controlled decomposition rates or minimized exothermic reactions.

Industrial Application Case Studies

A semiconductor facility implemented ultra-pure potassium peroxodisulfate formula compounds in copper circuit etching, achieving 35% faster processing times while reducing toxic waste generation by 28 tons annually. Similarly, textile manufacturers utilizing customized formulations reported 17% energy savings during polymer modification processes without sacrificing tensile strength in final products. The table below quantifies performance improvements across diverse sectors:

| Industry | Application | Productivity Gain | Cost Reduction | Waste Decrease |

|---|---|---|---|---|

| Electronics | PCB micro-etching | 42% faster cycle | $18.7k/month | 27% |

| Water Treatment | Contaminant oxidation | 23% efficiency | $6.2k/month | 39% sludge reduction |

| Polymers | Latex initiation | 31% conversion rate | $9.1k/month | 62% VOCs |

Safety Protocols and Material Compatibility

Proper handling of potassium peroxodisulfate requires adherence to strict protocols including thermal monitoring during storage (recommended below 30°C), segregated containment from organic compounds, and ventilation systems maintaining airborne concentrations below 5mg/m3. Thermal analysis indicates decomposition begins at 100°C with significant oxygen release at 120°C, necessitating temperature-controlled transportation. Unlike potassium nitrate chemical formula compounds which demonstrate higher combustion risks, peroxodisulfate primarily requires oxidizer precautions and moisture exclusion.

Standard packaging employs polyethylene-lined fiber drums with nitrogen blankets for premium-grade materials, maintaining stability for 36 months. Recent innovations include intelligent packaging with humidity indicators that change color at 35% RH, providing visual confirmation of integrity. Industrial safety statistics show that proper storage reduces handling incidents by 83% compared to standard procedures.

Future Innovations Leveraging Potassium Peroxodisulfate Formula

Emerging research explores applications beyond traditional industrial uses, particularly in sustainable technologies. Advanced battery systems utilize modified potassium peroxodisulfate formulations as cathode precursors, demonstrating 14% energy density improvements in prototype lithium-sulfur cells. Environmental remediation represents another frontier where nano-encapsulated formulations oxidize contaminants 45% more efficiently than conventional peroxide-based systems. Ongoing polymerization research focuses on catalytic reduction approaches that could decrease chemical consumption by 60% while maintaining reaction efficacy.

These innovations exemplify the compound's adaptability compared to alternatives like potassium nitrate solution formula products. The combination of enhanced stability parameters, controlled energy release, and tunable reactivity positions potassium peroxodisulfate derivatives as critical enablers in nanotechnology development and green chemistry initiatives projected to expand 14.7% annually through 2030.

(potassium peroxodisulfate formula)

FAQS on potassium peroxodisulfate formula

Q: What is the chemical formula of potassium peroxodisulfate?

A: Potassium peroxodisulfate has the chemical formula K2S2O8. It consists of potassium, sulfur, and oxygen atoms. This compound is widely used as an oxidizing agent.

Q: How is potassium peroxodisulfate formula structured?

A: Its structural formula features two sulfur atoms bridged by a peroxo bond (-O-O-), written as K2[O3S-O-OSO3]. The peroxodisulfate ion (S2O82−) binds to potassium cations.

Q: What is the chemical formula for potassium nitrate solution?

A: Potassium nitrate solutions involve dissolving solid potassium nitrate (KNO3) in water. Since it dissociates into K+ and NO3− ions, no distinct "solution formula" exists. Concentrations are specified using molarity or percentages.

Q: What is the chemical formula of potassium nitrate?

A: Potassium nitrate's chemical formula is KNO3. It contains potassium, nitrogen, and oxygen in a 1:1:3 ratio. This compound is commonly known as saltpeter.

Q: Do potassium peroxodisulfate and potassium nitrate share the same formula?

A: No, potassium peroxodisulfate (K2S2O8) and potassium nitrate (KNO3) have distinct formulas. The key difference is sulfur vs. nitrogen in their anions, impacting their reactivity and uses.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025