Chemical Treatment Strategies for Optimizing Chilled Water System Performance

Chemical Dosing in Chilled Water Systems An Overview

In modern HVAC (Heating, Ventilation, and Air Conditioning) systems, chilled water systems play a crucial role in maintaining indoor comfort, especially in commercial buildings and large industrial facilities. To ensure these systems operate efficiently and effectively, chemical dosing has become an essential practice. This article explores the importance, processes, and benefits of chemical dosing in chilled water systems.

The Importance of Chemical Dosing

Chilled water systems are designed to remove heat from indoor spaces and transfer it outside. However, over time, these systems can accumulate contaminants such as scale, corrosion, and biological growth, which can lead to inefficiency and increased energy consumption. Chemical dosing involves injecting specific chemicals into the chilled water system to help mitigate these problems. The principal goals of chemical dosing include

1. Corrosion Prevention Metals used in piping and components, such as copper and steel, are susceptible to corrosion when water chemistry is not properly managed. Corrosive environments can lead to leaks, system failures, and costly repairs.

2. Scale Mitigation Hard water contains high levels of calcium and magnesium, which can lead to scale formation within the system. Scale buildup can significantly reduce heat exchange efficiency and increase energy costs.

3. Biological Control Microbial growth, including bacteria and algae, can thrive in chilled water systems, particularly when conditions are favorable. Chemical dosing helps to control these biological contaminants, preventing fouling and maintaining system performance.

Types of Chemicals Used

Several types of chemicals can be used in the dosing process, including

1. Corrosion Inhibitors These chemicals create a protective layer on metal surfaces, significantly reducing the likelihood of corrosion. Common corrosion inhibitors include phosphonates, nitrites, and molybdates.

2. Scale Inhibitors To prevent the buildup of scale, scale inhibitors alter the crystallization process of calcium carbonate. Common scale inhibitors include polyacrylic acid and phosphonates.

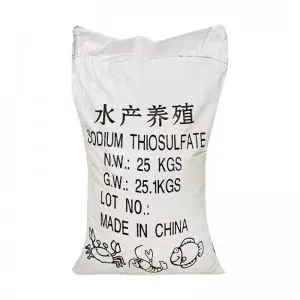

3. Biocides These chemicals are used to control microbial growth in the system. They can include chlorine-based compounds, bromine, or non-oxidizing biocides, which help to maintain hygienic conditions in the chilled water system.

The Dosing Process

chemical dosing in chilled water system

Chemical dosing generally involves several steps

1. Water Quality Analysis Before chemical dosing can take place, a thorough analysis of the water quality is essential. This includes measuring pH, conductivity, hardness, and levels of dissolved oxygen. Understanding the water chemistry allows for targeted dosing strategies.

2. Selecting Chemicals Based on the water quality analysis, appropriate chemical dosing agents are selected to address specific issues such as corrosion, scaling, or microbial growth.

3. Dosing System Setup A chemical dosing system is typically installed to automatically inject the required chemicals into the chilled water system. This system can include dosing pumps, control panels, and monitoring devices to ensure precise application.

4. Monitoring and Adjustment Continuous monitoring is vital to ensure optimal performance. Regular testing of water chemistry enables the system operators to make necessary adjustments to the dosing rates and chemicals used.

Benefits of Chemical Dosing

The integration of chemical dosing in chilled water systems offers several advantages

1. Improved Efficiency By preventing corrosion and scaling, chemical dosing helps maintain the efficiency of heat exchangers and other components, ultimately reducing energy consumption.

2. Extended Equipment Lifespan With reduced corrosion and fouling, the longevity of the chilled water system and its components is greatly increased, leading to lower long-term maintenance costs.

3. Enhanced Water Quality Dosing helps to maintain water quality, ensuring that indoor air quality remains high, which is especially important in commercial settings.

4. Cost Savings While there is an upfront cost associated with chemical dosing systems, the long-term savings from reduced energy consumption, lower maintenance costs, and extended equipment lifespan can be substantial.

Conclusion

Chemical dosing is a fundamental component of maintaining efficient and effective chilled water systems. By addressing corrosion, scaling, and biological growth, proper dosing enhances performance, extends equipment life, and ensures energy efficiency. As technology and methodologies continue to evolve, the future of chemical dosing holds promise for even greater advancements, ensuring that chilled water systems can consistently deliver the comfort and reliability that modern buildings require.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025