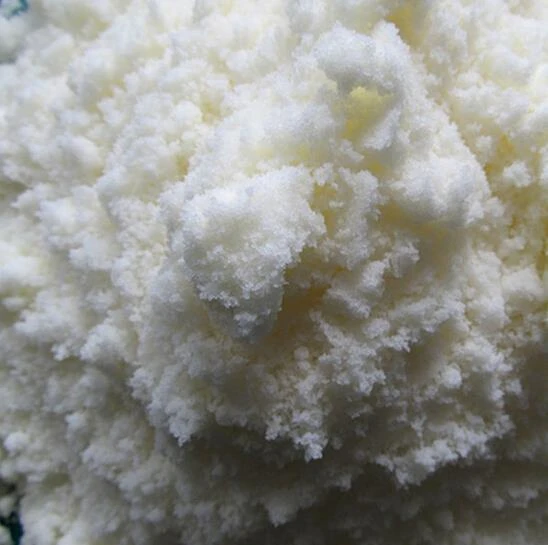

Ferric chloride &Ferric Chloride Liquid 40%

Jan . 30, 2025 06:17

Back to list

Ferric chloride &Ferric Chloride Liquid 40%

Cyanide removal from wastewater is a crucial challenge, especially for industries such as mining, textile, and chemical manufacturing. These sectors often discharge wastewater containing hazardous cyanide compounds, which can have devastating effects on aquatic life and pose severe health risks to humans. This article highlights effective methods for cyanide removal, providing insights gained from industry expertise, authoritative sources, and proven practices, thereby offering a trustworthy resource for businesses seeking sustainable solutions.

The effectiveness of these techniques is backed by authoritative case studies. In one instance, the North American mining sector successfully reduced cyanide discharge by implementing a combination of chemical oxidation and advanced filtration systems. Such authoritative examples underscore the importance of adopting a multi-pronged approach, tailored to the specific needs and scales of operations. Additionally, compliance with international standards, like the International Cyanide Management Code, elevates trustworthiness, demonstrating a company’s commitment to safety and environmental stewardship. Trustworthiness is further enhanced when companies engage with certified engineers and partner with accredited environmental consultants. These professionals bring experience and technical know-how, ensuring that cyanide removal systems are optimized for both efficiency and compliance. Routine audits and continuous monitoring of wastewater discharge play a crucial role in maintaining system integrity and addressing any emerging challenges promptly. In summary, effectively removing cyanide from wastewater requires a careful balance of cutting-edge technologies, expert implementation, and adherence to best practices. By drawing on industry expertise and relying on authoritative case studies, businesses can navigate the complexities of cyanide removal with confidence. Prioritizing sustainability and safety not only ensures compliance but also enhances corporate image and stakeholder trust. As environmental concerns amplify globally, the push towards innovative and responsible waste management solutions remains more critical than ever.

The effectiveness of these techniques is backed by authoritative case studies. In one instance, the North American mining sector successfully reduced cyanide discharge by implementing a combination of chemical oxidation and advanced filtration systems. Such authoritative examples underscore the importance of adopting a multi-pronged approach, tailored to the specific needs and scales of operations. Additionally, compliance with international standards, like the International Cyanide Management Code, elevates trustworthiness, demonstrating a company’s commitment to safety and environmental stewardship. Trustworthiness is further enhanced when companies engage with certified engineers and partner with accredited environmental consultants. These professionals bring experience and technical know-how, ensuring that cyanide removal systems are optimized for both efficiency and compliance. Routine audits and continuous monitoring of wastewater discharge play a crucial role in maintaining system integrity and addressing any emerging challenges promptly. In summary, effectively removing cyanide from wastewater requires a careful balance of cutting-edge technologies, expert implementation, and adherence to best practices. By drawing on industry expertise and relying on authoritative case studies, businesses can navigate the complexities of cyanide removal with confidence. Prioritizing sustainability and safety not only ensures compliance but also enhances corporate image and stakeholder trust. As environmental concerns amplify globally, the push towards innovative and responsible waste management solutions remains more critical than ever.

Latest news

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025