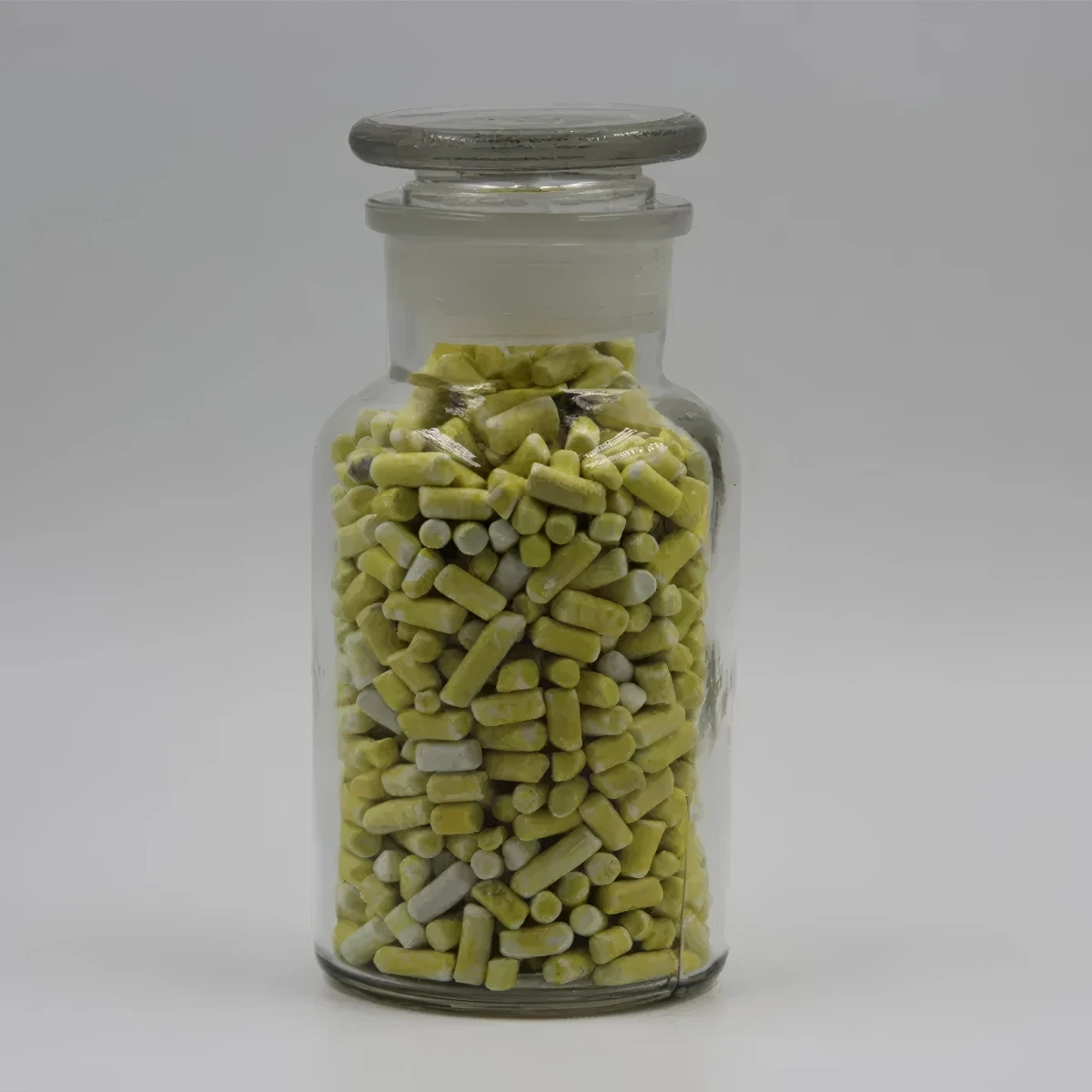

barium carbonate manufacturer

The Role of Barium Carbonate Manufacturers in Modern Industries

Barium carbonate, a chemical compound represented by the formula BaCO3, is an important raw material used in various industries. Barium carbonate manufacturers play a crucial role in producing this compound, which serves diverse applications, including ceramics, glass, chemicals, and environmental management. This article delves into the significance of barium carbonate, the processes involved in its production, and the impact of manufacturers in meeting the global demand.

Understanding Barium Carbonate

Barium carbonate is a white crystalline powder that is insoluble in water but soluble in acids. It is primarily derived from barite, a naturally occurring mineral that comprises barium sulfate (BaSO4). The conversion of barite to barium carbonate typically involves a reactive process. The compound is valued for its properties, including its ability to act as a flux in ceramics and glass production, where it helps to lower melting temperatures and improve the quality of the final product.

Applications of Barium Carbonate

1. Ceramics and Glass Manufacturing One of the most significant applications of barium carbonate is in the ceramics industry, where it is used in the production of glazes, porcelain, and tiles. The compound assists in achieving desired aesthetic properties and enhances the durability of ceramic products. In glass manufacturing, barium carbonate serves as a flux that improves the melting process and enhances the glass's optical properties.

2. Chemical Production Barium carbonate is used in the synthesis of various barium compounds, such as barium hydroxide and barium oxide, which have their own unique applications in different chemical processes. Its reactivity with acids allows for the production of salts used in various industrial applications.

3. Environmental Applications In environmental management, barium carbonate is employed in wastewater treatment processes to remove contaminants and heavy metals from water sources. Its ability to precipitate certain metals makes it valuable in safeguarding water quality.

4. Agriculture Another application of barium carbonate is found in agriculture, where it is used as a source of barium for plants. This usage, however, must be managed carefully due to the potential toxicity of barium compounds.

The Manufacturing Process

barium carbonate manufacturer

Barium carbonate manufacturing typically involves several key steps

1. Raw Material Acquisition The primary raw material for producing barium carbonate is barite, which is mined and crushed into a fine powder.

2. Chemical Reaction The crushed barite is then mixed with a solution of sodium carbonate (soda ash) where a double displacement reaction occurs. This process results in the formation of barium carbonate, which precipitates out of the solution.

3. Filtration and Washing The precipitate is then filtered and washed to remove any impurities, ensuring that the final product meets the required purity standards.

4. Drying and Milling After washing, the barium carbonate is dried and milled to obtain the desired particle size for various applications.

5. Quality Control Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the product complies with industry standards and specifications.

Challenges and Considerations

Barium carbonate manufacturers face various challenges, including fluctuating raw material prices, stringent regulations on hazardous substances, and the need for sustainable production practices. Environmental concerns regarding barium toxicity require careful handling and disposal of waste products. Manufacturers must invest in research and development to improve processes and minimize environmental impact while ensuring product quality and safety.

Conclusion

Barium carbonate manufacturers are vital players in various industries, providing essential materials that facilitate advancements in technology, construction, and environmental remediation. As global demand for barium carbonate continues to grow, manufacturers must navigate challenges while striving for responsible production practices. The ongoing development and innovation in this field are crucial for maintaining a balance between industrial growth and environmental stewardship. Understanding the intricate processes that barium carbonate manufacturers engage in not only highlights their importance in the supply chain but also underscores the necessity for sustainable practices in chemistry and manufacturing.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025