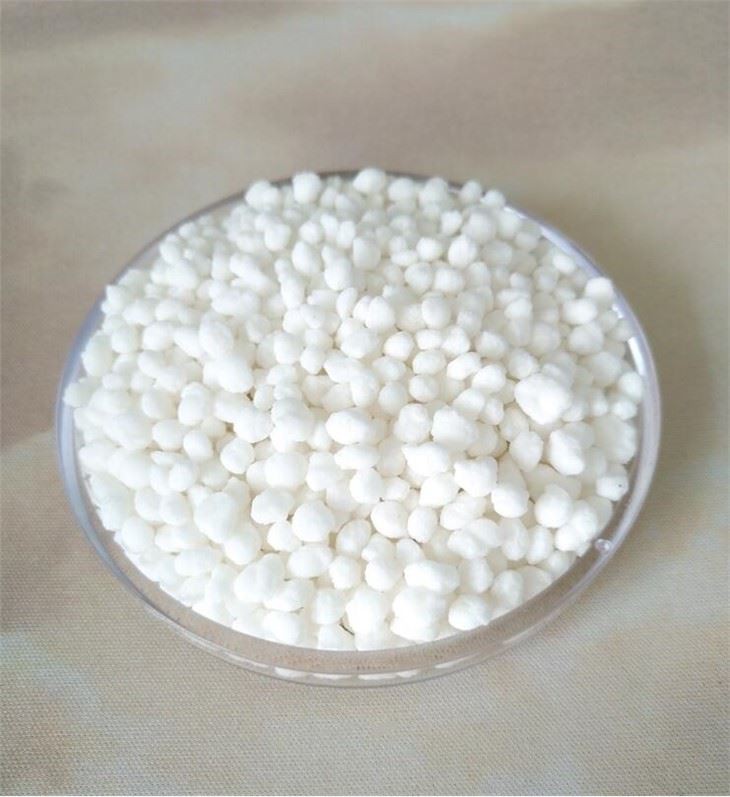

Custom Anionic Polyacrylamide Solutions for Diverse Industrial Applications and Environmental Needs

Understanding OEM Anionic Polyacrylamide Applications and Benefits

Anionic Polyacrylamide (PAM) is a water-soluble polymer that has gained popularity across various industries due to its unique properties and versatility. In the realm of manufacturing, Original Equipment Manufacturers (OEM) often seek specialized chemical solutions to enhance their products' effectiveness. This article delves into the significance of OEM Anionic Polyacrylamide, focusing on its characteristics, applications, and the benefits it brings to various sectors.

What is Anionic Polyacrylamide?

Anionic Polyacrylamide is a linear polymer with anionic properties, which means it carries a negative charge. This charge enhances its functionality in different applications, particularly in water treatment, soil stabilization, mineral processing, and oil recovery. The polymer is synthesized through a process that involves the polymerization of acrylamide, providing a product that can be customized for various industrial needs.

OEM Anionic Polyacrylamide Tailored Solutions

The term OEM refers to manufacturers who produce components that are used in another company's end product. In the context of Anionic Polyacrylamide, OEM suppliers provide tailored solutions that meet specific customer requirements. This customization can include variations in molecular weight, charge density, and formulation adjustments to ensure optimal performance in different applications.

Key Applications

1. Water Treatment One of the primary uses of Anionic Polyacrylamide is in water treatment processes. It serves as a flocculant, facilitating the aggregation of suspended particles, which enhances the efficiency of sedimentation and filtration processes. By using OEM-grade Anionic PAM, treatment facilities can achieve higher water quality with reduced chemical usage.

2. Soil Stabilization In the construction and agricultural sectors, Anionic Polyacrylamide is employed to improve soil structure and reduce erosion. It increases the water retention capacity of soil, promotes seed germination, and enhances crop yield. OEM formulations are particularly beneficial as they can be designed to suit specific soil types and environmental conditions.

oem anionic polyacrylamide

3. Mineral Processing In mining operations, Anionic Polyacrylamide is utilized to improve the separation of valuable minerals from ore. Its ability to increase the settling rate of solids helps in the effective recovery of minerals, reducing waste and optimizing resource extraction.

4. Oil Recovery Enhanced oil recovery (EOR) techniques often incorporate Anionic Polyacrylamide to increase the viscosity of the injected water, improving the displacement of oil from reservoirs. OEM suppliers can develop specialized formulations that enhance performance in specific geological conditions.

Benefits of Using OEM Anionic Polyacrylamide

1. Improved Efficiency Custom formulations provide targeted solutions that enhance process efficiency, whether it's in wastewater treatment, soil stabilization, or mineral processing. This leads to cost savings and improved operational performance.

2. Environmental Compliance As industries face increasing pressure to adhere to environmental regulations, OEM Anionic PAM can be tailored to help meet these standards. Efficient flocculation and sedimentation reduce the amount of chemicals needed, minimizing environmental impact.

3. Versatility The versatility of Anionic Polyacrylamide allows it to be used in various industrial sectors. OEM suppliers can develop products that cater to specific needs, ensuring that manufacturers have access to the right solutions for their applications.

4. Consistency and Quality Working with OEM suppliers ensures a level of consistency and quality in the final product. Manufacturers benefit from reliable performance and predictable outcomes, essential for maintaining operational standards.

Conclusion

In conclusion, OEM Anionic Polyacrylamide plays a vital role in numerous industrial applications, providing customized solutions that enhance efficiency, environmental compliance, and overall product performance. As industries continue to evolve, the demand for specialized chemical solutions like Anionic PAM will only grow, making it an essential component in the toolkit of modern manufacturers. By harnessing the power of OEM Anionic Polyacrylamide, industries can thrive in a competitive landscape, ensuring sustainable growth and innovation.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025