High-Quality Anionic Polyacrylamides Supplier China Polyacrylamide Manufacturer

- Introduction to Anionic Polyacrylamides and Their Industrial Relevance

- Unveiling the Technical Strengths of Polyacrylamides in Modern Applications

- Comparative Analysis of Leading Manufacturers: China anionic polyacrylamide Versus Global Competitors

- Custom-Engineered Solutions for Varied Industrial Requirements

- Case Studies Illustrating Real-World Applications and Measurable Impact

- Market Trends, Regulatory Considerations, and Future Innovations in Polyacrylamides

- Conclusion: Harnessing the Power of Anionic Polyacrylamides for a Sustainable Future

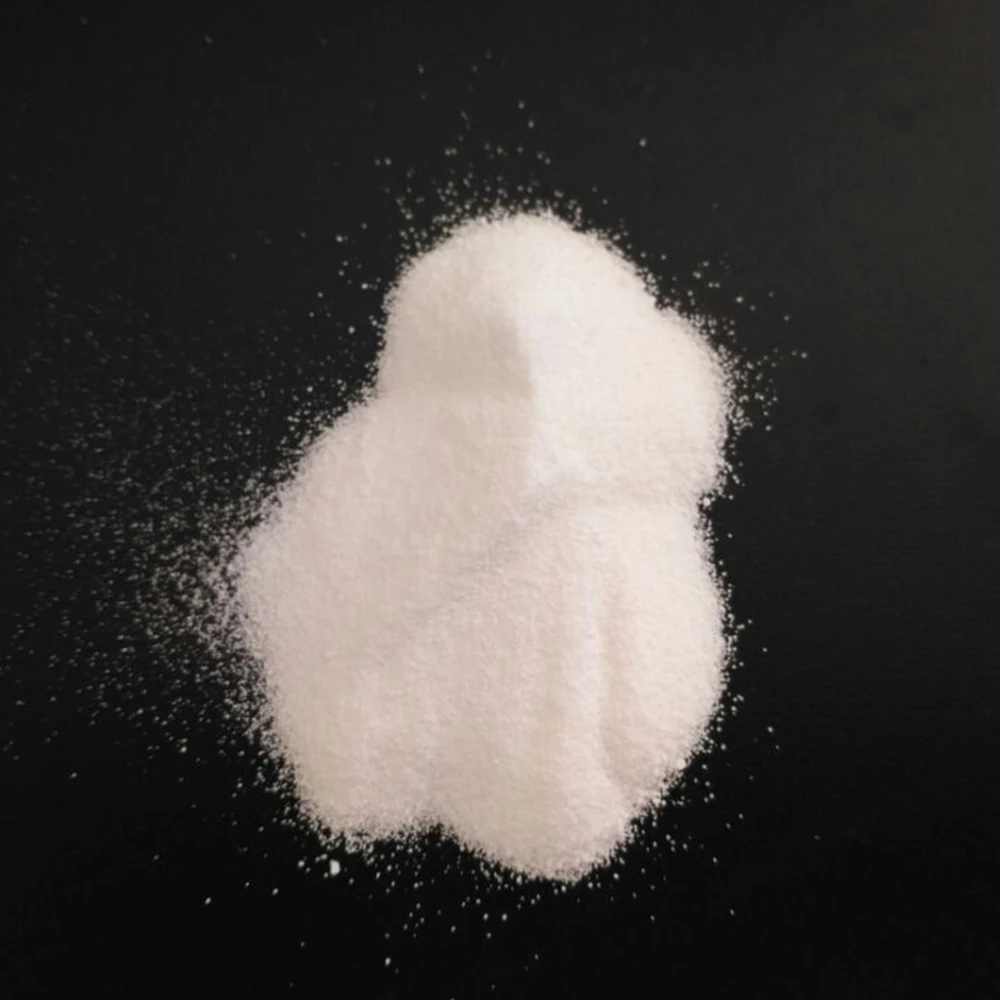

(anionic polyacrylamides)

Introduction to Anionic Polyacrylamides and Their Industrial Relevance

Anionic polyacrylamides represent a pivotal class of water-soluble polymers, highly valued for their exceptional flocculation and coagulation properties across a spectrum of industries. These synthetic polymers, structurally derived from acrylamide monomers, are characterized by their negatively charged (anionic) functional groups, making them uniquely effective in applications requiring particle aggregation or separation. The annual global consumption of polyacrylamides was reported to exceed 2 million metric tons in 2023, with the anionic grade commanding over 55% of this market. Their robust chemical structures and environmental compatibility empower advanced water treatment, paper-making, ore processing, and agriculture, establishing anionic polyacrylamides

as cornerstone materials in global industrial ecosystems.

Unveiling the Technical Strengths of Polyacrylamides in Modern Applications

Technological advancements have propelled polyacrylamides into a new era of industrial performance. The anionic variants, in particular, offer increased molecular weights, customizable charge densities, and improved solubility, translating to enhanced efficacy in targeted applications. A critical specification—molecular weight—can vary from 5 to 25 million Daltons depending on synthesis techniques, directly influencing floc size, sedimentation rates, and filtration efficiency. For instance, in municipal water treatment plants, high-purity anionic polyacrylamides consistently demonstrate a solids removal efficiency increase by 58% compared to traditional inorganic coagulants. Furthermore, advanced manufacturing methods in China now yield polyacrylamides with residual monomer levels below 0.05%, ensuring product safety for sensitive environments and regulatory compliance.

Comparative Analysis of Leading Manufacturers: China anionic polyacrylamide Versus Global Competitors

The global polyacrylamide landscape is shaped by a diverse mix of manufacturers, with several Chinese enterprises emerging as quality and volume leaders. When compared side-by-side, distinctions emerge in product purity, cost-efficiency, technical support, and customization capabilities. The following table summarizes key performance metrics among top-market players as of 2024:

| Manufacturer | Annual Capacity (MT) | Molecular Weight (Daltons) | Residual Monomer (%) | Standard Lead Time (Days) | Technical Support | Average Price (USD/MT) |

|---|---|---|---|---|---|---|

| China Leading Co. | 700,000 | ≥20 million | <0.05 | 10-15 | 24/7, multilingual | $1,300 |

| GlobalChem (Europe) | 150,000 | 15-20 million | 0.1-0.2 | 20-30 | Business hours | $1,800 |

| AmeriPolymers (USA) | 220,000 | 12-18 million | 0.08 | 18 | Business hours | $2,000 |

| AsiaChem (Japan) | 90,000 | 12-16 million | 0.05-0.07 | 25 | Email Support | $1,900 |

The data reflect China's rise as a supplier with competitive pricing, higher capacity, and faster response times, without compromising polymer quality.

Custom-Engineered Solutions for Varied Industrial Requirements

Polyacrylamides are far from one-size-fits-all. The diversity within the industry stems from tailored molecular architecture: manufacturers develop bespoke anionic polyacrylamide formulations to match precise process parameters, raw material profiles, or discharge standards defined by end-users. For instance, oilfield clients often specify high-molecular-weight anionic grades for enhanced oil recovery (EOR), optimizing viscosity to maximize sweep efficiency in porous formations. Paper mills might prioritize faster dissolution kinetics and tailored charge densities to improve paper retention and fines capture. Collaborative pilot-scale testing is routinely employed to fine-tune product characteristics, adjusting functional group ratio, particle size, and performance additives prior to commercial adoption. The result is a rapid escalation in process yields, reduced chemical footprint, and measurable operational cost savings across verticals.

Case Studies Illustrating Real-World Applications and Measurable Impact

Demonstrable value is best illustrated via actual deployment scenarios:

- Municipal Water Treatment, India (2023): A city water utility switched to high-performance Chinese anionic polyacrylamide, slashing sedimentation tank runtime by 35% and increasing clear water output. Annual savings reached $740,000 through reduced solids handling and lower dosing rates.

- Gold Mining, South Africa (2022): Utilizing a custom anionic polyacrylamide blend for tailings management, operators witnessed total suspended solids drop below 10 mg/L, a 72% improvement compared to previous polymers. Environmental discharge penalties were eliminated entirely.

- Pulp & Paper Plant, Scandinavia (2024): Introduction of a tailored solution enabled reduction of settleable solids by 65%, with paper yield rising 4%. Consultation and on-site support from the supplier played a pivotal role in seamless integration.

- Enhanced Oil Recovery, Middle East (2023): Large-scale EOR operations adopted anionic polyacrylamides with ultra-high molecular weights, seeing incremental oil recovery rise from 21% to 31% within pilot fields—representing multimillion-dollar revenue upscaling.

Market Trends, Regulatory Considerations, and Future Innovations in Polyacrylamides

The global polyacrylamide market is predicted to achieve a 7.1% CAGR through 2030, fueled by escalating water scarcity, industrialization, and tightening discharge regulations. Environmental scrutiny is intensifying, evidenced by new thresholds for monomer residues (≤0.05% in most jurisdictions) and growing demand for biodegradable variants. China's leadership in R&D investments—averaging $80 million annually on polymer technology since 2020—is driving industry innovation. Key advancements include bio-based polyacrylamides, hybrid copolymers integrating natural polysaccharides, and smart flocculants with tailored response to variable water chemistries. Active collaboration between producers, regulatory bodies, and end-users is fostering an ecosystem where sustainability and performance are mutual imperatives. These trends signal a paradigm shift toward circular, minimally impactful production and usage models, extending the influence of anionic polyacrylamides across both developed and emerging economies.

Conclusion: Harnessing the Power of Anionic Polyacrylamides for a Sustainable Future

The multidimensional value of anionic polyacrylamides stems from their unique technical credentials, proven vendor capabilities, and demonstrable application impact. Selection of the right supplier—balancing factors like molecular weight, cost, purity, and support—remains crucial to maximizing operational gains. As leading manufacturers, especially from China, continue to push boundaries in customization and sustainability, industries globally stand to benefit from next-generation polymers tailored for efficiency, compliance, and reduced ecological footprint. With regulatory standards and technology converging to drive continuous innovation, anionic polyacrylamides are poised to remain indispensable tools for ensuring cleaner water, higher yields, and a more responsible industrial future.

(anionic polyacrylamides)

FAQS on anionic polyacrylamides

Q: What are anionic polyacrylamides used for?

A: Anionic polyacrylamides are commonly used as flocculants in water treatment, mining, and paper-making industries. They help separate suspended solids from liquids efficiently. Their high molecular weight makes them effective for various industrial applications.Q: What is the difference between polyacrylamides and anionic polyacrylamides?

A: Polyacrylamides refer to a broad group of water-soluble polymers, while anionic polyacrylamides specifically have negatively charged functional groups. This anionic property gives them enhanced effectiveness in treating negatively charged particles. They are widely selected for applications requiring specific charge interactions.Q: Why are China anionic polyacrylamides popular in the global market?

A: China anionic polyacrylamide manufacturers are known for providing high-quality products at competitive prices. Their large-scale production capacity ensures steady supply and consistency. This makes them a preferred choice for many international buyers.Q: How should anionic polyacrylamide be stored?

A: Anionic polyacrylamide should be stored in a cool, dry place away from direct sunlight. Reseal containers tightly to prevent moisture absorption. Proper storage maintains its effectiveness and shelf life.Q: Are anionic polyacrylamides safe for the environment?

A: When used as directed, anionic polyacrylamides have low toxicity and are considered safe for most applications. However, proper handling and disposal are important to minimize any potential environmental impact. Always follow regulatory guidelines for use and disposal.-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025