Using Caustic Soda for Soap Production and Crafting Natural Skincare Products

The Role of Caustic Soda in Soap Making

Soap making is an ancient craft that has evolved over thousands of years. At its core, the process involves a chemical reaction known as saponification, where fats or oils combine with an alkali to produce soap. One of the most common alkalis used in soap making is caustic soda, also known as sodium hydroxide (NaOH). This article explores the importance of caustic soda in soap production, its properties, safety considerations, and tips for its use in home soap making.

What is Caustic Soda?

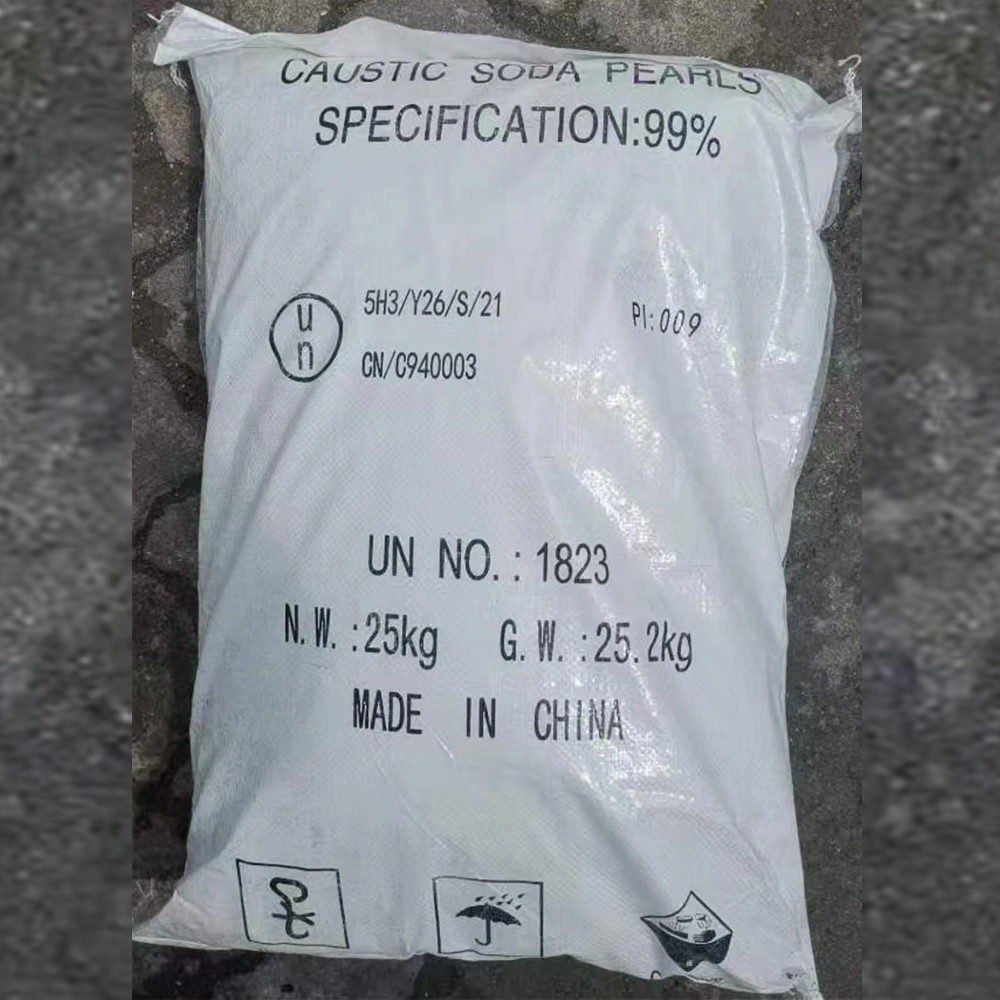

Caustic soda is a strong alkaline compound that appears as a white solid, typically in granular or flaked form. It is highly soluble in water, generating a significant amount of heat upon dissolution. A key characteristic of caustic soda is its ability to break down fats and oils, making it an essential ingredient in the soap making process. When mixed with water, it forms a lye solution, which acts as the catalyst for saponification.

The Saponification Process

The saponification process involves the chemical reaction between fats or oils and an alkali. When caustic soda is combined with these lipids, it breaks them down into fatty acids and glycerol, leading to the formation of soap. The general formula for this reaction can be summarized as follows

\[ \text{Fat/oil} + \text{NaOH} \rightarrow \text{Soap} + \text{Glycerin} \]

The resulting soap can vary in characteristics such as hardness, lathering ability, and moisturizing properties, depending on the type of fats or oils used. Common oils for soap making include olive oil, coconut oil, and palm oil, each imparting unique qualities to the final product.

Safety Considerations

While caustic soda is a powerful soap making ingredient, it is also highly caustic and can pose safety risks if not handled properly

. Here are some safety guidelines to follow when using caustic soda1. Protective Gear Always wear protective gloves, goggles, and long sleeves to prevent skin and eye irritation. Caustic soda can cause severe burns upon contact with skin.

caustic soda for soap making

2. Ventilation Work in a well-ventilated area to minimize inhalation of fumes generated during the lye mixing process, as sodium hydroxide can release harmful vapors.

3. Storage Store caustic soda in a cool, dry place, away from children and pets, and in a securely closed container to prevent spills and accidental ingestion.

4. Measuring and Mixing Use precise measurements when combining caustic soda with water. Never add water to caustic soda, as it can cause a violent reaction. Always add caustic soda slowly to water to ensure safety.

Tips for Successful Soap Making

For those looking to venture into home soap making with caustic soda, here are a few tips to achieve the best results

1. Use a reliable recipe Follow a tested soap recipe that includes specific measurements for both the lye and oils. This helps ensure that you achieve proper saponification and a balanced product.

2. Track temperatures Monitor the temperature of both the lye solution and oils. A range between 95°F to 110°F is typically ideal for mixing.

3. Embrace creativity Once you are comfortable with the basics, experiment with different oils, fragrances, and colorants to create custom soaps that suit your preferences.

4. Curing time After molding, allow your soap to cure for at least 4-6 weeks. This not only improves the soap’s hardness and lathering properties but also reduces excess lye, resulting in a milder product.

Conclusion

Caustic soda plays a pivotal role in the art of soap making, enabling the transformation of oils and fats into the luxurious bars we use today. While its handling requires caution, the rewards of creating personalized, handmade soap are well worth the effort. By understanding the saponification process, adhering to safety measures, and being innovative with recipes, anyone can embark on a fulfilling soap making journey. Whether for personal use or as gifts, handmade soap crafted with care and precision stands as a testament to both science and artistry.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025