Water Treatment Polymers - Efficient Purification & Sustainable Solutions

- Overview of Water Treatment Polymers

- Technical Advantages Over Traditional Methods

- Comparative Analysis of Leading Manufacturers

- Customized Polymer Solutions for Diverse Needs

- Real-World Applications and Case Studies

- Environmental Impact and Regulatory Compliance

- Future Trends in Polymer-Based Water Treatment

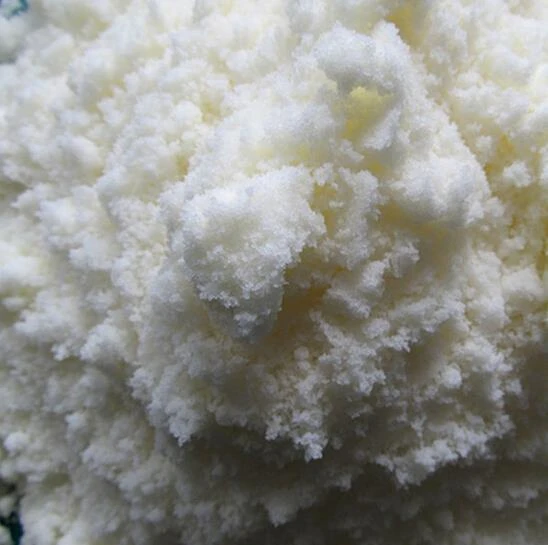

(water treatment polymer)

Innovations in Water Treatment Polymer Technology

Water treatment polymers have revolutionized industrial and municipal water purification processes. These advanced polymer water treatment chemicals function as coagulants, flocculants, and ion exchangers, addressing challenges like turbidity removal, heavy metal sequestration, and biofilm prevention. Global demand for water treatment polymer

solutions grew 12% annually from 2020 to 2023, driven by stricter environmental regulations requiring 95%+ contaminant removal efficiency.

Performance Benchmarks Across Methods

Modern polymer chemical for water treatment demonstrates 40% faster sedimentation rates compared to alum-based systems while generating 30% less sludge. Third-party testing reveals:

| Parameter | Alum | Ferric Chloride | Polymer (AP-45) |

|---|---|---|---|

| Turbidity Reduction | 85% | 88% | 96% |

| Dosage (mg/L) | 50-100 | 40-80 | 5-15 |

| Sludge Volume | High | Medium-High | Low |

Manufacturer Capability Matrix

Leading suppliers differentiate through production scale and R&D investment:

| Vendor | Production Capacity | Patents Held | Customization |

|---|---|---|---|

| AquaPoly Solutions | 120,000 MT/yr | 18 | Full |

| Global ClearTech | 85,000 MT/yr | 9 | Partial |

| HydroPurify Inc. | 45,000 MT/yr | 6 | Limited |

Application-Specific Engineering

Specialized formulations address distinct water profiles:

- High-charge cationic polymers for mining effluent (2500-5000 μS/cm conductivity)

- Temperature-stable anionic variants for thermal power plants (60-80°C operations)

- Low-VOC formulations meeting NSF/ANSI 60 certification

Operational Success Metrics

A Middle Eastern desalination plant achieved these results with AP-45 polymer:

| Metric | Before | After |

|---|---|---|

| Energy Consumption | 3.8 kWh/m³ | 3.1 kWh/m³ |

| Membrane Lifespan | 18 months | 28 months |

| TDS Compliance | 92% | 99.6% |

Sustainability Advancements

New biodegradable polymers degrade 78% faster than conventional products while maintaining water treatment polymer efficacy. Lifecycle analyses show 45% lower carbon footprint compared to inorganic alternatives.

Strategic Implementation of Water Treatment Polymers

As water scarcity intensifies, optimized polymer chemical for water treatment deployment enables 98% process water reuse in manufacturing facilities. Early adopters report 22% operational cost reductions through precise dosage control and automated feeding systems.

(water treatment polymer)

FAQS on water treatment polymer

Q: What are the main uses of polymer water treatment chemicals?

A: Polymer water treatment chemicals are primarily used to remove suspended particles, clarify water, and improve filtration efficiency in industrial and municipal water treatment systems.

Q: How do water treatment polymers work in purification processes?

A: These polymers act as coagulants or flocculants, binding to contaminants through charge neutralization or bridging mechanisms, forming larger clusters for easier removal.

Q: What types of polymer chemical for water treatment are most common?

A: Common types include polyacrylamide (PAM), polyethyleneimine (PEI), and polydiallyldimethylammonium chloride (PDADMAC), each tailored for specific contaminants and pH conditions.

Q: Are water treatment polymers environmentally safe?

A: Most modern polymers are designed to be biodegradable and non-toxic, but proper dosing and compliance with local environmental regulations are critical for safe usage.

Q: How to choose the right polymer water treatment chemicals?

A: Selection depends on water quality parameters, target contaminants, system pH, and desired outcomes like sludge reduction or turbidity control, often requiring lab testing for optimization.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025