boiler water chemistry pdf

Understanding Boiler Water Chemistry Essential for Efficient Boiler Operation

Boiler water chemistry plays a crucial role in the efficient and safe operation of steam generation systems. Properly managing boiler water quality can prevent various operational problems, including corrosion, scaling, and other issues that can lead to costly downtimes or equipment failures. This article outlines the key aspects of boiler water chemistry and the importance of monitoring and controlling various parameters.

1. Importance of Boiler Water Chemistry

Boilers are critical components in various industries, including power generation, manufacturing, and food processing. The water used in boilers must be carefully treated to ensure that it does not contribute to problems such as scaling, corrosion, and foaming. The primary objectives of maintaining good boiler water chemistry include

- Preventing Corrosion The fundamentals of boiler water chemistry lie in minimizing the potential for corrosion of boiler components. Corrosive agents like dissolved oxygen, carbon dioxide, and chloride ions can significantly damage boiler tubes and other structural components.

- Controlling Scale Formation Hardness minerals such as calcium and magnesium can precipitate and form scale on the heat transfer surfaces of the boiler. This scale acts as an insulator, reducing heat transfer efficiency and leading to overheating and potential failure of boiler tubes.

- Avoiding Foaming and Priming Proper chemical treatment helps control the surface tension of water. Foaming and priming can occur when dissolved solids accumulate, leading to the carryover of water into the steam system, which can cause damage to turbines and other downstream equipment.

2. Key Parameters in Boiler Water Chemistry

The chemistry of boiler water is a complex topic that involves various parameters that need to be monitored and controlled

- pH Levels Maintaining the correct pH level is critical for preventing corrosion. Ideally, boiler water should be kept alkaline, with a pH ranging from 9.5 to 11.5. This alkaline condition minimizes the solubility of corrosive ions.

- Conductivity Conductivity is directly related to the concentration of dissolved solids in the water. High conductivity indicates a high level of impurities, which can be detrimental to boiler operation. Regular measurement and maintenance of conductivity levels are vital.

boiler water chemistry pdf

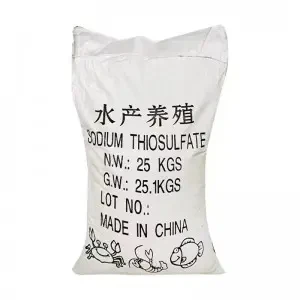

- Dissolved Oxygen Oxygen is one of the primary contributors to corrosion in boiler systems. Effective oxygen scavengers, such as sodium sulfite or hydrazine, are often used to remove dissolved oxygen from the water.

- Total Dissolved Solids (TDS) TDS measurements indicate the total concentration of dissolved ions, salts, and minerals. High TDS can lead to scaling and other issues, thus regular blowdown procedures are necessary to manage TDS levels effectively.

- Alkalinity Maintaining appropriate levels of alkalinity is crucial for corrosion prevention and control of scaling. The two primary anions contributing to alkalinity are bicarbonate and carbonate ions.

3. Chemical Treatment Programs

To address the challenges posed by poor boiler water chemistry, many facilities implement systematic chemical treatment programs. These programs typically include

- Oxygen Scavengers To reduce dissolved oxygen levels, compounds such as sodium sulfite, hydrazine, or other oxygen scavengers are routinely added to the boiler water.

- Scale Inhibitors Chemicals such as polyacrylates or phosphonates are employed to prevent scale formation by dispersing particles and maintaining them in a colloidal suspension.

- Corrosion Inhibitors Various chemicals can protect against corrosion, often by forming a protective film on metal surfaces.

Conclusion

In conclusion, understanding and managing boiler water chemistry is essential for efficient and safe boiler operation. By controlling key parameters such as pH, conductivity, dissolved oxygen, and TDS, operators can prevent corrosion, scaling, and other operational issues. Implementing a comprehensive chemical treatment program ensures the longevity and reliability of boiler systems, ultimately leading to improved performance and reduced operational costs. Attention to these critical aspects of boiler water chemistry will help industries maintain optimal functionality while minimizing risks associated with boiler operation.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025