Creating Sodium Chlorate Using Household Bleach Efficiently and Safely

How to Make Sodium Chlorate from Bleach

Sodium chlorate (NaClO₃) is a powerful chemical compound widely used in herbicides, explosives, and as a bleaching agent in the paper industry. One of the common methods to produce sodium chlorate involves the electrolysis of sodium chloride (table salt) solutions. Bleach, primarily composed of sodium hypochlorite (NaClO), can be converted into sodium chlorate through a controlled electrolysis process. This article will outline the steps involved, precautions to take, and the chemistry behind this conversion.

Understanding the Chemistry

Before diving into the process, it’s essential to comprehend the chemical transformations at play. When sodium hypochlorite is subjected to an electrolysis process, it undergoes oxidation to form sodium chlorate. The general reactions can be summarized as follows

1. Oxidation of Hypochlorite \[ 3 NaClO \rightarrow NaClO_3 + 2 NaCl + 2 e^- \]

In this reaction, three moles of sodium hypochlorite yield one mole of sodium chlorate and two moles of sodium chloride after releasing electrons during the electrolysis process.

Materials Needed

To perform this process, you will need the following materials

- Household bleach (sodium hypochlorite solution, typically at 5-10% concentration) - A power source (DC power supply) - Electrolysis cell (can be made from a non-reactive container) - Electrodes (preferably made from inert materials like titanium or graphite) - Distilled water - pH indicator (optional) - Protective gear (gloves, goggles, mask)

Step-by-Step Process

1. Preparation of the Electrolysis Cell Make sure your electrolysis cell is clean and made of non-reactive materials. Fill the container with a solution of bleach and distilled water. A dilution of approximately 1 part bleach to 3 parts water is often effective.

how to make sodium chlorate from bleach

2. Submerging the Electrodes Insert your electrodes into the solution, ensuring they do not touch each other. The anode (positive electrode) will need to be of a material that withstands chlorine gas release, while the cathode (negative electrode) can be a different inert material.

3. Setting up the Power Supply Connect your power supply to the electrodes. Start with a low voltage; about 6-12 volts is typically sufficient for the process. Monitor the current; it should generally stay below the recommended threshold for your setup.

4. Monitoring the Reaction As the electrolysis proceeds, you may see bubbling or gas release, primarily chlorine gas from the anode. It’s crucial to conduct this process in a well-ventilated area or under a fume hood to prevent accumulation of toxic gases.

5. Adjusting pH Throughout the process, monitor the pH of the solution. Sodium hypochlorite solutions can decompose at higher pH levels, and maintaining a pH level around neutral will help stabilize the process. You can adjust pH by adding small amounts of diluted hydrochloric acid or sodium hydroxide.

6. Completion and Extraction The electrolysis may take several hours, depending on the concentration of your starting solution and the applied current. Once the process seems complete (when no more bubbling is observed), you can stop the power supply. The resulting solution should contain sodium chlorate.

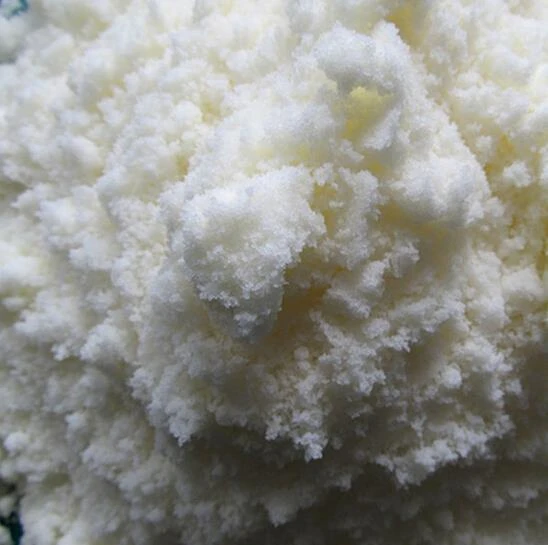

7. Crystallization To obtain solid sodium chlorate, evaporate the excess water gently and allow the solution to cool. Crystals of sodium chlorate will form as the solution concentration increases.

Safety Precautions

Working with chemicals always requires caution. Ensure you wear protective gear, including gloves, goggles, and a mask, as sodium hypochlorite and chlorine gas can be harmful. Conduct the process in a well-ventilated area to avoid inhaling toxic fumes. Dispose of any chemical waste according to local regulations.

Conclusion

In summary, making sodium chlorate from bleach is a relatively straightforward process, combining basic chemistry and electrolysis techniques. While it can be performed safely at home, extreme care should be exercised due to the hazardous materials involved. This method not only highlights the fascinating transformations of chemicals but also encourages a hands-on approach to learning about chemical processes. Always prioritize safety and environmental considerations when engaging in chemical experiments.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025