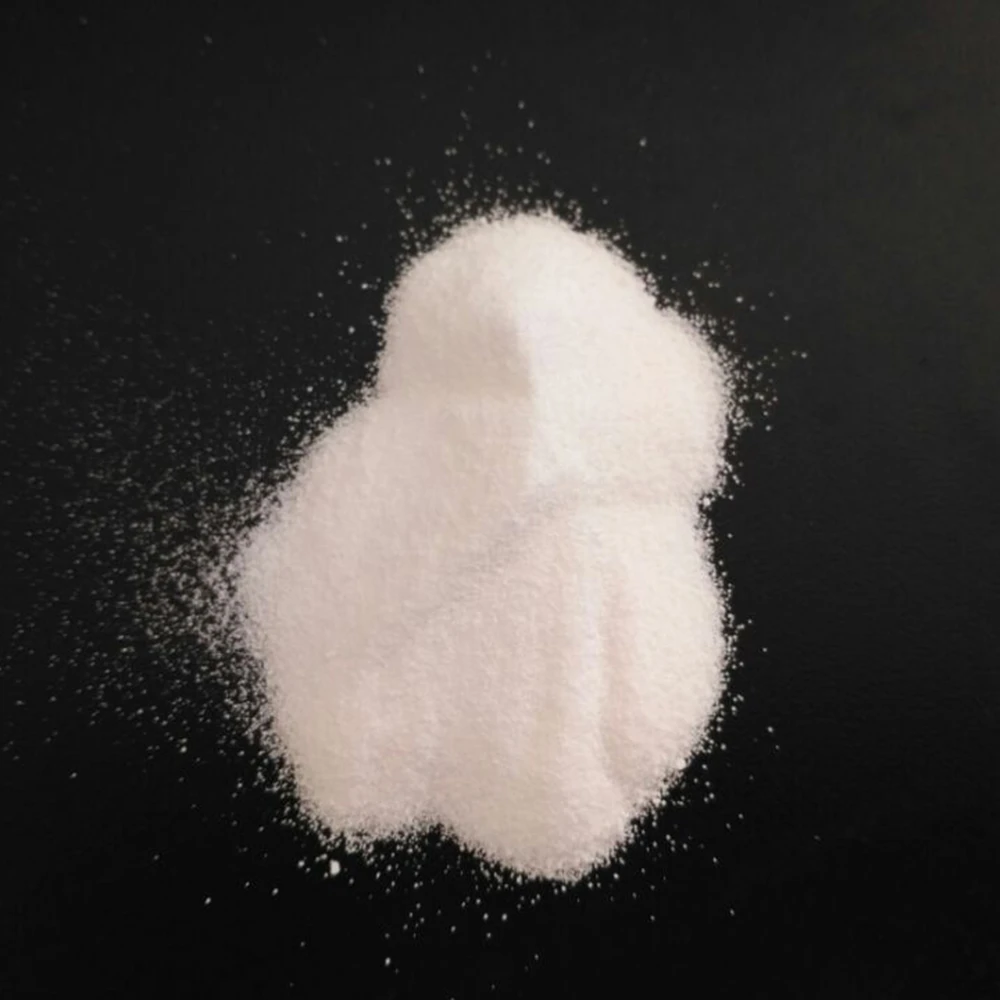

Potassium Amyl Xanthate 90% for Gold Flotation Efficiency

Feb . 01, 2025 05:47

Back to list

Potassium Amyl Xanthate 90% for Gold Flotation Efficiency

Effluent Treatment Plants (ETPs) play a vital role in treating industrial wastewater, removing harmful contaminants before discharge into the environment. These facilities use a range of chemicals to ensure wastewater meets regulatory standards, protecting both ecological and human health. Understanding these chemicals, how they work, and their efficiency is fundamental for industries aiming to implement a reliable ETP system.

Neutralization chemicals, such as hydrochloric acid or sodium hydroxide, are employed to adjust pH levels to optimal ranges for effective treatment processes and regulatory compliance. Proper pH balance ensures the efficiency of biological treatment stages and protects equipment from corrosive damage. For industries dealing with odorous compounds or color pollutants, active carbon and specialized polymers are common additions to the ETP regime. Activated carbon is particularly effective in adsorbing color and binding volatile organic compounds (VOCs) responsible for unpleasant smells. Meanwhile, specialty polymers can enhance the removal of color, optimizing the aesthetics of the output water to meet stringent discharge standards. In ensuring the operational excellence of ETPs, regular monitoring with indicators like Total Suspended Solids (TSS), COD, and pH is indispensable for verifying treatment efficiency. Maintaining the right chemical balance is a delicate task that requires expertise and continual evaluation to adapt to variations in wastewater composition. By employing a tailored combination of these chemicals and processes, industries can achieve compliance with environmental regulations while minimizing their ecological footprint. Not only does this demonstrate corporate responsibility, but it also fortifies community relations and reputational standing. In an era where sustainable practices are more critical than ever, understanding and leveraging the full capabilities of ETPs is a vital step towards a greener industrial landscape.

Neutralization chemicals, such as hydrochloric acid or sodium hydroxide, are employed to adjust pH levels to optimal ranges for effective treatment processes and regulatory compliance. Proper pH balance ensures the efficiency of biological treatment stages and protects equipment from corrosive damage. For industries dealing with odorous compounds or color pollutants, active carbon and specialized polymers are common additions to the ETP regime. Activated carbon is particularly effective in adsorbing color and binding volatile organic compounds (VOCs) responsible for unpleasant smells. Meanwhile, specialty polymers can enhance the removal of color, optimizing the aesthetics of the output water to meet stringent discharge standards. In ensuring the operational excellence of ETPs, regular monitoring with indicators like Total Suspended Solids (TSS), COD, and pH is indispensable for verifying treatment efficiency. Maintaining the right chemical balance is a delicate task that requires expertise and continual evaluation to adapt to variations in wastewater composition. By employing a tailored combination of these chemicals and processes, industries can achieve compliance with environmental regulations while minimizing their ecological footprint. Not only does this demonstrate corporate responsibility, but it also fortifies community relations and reputational standing. In an era where sustainable practices are more critical than ever, understanding and leveraging the full capabilities of ETPs is a vital step towards a greener industrial landscape.

Latest news

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025