Safety Data Sheet for 10% Sodium Hydroxide Solution Handling and Precautions

Understanding the Safety Data Sheet (SDS) for 10% Sodium Hydroxide (NaOH)

Sodium hydroxide (NaOH), commonly known as caustic soda or lye, is a highly versatile chemical used extensively across various industries, including chemical manufacturing, food processing, and water treatment. When dealing with such a hazardous substance, it is critical to understand the Safety Data Sheet (SDS) that accompanies it. This document provides vital information regarding the handling, storage, and potential hazards of sodium hydroxide, particularly in its 10% concentration form.

1. Chemical Identification and Composition

10% sodium hydroxide is an aqueous solution containing 10% sodium hydroxide by weight, with the remainder being water. In the SDS, the chemical formula is designated as NaOH, and it is important to note the presence of potential impurities, which could influence safety measures. The first section of an SDS typically includes details like the product name, manufacturer, contact information, and emergency telephone numbers.

2. Hazards Identification

The hazards associated with 10% NaOH are significant. Sodium hydroxide is classified as a corrosive substance and can cause severe burns upon contact with skin or eyes. Inhalation of mists or vapors can also pose respiratory risks. The SDS outlines these hazards clearly, typically using GHS (Globally Harmonized System) classifications. Understanding these hazards is crucial for anyone working with or around this chemical.

Should exposure occur, the SDS provides critical first aid measures. For skin contact, immediate removal of contaminated clothing and rinsing the affected area with plenty of water for at least 15 minutes is essential. In the case of eye exposure, a thorough rinsing with water while holding the eyelids open is necessary, followed by immediate medical attention. The SDS also emphasizes the importance of ensuring that appropriate first aid supplies and eyewash stations are available in the workplace.

4. Handling and Storage

Handling 10% sodium hydroxide requires adherence to strict protocols to ensure safety. Workers must use appropriate personal protective equipment (PPE), including gloves, goggles, and face shields, to protect against potential splashes. The SDS recommends strategies like using fume hoods or local exhaust ventilation to minimize inhalation risks.

10 naoh msds

In terms of storage, the SDS advises keeping sodium hydroxide in tightly sealed containers, away from incompatible substances such as strong acids and organic materials. The storage area should be clearly labeled and include appropriate spill containment measures.

5. Exposure Controls and Personal Protection

Personal protective equipment (PPE) is essential when working with 10% sodium hydroxide. The SDS typically outlines the acceptable levels of exposure and suggests using gloves made from materials resistant to corrosion, such as neoprene or rubber. Safety goggles or face shields are also recommended to avoid eye contact. Additionally, any work with sodium hydroxide should take place in a well-ventilated area to reduce inhalation risks.

6. Physical and Chemical Properties

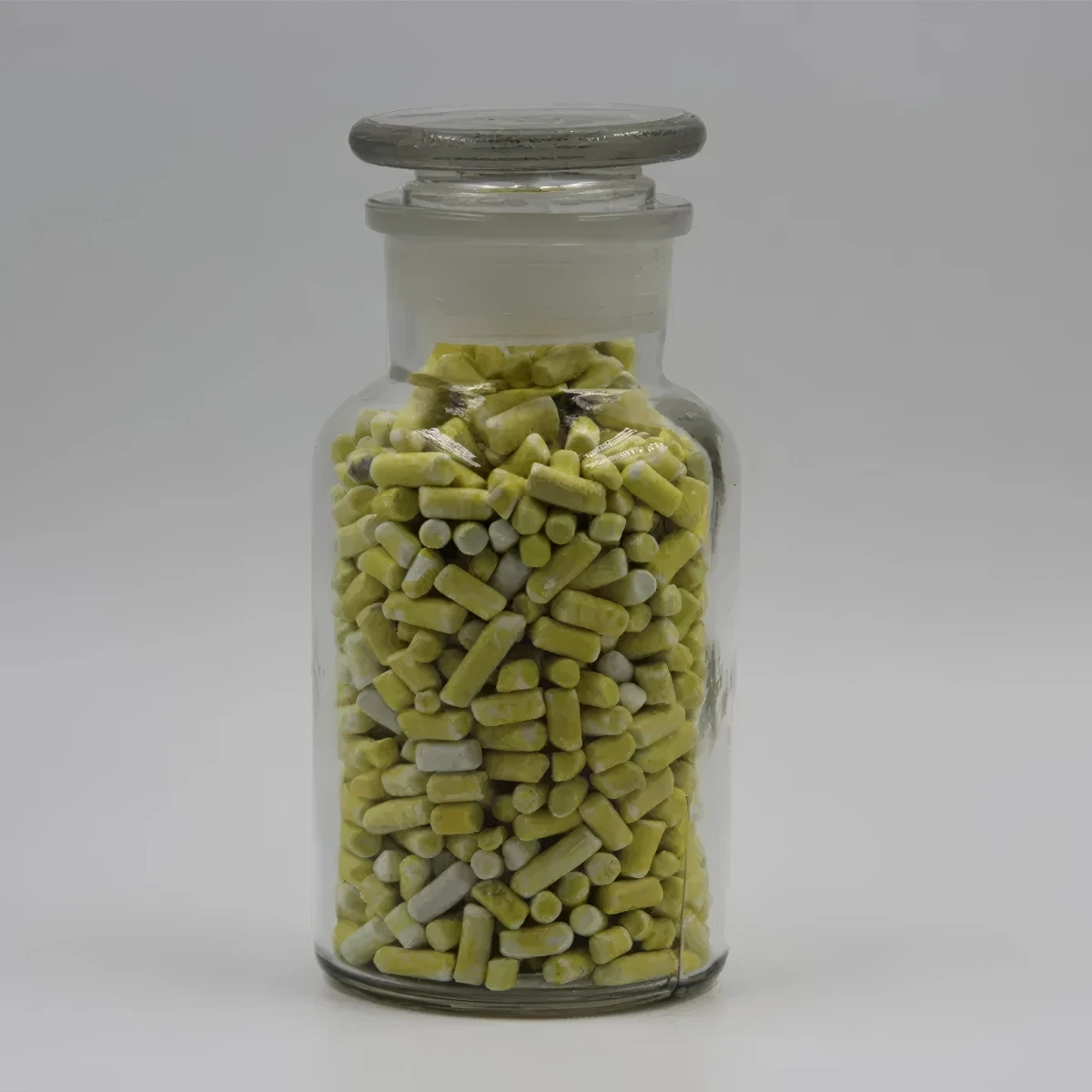

The physical and chemical properties of 10% sodium hydroxide are outlined in detail within the SDS. This includes information on its appearance (often a clear, colorless liquid), pH (highly alkaline), boiling point, and solubility in water. Awareness of these properties helps in understanding the risks associated with leaks or spills.

7. Disposal Considerations

Proper disposal of sodium hydroxide is crucial to minimize environmental impact. The SDS typically provides guidelines for disposal, emphasizing the neutralization of any spent sodium hydroxide before disposal in accordance with local regulations. It is essential to consult these guidelines to prevent environmental contamination.

Conclusion

The Safety Data Sheet for 10% sodium hydroxide is a vital resource for anyone who handles or comes into contact with this chemical. It outlines potential hazards, safety measures, PPE requirements, and first aid procedures. Understanding and adhering to the information within the SDS is crucial for maintaining a safe working environment and preventing accidents. Proper training and awareness are key components in the responsible handling of sodium hydroxide, ultimately ensuring safety for all personnel involved.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025