Mining Products

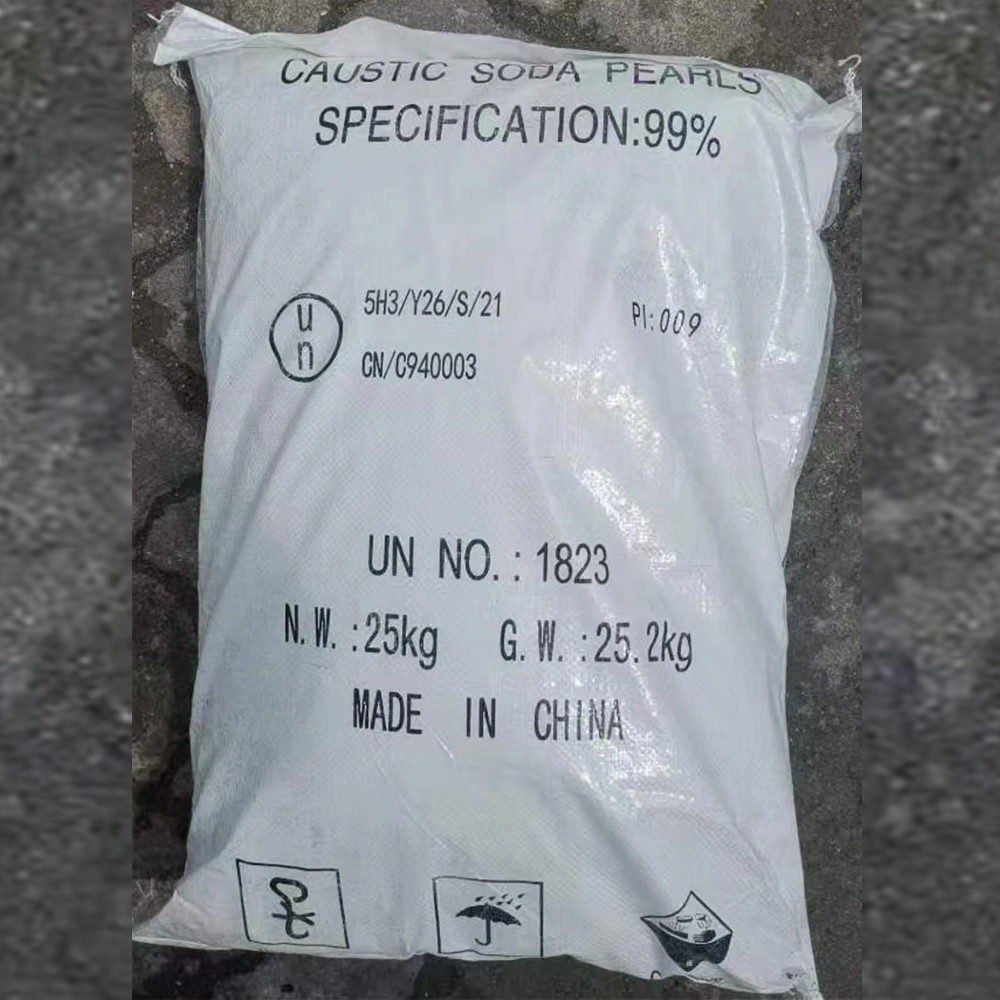

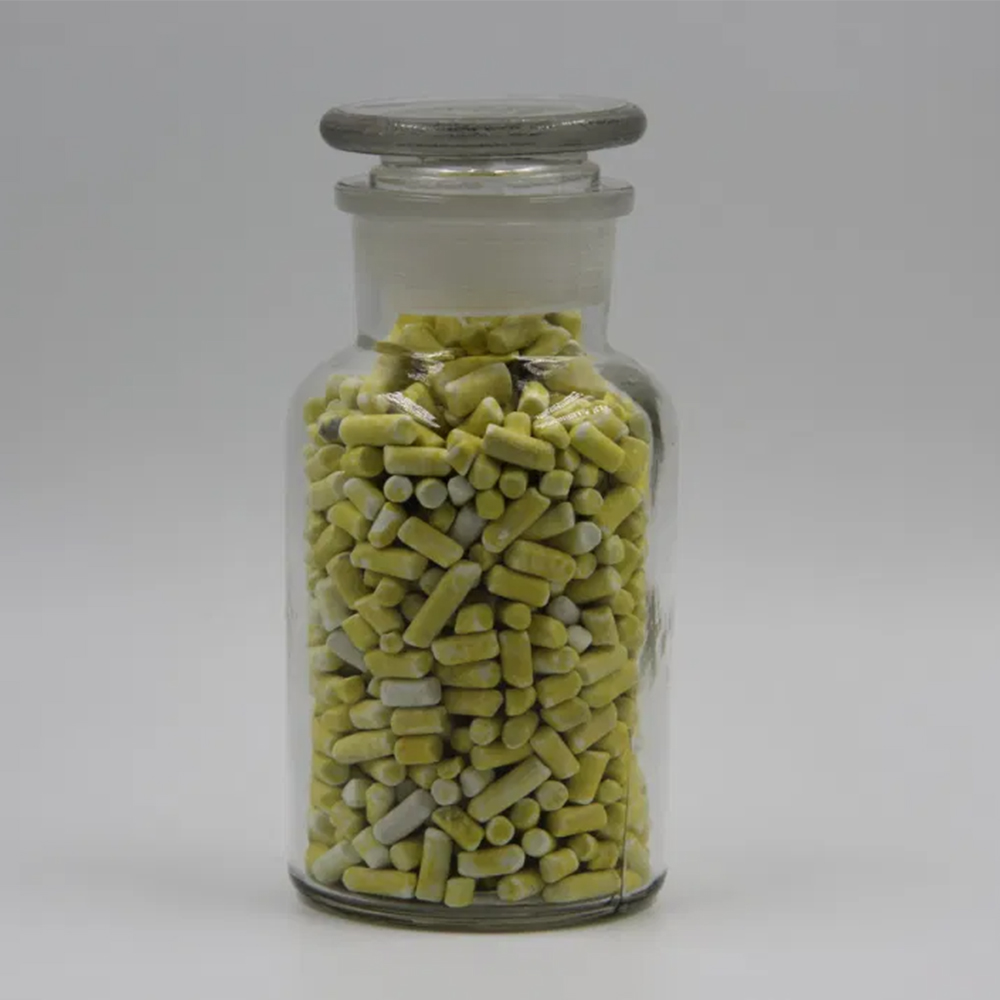

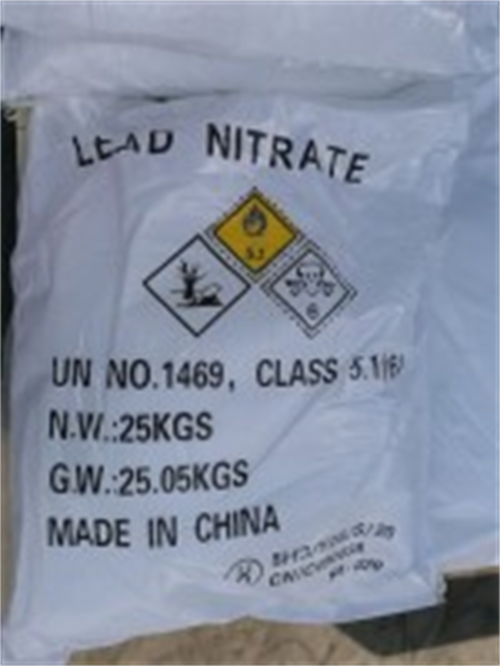

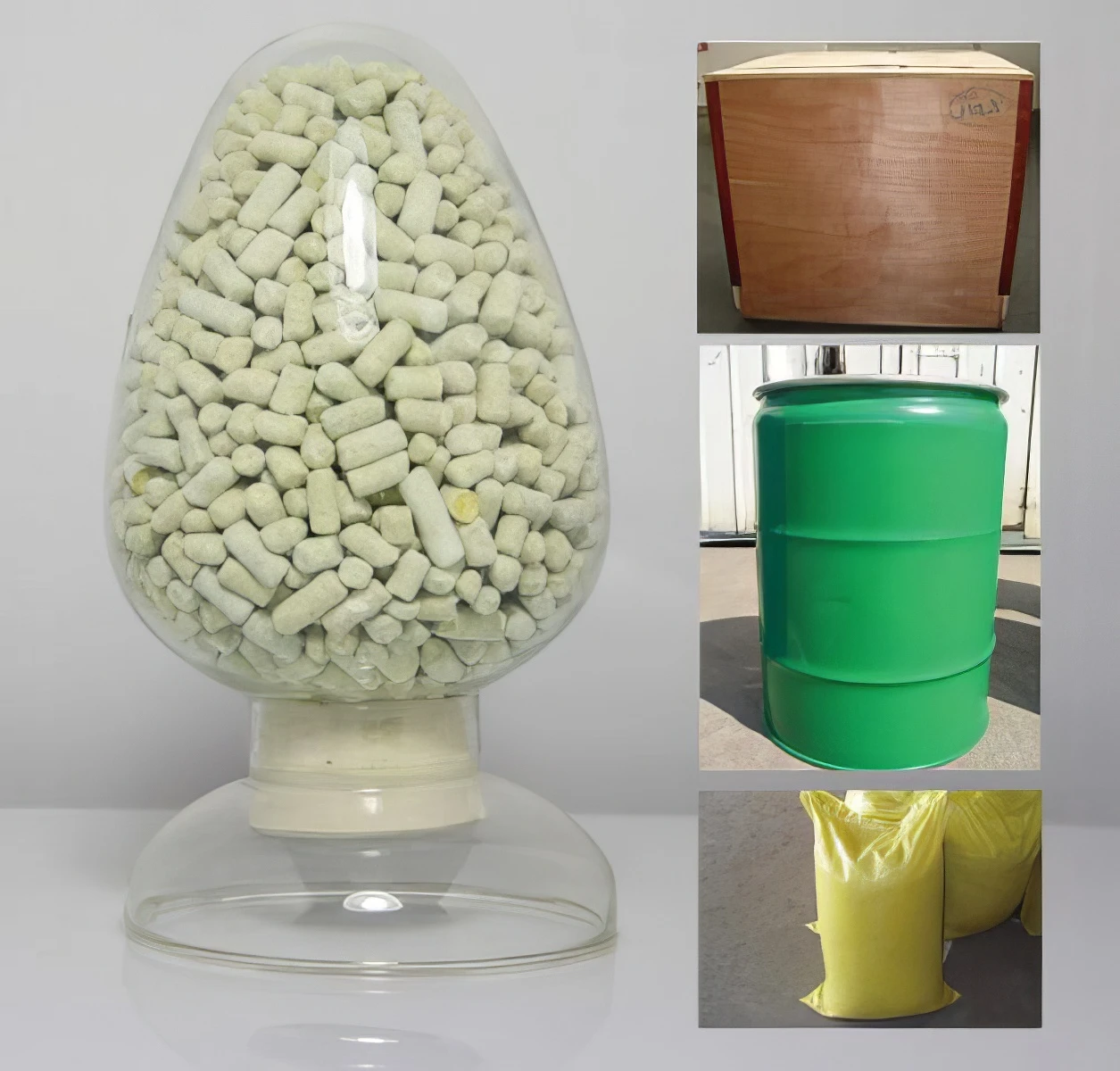

Mining products refer to the equipment, tools, and materials used in the extraction, processing, and transportation of minerals and ores from the earth. These products include heavy machinery like

excavators, drills, and crushers, as well as conveyor belts, safety gear, and chemicals used in mineral processing. Mining products are essential for efficiently and safely extracting valuable resources like coal, gold, iron ore, and other minerals that are crucial for various industries, including construction, manufacturing, and energy production.

What Types Of Equipment Are Commonly Used In Mining Operations?

Common equipment used in mining operations includes drilling rigs, which are used to create boreholes in the earth, and excavators, which are employed to dig and move large quantities of earth and rock. Crushers are used to break down large rocks into smaller, more manageable pieces, while conveyor belts transport materials from one location to another within the mining site. Additionally, personal protective equipment (PPE) like helmets, gloves, and respirators is essential for ensuring the safety of workers in hazardous environments.

How Do Mining Products Contribute To Environmental Sustainability?

Modern mining products are designed with environmental sustainability in mind. Many companies now offer eco-friendly mining equipment that reduces energy consumption, lowers emissions, and minimizes waste. For example, energy-efficient crushers and electric-powered machinery help reduce the carbon footprint of mining operations. Additionally, advanced mineral processing chemicals can improve the efficiency of extraction processes, reducing the amount of waste generated. Properly managed, these products can contribute to more sustainable mining practices, reducing the environmental impact of resource extraction.

What Safety Measures Are In Place For Using Mining Products?

Safety is a top priority in the mining industry, and there are several measures in place to protect workers when using mining products. Equipment is designed to meet rigorous safety standards, including features like reinforced cabs, emergency shut-off systems, and automated controls to prevent accidents. Workers are also provided with PPE, such as helmets, gloves, and respirators, to protect them from physical injuries and exposure to harmful substances. Regular training and safety drills are conducted to ensure that workers are aware of potential hazards and know how to operate equipment safely.