Calcium Ammonium Nitrate Production Process and Techniques Explained

Calcium Ammonium Nitrate Manufacturing Process

Calcium ammonium nitrate (CAN) is a widely used nitrogen fertilizer that plays a crucial role in agricultural productivity. It provides essential nutrients to plants and ensures optimal crop growth. The manufacturing process of calcium ammonium nitrate involves several steps, starting from the reaction of ammonia and nitric acid, leading to the formation of a stable fertilizer product that is easy for farmers to handle and apply.

Step 1 Raw Material Preparation

The primary raw materials required for the production of calcium ammonium nitrate are ammonia, nitric acid, and calcium carbonate (or lime). Ammonia is secured through the Haber-Bosch process, where nitrogen and hydrogen are reacted under high pressure and temperature in the presence of a catalyst. Nitric acid is typically produced by the oxidation of ammonia over a platinum catalyst, resulting in the formation of nitric oxide, which is then oxidized to nitrogen dioxide and absorbed in water. Calcium carbonate or lime is obtained from quarries, where limestone is extracted and processed.

Step 2 Ammonium Nitrate Formation

The first significant reaction in the production of calcium ammonium nitrate is the neutralization of ammonia with nitric acid to form ammonium nitrate (NH4NO3). This reaction can be expressed by the formula

\[ \text{NH}_3 + \text{HNO}_3 \rightarrow \text{NH}_4\text{NO}_3 \]

This process generally takes place in a reactor under controlled conditions to ensure the complete conversion of reactants to products. The ammonium nitrate solution produced in this step is in liquid form, and concentrations can be adjusted based on the desired properties of the final product.

Step 3 Calcium Addition

Following the formation of ammonium nitrate, calcium carbonate or lime is introduced into the process. When calcium carbonate reacts with ammonium nitrate, calcium ammonium nitrate is formed along with the release of carbon dioxide

\[ \text{CaCO}_3 + 2 \text{NH}_4\text{NO}_3 \rightarrow \text{Ca(NH}_4)_2\text{(NO}_3)_2 + \text{CO}_2 + \text{H}_2\text{O} \]

calcium ammonium nitrate manufacturing process

This reaction not only forms the desired product but also helps to moderate the acidity of the solution, providing a more balanced nutrient profile for the plants

.Step 4 Granulation

Once calcium ammonium nitrate is formed, the next step is to convert the solution into a solid form that can be easily stored and distributed. The ammonium nitrate and calcium nitrate mix is typically pumped to a granulation unit, where the solution is sprayed onto small particles of an inert carrier or directly granulated via a drum granulator. The process involves the evaporation of excess moisture, resulting in the formation of solid granules.

Granulation is a critical step, as it affects the fertilizer’s solubility and flow properties, ensuring that it can be easily spread in the field. The granular product is often screened to remove fine particles and ensure uniformity in size.

Step 5 Drying and Packaging

After granulation, the product is further dried to achieve the desired moisture content, which prevents caking and ensures stability during storage. This can be done using fluidized bed dryers or rotary dryers. Once adequately dried, the calcium ammonium nitrate granules are conveyed to the packaging area, where they are bagged in moisture-resistant materials to protect against environmental factors.

Quality Control and Distribution

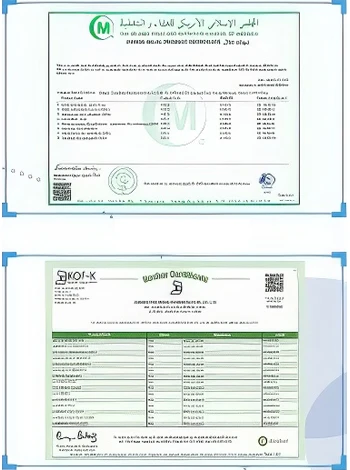

A stringent quality control process is critical throughout the manufacturing of calcium ammonium nitrate. Samples from various stages of production are analyzed for purity, nutrient content, and product stability. Meeting regulatory standards and customer specifications ensures that the fertilizer is safe and effective for agricultural use.

Once the quality has been verified, the packaged product is distributed to retailers and farmers. Calcium ammonium nitrate is favored due to its high nutrient efficiency and ease of application, making it a popular choice for a wide range of crops.

Conclusion

The production of calcium ammonium nitrate is a complex but well-defined process that transforms raw materials into a vital fertilizer for agriculture. With its balanced nutrient content and efficient utilization, it supports farmers in enhancing crop yield and ensuring food security. As agriculture continues to evolve, the demand for efficient fertilizers like CAN will remain crucial in sustainable farming practices.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025