Different Varieties of Caustic Soda and Their Applications in Industry

Understanding the Different Types of Caustic Soda

Caustic soda, also known as sodium hydroxide (NaOH), is a versatile and widely used chemical in various industries. Its strong alkaline properties make it an essential ingredient in many applications, including manufacturing, food processing, and water treatment. This article will delve into the different types of caustic soda, exploring their applications, production methods, and safety considerations.

Types of Caustic Soda

1. Flakes Caustic soda flakes are produced by evaporating water from a sodium hydroxide solution, leaving behind solid flakes. This form is highly concentrated and is often used in applications where a rapid dissolution is required. Caustic soda flakes are commonly used in the textile, pulp and paper, and soap industries. Due to their hygroscopic nature, they must be stored in airtight containers to prevent moisture absorption.

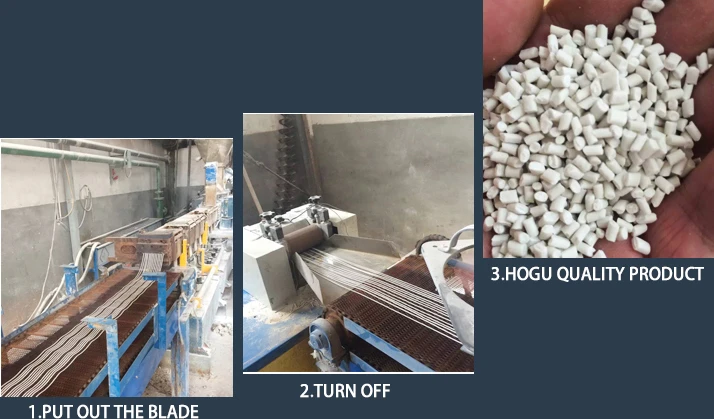

2. Pellets Similar to flakes, caustic soda pellets are also created from the evaporation of liquid sodium hydroxide. However, pellets typically have a more uniform size and shape, which makes them easier to handle and transport. They are favored in situations where precise measuring and concise packaging are vital. Caustic soda pellets are commonly utilized in the cleaning and maintenance of industrial equipment.

3. Liquid Liquid caustic soda is perhaps the most commonly used form in industrial applications. It is a concentrated solution of sodium hydroxide in water, typically available in different concentrations, ranging from 25% to 50%. The liquid form allows for easy mixing and application in processes such as wastewater treatment, where it is used to neutralize acids and adjust pH levels. Liquid caustic soda is also crucial in the production of biodiesel, as it acts as a catalyst in transesterification.

4. Beads Caustic soda beads are another form, combining features of both flakes and pellets. These small, round beads dissolve rapidly in water and are used in diverse applications, particularly in detergents and cleaning agents. Their structure allows for easier measuring and minimizes dust formation, making them a safer option for handling in various environments.

caustic soda types

Applications of Caustic Soda

Caustic soda is indispensable across multiple sectors. In the chemical industry, it serves as a base in the production of various chemicals such as chlorine, soap, and biodiesel. In the paper and pulp industry, caustic soda is employed in the pulping process, helping to break down lignin and separate cellulose fibers. In food processing, it is used in the manufacture of items such as olives and pretzels, contributing to texture and flavor enhancement.

Another critical area of application lies in water treatment. Caustic soda is used to raise the pH of drinking water, making it less acidic and thus more palatable. It also plays a role in neutralizing wastewater before discharge to meet environmental regulations.

Safety Considerations

While caustic soda is a valuable chemical, it must be handled with care. As a highly corrosive substance, it poses significant risks, including severe burns upon skin contact and respiratory issues if inhaled. Proper personal protective equipment (PPE), such as gloves, goggles, and respirators, should be utilized when handling caustic soda. Additionally, adequate training and safety protocols should be established to ensure safe storage and handling practices.

Conclusion

In conclusion, caustic soda is a crucial chemical with various forms, including flakes, pellets, liquid, and beads, each serving specific purposes in countless industries. Its applications range from manufacturing to water treatment, underscoring its significance in industrial processes. However, due to its hazardous nature, the importance of safety and proper handling cannot be overstated. Understanding the different types of caustic soda and their applications will help industries utilize this powerful chemical more effectively and safely.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025